Additive manufacture: a medical advance in 3D

At present the manufacturers are exploring the possibilities and the potential that offers the commonly called technology impressesion 3D, also known like additive manufacture, in which layers of material are deposited and melted there where requires using the power of the laser. They have manufactured plastic prototypes of this way during years. The difference is that now the additive manufacture is using for the manufacture of functional metallic pieces, often improved the provision of the same.

Some of the advantages are the minimum waste of material and the freedom of additional design like the possibility to generate reticular geometries or organic forms that challenge the conventional processes of manufacture. Even the language is changing: ‘mechanised' turns into ‘manufacture sustractiva', an alternative to the term ‘additive manufacture' employed by the pioneers of this new way, as

Additive manufacture at present into use

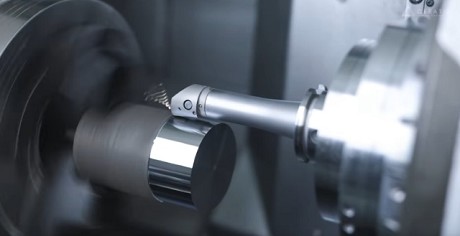

Renishaw Uses already the additive manufacture to manufacture dental rehabilitations and at present is contributing his years of experience to promote the adoption of this technology of manufacture. Using data 3D digital, the systems of fusion laser work depositing fine layers of dust of metal atomizado with gas, for later melt it there where was necessary using a laser guided of high power focalizado in a diameter of 70 μm. This layer of dust is melted in the surface, following a path 2D corresponding to the section of the piece, and with the consequent deposition of new layers.

The resultant components can have internal details complexes and combine solids with reticular structures. In orthopaedics, allows the creation of structures and surfaces that boost the osteointegración and opens the door to the economic production of personalised implants for each patient, particularly useful in the surgical reconstruction maxilofacial, where keep the facial osseous structure is paramount. Also it minimises the time in the operating theatre because the operations can schedule more easily by means of the use of existent additive technologies to re-create the osseous structure of the patient on which test the implant, ensuring the adjust and the functionality before the operation.

Adoption to world-wide level

Whereas the majority of systems of additive manufacture produce in Europe, Renishaw expects to contribute to and benefit of the increasing adoption of this technology in the rest of the world. The additive manufacture has attracted recently the attention of the government of the EE UU, with substantial sums of available federal bottoms create regional centres of excellence in the additive manufacture under the initiative of Obama of ‘can not expect'; similar projects exist in the rest of the world.

But exist barriers to the adoption. The acceptance depends on factors like the capacity to monitor the process with comparable norms to the ones of conventional technologies like the mechanised. Each field of application confronts to a series of challenges, from questions related with the accreditation and fulfillment with the rule, approval FDA or CE for implants and certification of the system according to the ISO 13485 and other norms.

Better use

The additive manufacture has been acclaimed like a form of repatriation of the processes of manufacture in the economies developed because of his nature of high technology and to the minimum waste of products, as well as to his potential credenciales ecological. A thing is true: the additive manufacture will not replace the conventional methods, will complement them. The paramount factor is that the best use of this technology attains in the stage of design of components and no by means of the application of the conventional designs to the process.

The acceptance will depend on that the designers explore the limits of the engineers of process and production, having the confidence in the capacity of the technology to produce compatible pieces with norms trazables.