Centres of CNC production for surgical instruments

April 15, 2009

Based on these framework conditions, for the mechanical production is a profile of requirements already cannot be met with "conventional methods and a simple standard CNC machines", according to said Otto Gäng, responsible for production of Paul Peschke. "Some of the pieces require up to 20 machining operations of narrow tolerances with a minimum holes, of which some will penetrate each other, with some even tiny milled, thread in miniature, etc." "This only possible with a safe process through complete machining in high precision machines and, if possible, a single subject".

From the German company, are required to used machines "a quick possibility of transformation, short times piece, a reliable process stability and a service of multiple shifts with a minimum of staff." "For our highly qualified employees we have tasks with more sense than the loading and unloading of machines".

Complete and integral machining of bars

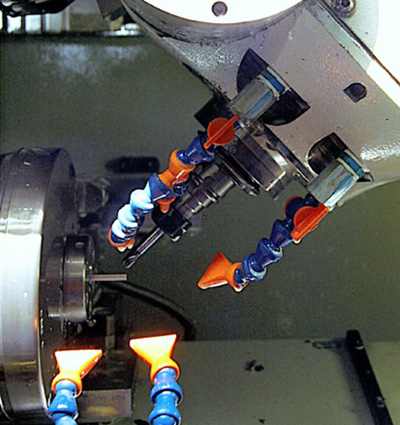

Equipped with Swivel Head, C axis and investment unit of parts, these production centres (in 2002 and 2004) enable the full and integral machining of bars. The only limitation for uninterrupted production performance is the step of 16 or 32 mm bars, which really is not also a real limitation, taking into account the wide range of parts. Otto Gäng says: "whereas the other centres of production work for the handling of several machines continuously in two shifts, the two machines of bars are almost always neglected 24 hours seven days a week".

The FZ 08 is not only a machine of compact series, but also a robust construction, good thermal stability and a well thought-out ergonomics. Typical way to Chiron FZ 08 range combines maximum dynamics and precision in a minimum of space. Quick marches of the routes of displacement X, and and Z (450 x 270 x 310 mm) speed up depending on the equipment of the machine with up to 2 grams to a maximum speed of 75 m/min. The 15,000 rpm spindle acceleration time is only 0.5 seconds. The change of tool for the storage of tools with 24 posts is just 0.8 seconds, allowing to reduce the chip/chip time of just 2.2 seconds.

According to Otto Gäng, "08 FZ series is designed for very fast production and highly accurate small pieces." Our production program currently includes about 500 different stainless steel and titanium pieces; more than 90% of all these pieces through our machines of Chiron. "Compared to a conventional production and through complete machining we have managed to reduce to half or less the time of production". In this sense, the operating times for handles with claws that were previously 10-12 minutes have been reduced to 4.5 minutes. In full production of endoscopic mouth pieces, Peschke has achieved a saving of up to 4.5 minutes per piece. But the short time per piece are not the only advantage. Responsible for production of Paul Peschke, Otto Gäng says: "We make a batch of 20 to 5,000 units sizes." "Once we have completed the filming of a new piece, a new preparation of machines required depending on the machines half an hour at most". In the case of times piece that vary from 3.5 to 10 minutes, the share of transformation remains reasonable, even in small batches.

Apparently, the use of systems or even buckets of multiple subject in the centres of production of four axes does not make sense for Peschke. Otto Gäng refelxiona: "what I for a device subject to, for example, 20 pieces, whose processing takes approximately an hour and a half if then I need a whole shift for the preparation and transformation?" "Our sophisticated systems of individual subject enable us to be fast, flexible and economic".

What happens in the case of larger quantities?