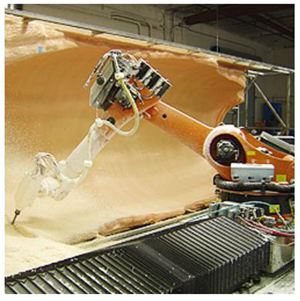

Célula CNC de fresado de Robotics Solutions

Automatización del fresado de elementos estructurales de gran formato mediante un robot Kuka de 6 ejes

Robotics Solutions, Inc. suministró a Guy Martin Design una versión adaptada de su célula de mecanizado estándar RMC 100-RTSL. El sistema 100-RTSL aplica un concepto sencillo e innovador que se caracteriza por su fácil manejo gracias al cambio rápido y flexible de las herramientas. Las longitudes y dimensiones de las herramientas son registradas con ayuda de un sistema de palpado por láser y programadas mediante un sistema CAM. Así, la instalación corresponde a una máquina-herramienta estándar con la flexibilidad de un robot Kuka de 6 ejes. La instalación de Guy Martin Design integra un robot Kuka del tipo KR 100 L80 HA, montado sobre una unidad lineal KL 1500 que ofrece un recorrido de 13 metros.

Para el mecanizado de conceptos tridimensionales detallados, la instalación se ayuda de una mesa giratoria, integrada como octavo eje en la unidad de control Kuka. El empleo de la mesa giratoria depende de los requisitos del proyecto. La instalación de Guy Martin Design funciona como un centro de mecanizado CNC de 5 ejes que opera con el software CAM PowerMILL de Delcam. Las trayectorias de mecanizado generadas por el software PowerMill a una excepcional velocidad de cálculo permiten mecanizar piezas de filigrana extremadamente complejas en una célula RMC. La instalación de Guy Martin Design incluye, además, un cambiador de herramientas de 10 posiciones que acompaña al robot en su movimiento sobre el eje lineal. Esto permite tener las herramientas siempre al alcance. Las pistolas aplicadoras de resina sintética o fibra de vidrio están integradas en el cabezal del robot, lo que permite ahorrar tiempo y espacio

Resultados de éxito

Gracias a la nueva célula CNC de fresado de Robotics Solutions, Inc., Guy Martin Design dispone de una instalación capaz de fabricar de forma rápida, precisa y detallada piezas de distinto tamaño y material y afrontar proyectos futuros ahorrando espacio y tiempo en comparación con otras soluciones. Sobre la colaboración con Kuka, el Sr. Wenzel, CEO de Guy Martin Design, explica: "Los profundos conocimientos y el amplio espectro de prestaciones de servicio del equipo de Kuka Robotics nos reforzó a la hora de tomar una decisión. No hubo ninguna otra empresa especializada en robótica que pudiera hacernos una oferta comparable ni mostrarnos tal disposición a elaborar aplicaciones fuera de lo normal”.