Estudio del impacto ambiental del cultivo de tomate en un invernadero multitúnel

El escenario para el estudio fue la costa de Almería, España. Se eligió un invernadero multitúnel sin calefacción, un sistema pasivo que necesita poca energía, y cuyos insumos más importantes son los fertilizantes y el agua. La infraestructura del invernadero consta de un armazón de acero, con techo en forma curva, y una cubierta de plástico. Este estudio se realizó aplicando la metodología del Análisis de Ciclo de Vida (ACV). Se definieron los límites del sistema, desde la extracción de materias primas hasta la obtención de la cosecha, incluyendo la gestión de los residuos generados y excluyendo la comercialización. El sistema estudiado se modeló considerando los siguientes subsistemas: la estructura, el equipo auxiliar, el sistema de control climático, los fertilizantes, los plaguicidas y la gestión de los residuos.

Los resultados de la evaluación ambiental indicaron que las principales cargas ambientales fueron la estructura, el equipo auxiliar y los fertilizantes. La estructura fue la mayor carga ambiental debido a la gran cantidad de acero en el armazón. La gran contribución del equipo auxiliar se debió a la fabricación del sustrato (perlita) y al consumo de electricidad para el funcionamiento del sistema de riego. El uso de fertilizantes provocó importantes impactos ambientales como resultado tanto de los procesos de fabricación de los fertilizantes como de las emisiones debidas a su uso. Las principales recomendaciones que se proponen a partir de los resultados están orientadas a reducir estos impactos. Aumentar la productividad y alargar la vida útil del invernadero podrían reducir directamente las cargas ambientales por unidad de producto. Reducir el volumen de sustrato por planta y reciclar el sustrato utilizado son propuestas adicionales. Finalmente, dado que el sistema analizado era un cultivo sin suelo con sistema de riego abierto, se propone optimizar el aporte de los fertilizantes y el agua.

Introducción

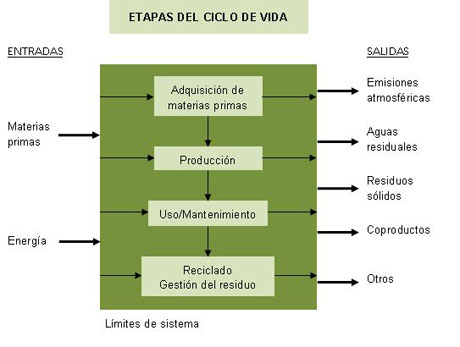

La expansión de la horticultura protegida en el área mediterránea ha significado un progreso económico importante, especialmente en zonas marginales. El clima cálido permite la producción de cultivos en invernadero con bajos requerimientos de energía. Sin embargo, con el aumento de los cultivos protegidos y la sensibilización por parte de los consumidores por los aspectos medioambientales, es importante analizar los daños ambientales que se producen a lo largo de todo el proceso de cultivo. Este estudio se desarrolló con el fin de detectar los puntos ambientales débiles de la producción de tomate en un invernadero multitúnel en un clima mediterráneo. Este trabajo es parte del proyecto Euphoros (Euphoros, 2008-2012), que tiene como objetivo desarrollar un invernadero sostenible, que haga un uso eficiente de los recursos, con una reducción de los aportes externos pero manteniendo una alta productividad. El sistema estudiado abarcó todo el ciclo de vida del cultivo, desde la extracción de materias primas hasta la producción de tomates y la eliminación de los materiales de desecho. Para evaluar el impacto ambiental se utilizó la metodología del Análisis de Ciclo de Vida (ACV), una herramienta útil, adoptada internacionalmente para estudiar los aspectos ambientales y los impactos potenciales a lo largo de todo el ciclo de vida de un producto o actividad, incluyendo las etapas de adquisición de las materias primas, producción, uso y eliminación de residuos.

Estudios similares en condiciones de invierno templado se han realizado en Cataluña (Antón et al., 2005), las Islas Canarias (Torrellas et al., 2008) y Granada (Romero-Gámez et al., 2009). Sin embargo, este es el primero que se centra en Almería. Los cultivos protegidos en la cuenca del Mediterráneo ocupan aproximadamente 170.000 ha y España cuenta con la mayor superficie de cultivos protegidos en Europa con 50.365 hectáreas de invernaderos. Las mayores áreas de invernaderos en España se sitúan en las costas de Almería, Murcia y Granada, en el sudeste de la Península Ibérica, y las Islas Canarias en el Océano Atlántico. Almería cuenta con casi el 60% de la superficie de invernaderos en España. El cultivo de tomate es uno de los más importantes (EFSA-PPR, 2009).

Materiales y métodos

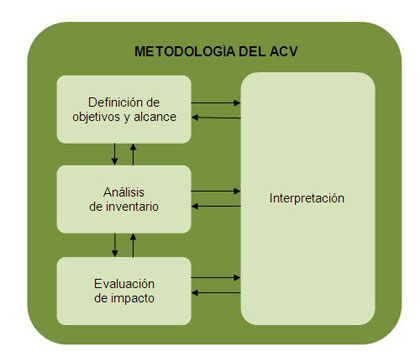

El objetivo de este estudio fue evaluar los impactos ambientales de la producción actual de tomate en un invernadero multitúnel en clima mediterráneo, y detectar los principales daños que podrían reducirse mediante la aplicación de los nuevos avances tecnológicos que se desarrollarán en el curso del proyecto Euphoros. Para la evaluación de impactos se utilizó la herramienta del Análisis de Ciclo de Vida (ACV). Esta técnica evalúa los impactos ambientales potenciales a lo largo de todo el ciclo de vida de un producto, servicio o proceso, “de la cuna a la tumba”. Esto quiere decir que el estudio incluye (Figura 1), además de la fabricación del producto en sí, la producción de sus materias primas, su uso y mantenimiento, y la gestión del residuo una vez ha acabado su vida útil (Puig et al., 2005). Según lo definido por la norma ISO 14040 (ISO-14040, 2006) el ACV es una “compilación y evaluación de las entradas, salidas y los impactos ambientales potenciales de un sistema de producto a lo largo de su ciclo de vida”.

Los primeros estudios de ACV se realizaron para analizar procesos industriales. La acción concertada “Harmonization of environmental LCA for Agriculture” (Audsley, 1997) puede ser considerada como el primer intento de adaptar dicha metodología a la agricultura. Las primeras aplicaciones de ACV en agricultura se llevaron a cabo en productos procedentes de la agricultura extensiva y ganadería. En estos trabajos generalmente se comparan métodos de producción convencional y ecológica. Posteriormete, los ACV se extendieron a la obtención de productos procesados: leche, mantequilla, pan, etc. (Antón, 2008).

De acuerdo con la metodología propuesta por la normativa ISO 14040, un proyecto de ACV se divide en cuatro fases: objetivos y alcance del estudio, análisis de inventario, análisis del impacto e interpretación (Figura 2). Estas cuatro fases son iterativas y esto permite ir incrementando el nivel de detalle del estudio.

La fase objetivo y alcance del estudio define el tema de estudio e incluye los motivos que llevan a realizarlo. También es la fase en la que se define la unidad funcional (UF). La unidad funcional refleja la función principal del sistema y sirve como referencia para cuantificar las entradas y salidas del sistema. Dado que la función principal de un invernadero es producir, en este estudio se tomó como unidad funcional la producción de tomates. La UF seleccionada fue 1 tonelada de tomates.

Un invernadero multitúnel en la costa de Almería (España) fue el escenario para el estudio. Este tipo de invernadero está formado por una estructura de acero, de techo arqueado, y una cubierta de plástico. Debido a su naturaleza global, un ACV completo puede resultar extensísimo. Por esta razón se deberán establecer unos límites perfectamente identificados. Los límites del sistema determinan los procesos que se incluyen en el sistema de producción. En el presente estudio estos límites se definieron desde la extracción de materias primas hasta la salida del invernadero, incluyendo la gestión de los residuos generados. Las etapas posteriores de envasado y comercialización no se tuvieron en cuenta. Los procesos que se incluyeron en el análisis ambiental fueron: la extracción de materias primas, la fabricación de los componentes del invernadero, el transporte de materiales, la eliminación de residuos, y el consumo de energía, agua, fertilizantes y plaguicidas.

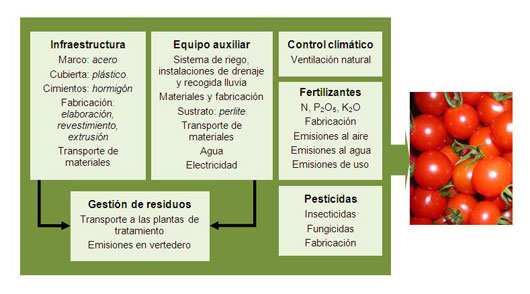

La fase del análisis de inventario (ICV) comprende tanto la obtención de datos como los procedimientos de cálculo para identificar y cuantificar todos los efectos ambientales adversos asociados a la unidad funcional. De una forma genérica denominaremos estos efectos ambientales como “carga ambiental”. Se considera carga ambiental la salida o entrada de materia o energía de un sistema que causa un efecto ambiental negativo. Con el fin de facilitar el análisis de inventario y la interpretación de los resultados, el sistema de producción se ha estructurado en los siguientes subsistemas: la estructura del invernadero, el equipo auxiliar, el sistema de control climático, los fertilizantes, los plaguicidas y la gestión de los residuos (Figura 3).

Los datos referentes a las operaciones agrícolas, tales como las dosis de fertilizantes o el consumo de agua, fueron recogidos por la Estación Experimental de la Fundación Cajamar (EEFC) (Fundación_Cajamar, 2008), El Ejido, Almería. La estructura del invernadero se modeló a partir de un conjunto de datos que caracterizan la estructura típica de un invernadero multitúnel. Se utilizaron de bases de datos Ecoinvent (ecoinvent, v2.2, 2010) y LCAFoods (Nielsen et al., 2003) para obtener los datos que se refieren a los procesos de fabricación de los materiales que intervienen en el invernadero, del sustrato, de los fertilizantes y los plaguicidas, de la producción de electricidad, del transporte de los materiales y de los procesos de tratamiento de residuos. La herramienta informática utilizada para la evaluación ambiental fue el programa SimaPro versión 7.2 (PRéConsultants, 2010).

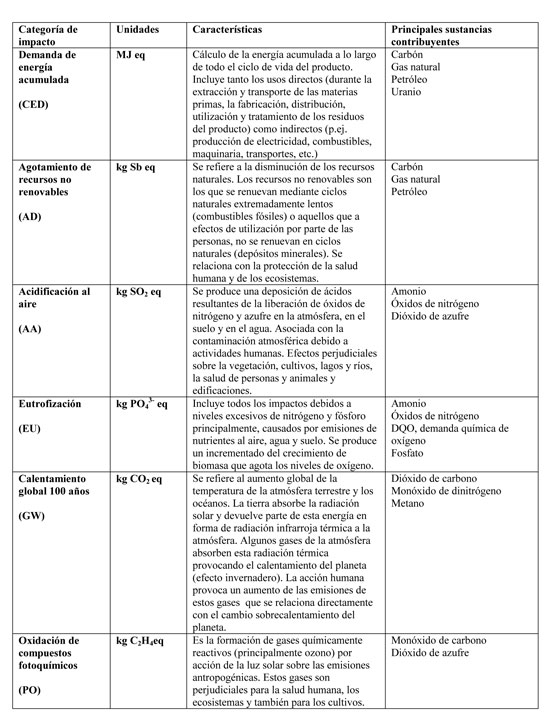

En un estudio de ACV es necesario seleccionar los indicadores y las categorías de impacto (Tabla 1). Un indicador de categoría es una representación cuantitativa de una categoría de impacto. Una categoría de impacto es una clase que representa aspectos de interés ambiental y a la que se asignan los resultados del análisis de inventario. Las categorías de impacto seleccionadas para la evaluaciónambiental fueron:

- Demanda de energía acumulada, CED (MJ eq) (Frischknecht et al., 2005), como el indicador de flujo de energía, y cinco categorías de impacto definidas por el método CML2001 v. 2.05 (Guinée et al., 2002.)

- Agotamiento de recursos no renovables AD, (kg Sb eq)

- Acidificación del aire, AA (kg SO2eq)

- Eutrofización EU (kg PO4-3 eq)

- Calentamiento global, GW (kg CO2 eq) y

- Formación de oxidantes fotoquímicos, PO(kg C2H4 eq).

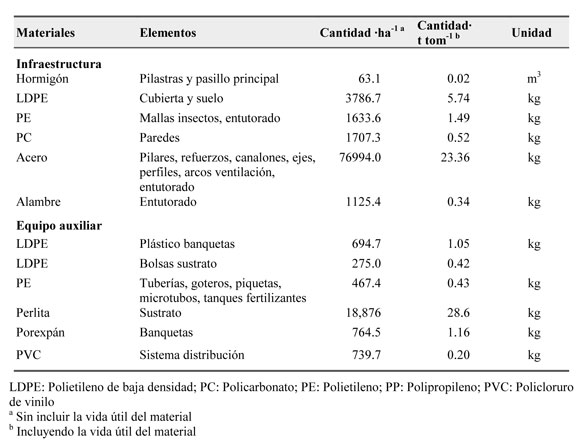

La vida útil del invernadero se estimó en 15 años, de acuerdo con las directrices del Comité Europeo de Normalización (CEN, 2001). El análisis de inventario fue preparado según Audsley (1997), Antón (2004) y las normas ISO (ISO-14040, 2006). Se consideraron los procesos de fabricación delos elementos de acero y plástico. Se estimó que el acero se había fabricado a partir del reciclaje de residuos de acero. También se incluyó el proceso de galvanizado de la superficie.

Las principales características de los subsistemas definidos fueron:

- Estructura: Los elementos de acero incluidos fueron pilares, refuerzos del armazón, canalones, crucetas, perfiles, arcos y ventanas. El sistema de entutorado era de alambre, y la cubierta y el suelo acolchado de polietileno de baja densidad. Las paredes frontales y laterales estaban hechas de lámina de policarbonato y las mallas antiinsectos de las ventanas de polietileno. Las pilastras y pasillo principal eran de hormigón (Tabla 2).

- Equipo auxiliar: Este incluía el sistema de riego, las instalaciones de drenaje y recogida de agua de lluvia, el consumo de electricidad por el sistema de riego y el sustrato. Se utilizó un sistema de riego por goteo sin recirculación del agua de drenaje.Las banquetas, protector de banquetas, tuberías, goteros, piquetas, microtubos y tanques de fertilizantes eran de plástico, y los inyectores y bombas de acero. El sustrato utilizado fue perlita dispuesta en bolsas de polietileno, con tres plantas en cada una de ellas. La densidad del cultivo fue de 1.2 plantas•m-2, con 2 tallos por planta. El período de cultivo fue de septiembre 2007 a junio 2008, dando un rendimiento de 16,5 kg•m-2. La cantidad total de agua consumida fue 4.748 m3•ha-1, de la cual un 25% era de lixiviación. Por consiguiente, el consumo del agua fue de 28,8 l•kg tomate-1.

- Sistema de control climático: Como en la mayoría de los invernaderos mediterráneos, no existe un sistema de calefacción y sólo se lleva a cabo una ventilación natural. En este subsistema sólo se consideró el consumo de electricidad para el funcionamiento de las ventanas cenitales.

- Fertilizantes: Las cantidades totales de N, P y K aplicados al cultivo fueron: 798.4 kg•ha-1 de N, 220.8 kg•ha-1 de P, 1.296,3 kg• ha-1 de K. Se calcularon las emisiones al aire de NH3-N, N-N2O y NOx-N y las emisiones al agua de NO3-N (Audsley, 1997; Brentrup et al., 2000.), También se incluyeron las emisiones producidas durante el proceso de fabricación.

- Plaguicidas: Se consideró la cantidad total de principio activo para los insecticidas (3.8 kg•ha-1) y fungicidas (28.5 kg•ha-1). La fabricación de los plaguicidas y el uso de maquinaria para su aplicación también se incorporaron al inventario. La toxicidad de los plaguicidas no se incluyó ya que no hay un consenso general para su evaluación.

- Gestión de residuos: Incluyó diversos tratamientos para los materiales de desecho. El metal y policarbonato fueron 100% reciclados. El 50% del hormigón y el sustrato fueron reciclados y el restante 50% depositados en vertedero. El 90% de los plásticos se reciclaron y el 10% transportados al vertedero. La biomasa verde fue tratada en la planta de compostaje teniendo en cuenta el 40% del peso fresco total en el momento del transporte. Sólo se consideraron las emisiones debidas al transporte al vertedero y a la planta de compostaje, y las emisiones debidas a la deposición en vertederos. El transporte a las plantas de reciclaje y los procesos de reciclado no fueron considerados en el sistema. Se estimaron diferentes vidas útiles en función de cada material: 15 años para los metales, PC y hormigón; de 3 a 5 años para los plásticos, y 3 años para el sustrato de perlita.

Resultados y discusión

En esta sección se incluye la fase de análisis del impacto de ciclo de vida (AICV). Los resultados de la evaluación ambiental muestran los impactos ambientales potenciales de las entradas y salidas en la fase de inventario del sistema. Las principales cargas ambientales detectadas en el ciclo de vida del sistema de producción de tomate fueron la estructura, el equipo auxiliar y los fertilizantes.

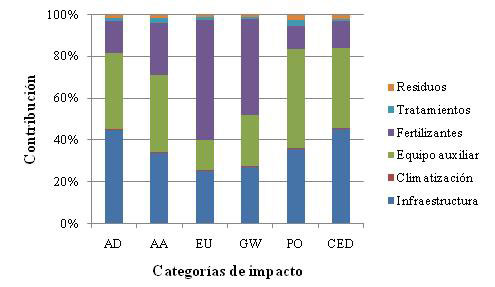

En el sistema de producción, la estructura fue la carga principal para las categorías de impacto Agotamiento de recursos no renovables y Demanda de energía acumulada, con una contribución del 45% y 46% del total. El equipo auxiliar mostró las mayores contribuciones para las categorías ‘Acidificación del aire’ y ‘Formación de oxidantes fotoquímicos’, con un 37% y 47% del total, y los fertilizantes para las categorías ‘Eutrofización’ y ‘Calentamiento global', con 58% y 46% respectivamente. Las contribuciones del sistema de control climático, los plaguicidas y la gestión de residuos fueron inferiores al 3 % del total (Fig. 4).

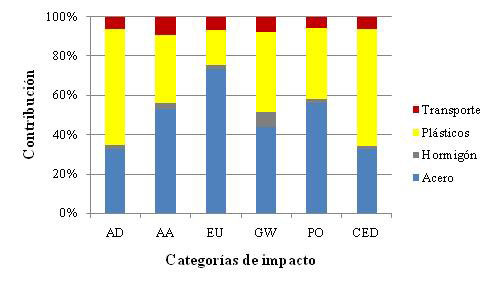

La alta contribución de la estructura fue entre 44% y 74% para las categorías de impacto ‘Acidificación’, ‘Eutrofización’, ‘Calentamiento global’(GW) y ‘Formación de oxidantes fotoquímicos’, debido a la gran cantidad de acero en el armazón. Los plásticos fueron las principales cargas para la categoría ‘Agotamiento de recursos no renovables’ y la ‘Demanda de energía acumulada’ (ambas 59%) (Fig. 5). Los resultados están de acuerdo con los de Cowell (1998), quien destacó la importancia de la contribución de la infraestructura a los impactos ambientales globales en los sistemas agrícolas, a diferencia de muchos edificios en los sistemas industriales. Los bajos requisitos de energía para el proceso de cultivo y el período de vida más corto del invernadero en comparación con los edificios industriales hacen destacar el impacto de la estructura.

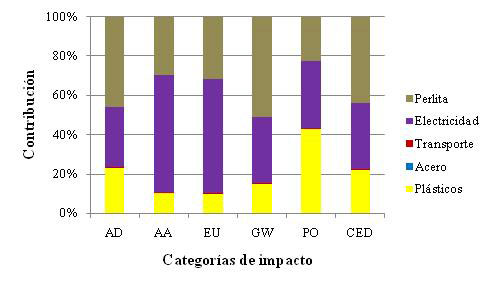

La fabricación de la perlita y el consumo de electricidad fueron las mayores cargas ambientales en el subsistema equipo auxiliar(Fig. 6). En el primer caso debido al consumo de gas natural para la expansión de la perlita y en el segundo por el consumo producido para bombear el agua.

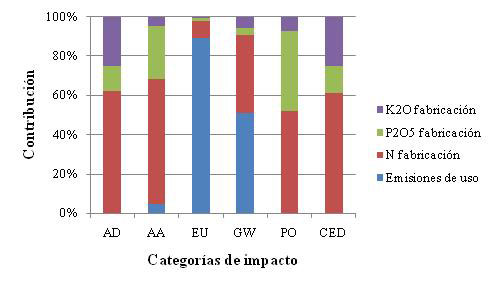

Los impactos ambientales de los fertilizantes fueron debidos a las emisiones producidas durante su fabricación y su aplicación (Fig. 7). La producción de los fertilizantes de N tuvieron las contribuciones más altas para la mayoría de las categorías de impacto, excepto para la EU y GW, 52% y 64%. Las emisiones debidas al uso de fertilizantes fueron las más altas para las categorías Eutrofización y Calentamiento global, debido en gran parte a las emisiones de NO3 al agua de los lixiviados para la categoría de Eutrofización y las emisiones de N2O, un gas de efecto invernadero importante, para la categoría de Calentamiento global. En lo que respecta al riesgo de eutrofización, cabe señalar que las metodologías utilizadas actualmente para evaluar la cantidad de fertilizante que llega a los acuíferos son sólo aproximadas y sujetas a debate. También se ha demostrado que existe un amplio margen para la reducción de las dosis de fertilizantes aplicados (Muñoz et al., 2008).

Interpretación

Las conclusiones obtenidas a partir de los hallazgos en la fase de inventario y de los resultados de la evaluación de impacto del ciclo de vida se orientan a reducir los impactos ambientales y a mejorar los sistemas de producción. La evaluación ambiental de la producción en invernadero multitúnel se utilizará para evaluar la posible reducción de las cargas ambientales en estudios posteriores, mediante la aplicación de mejoras potenciales que se desarrollarán a lo largo del proyecto Euphoros.

Una forma obvia de reducir los impactos sería aumentando la productividad y extendiendo la vida útil del invernadero. Se consideró una vida útil de 15 años para el invernadero, pero es una práctica común que los productores alarguen esta vida útil. Las cargas de la estructura podrían reducirse mejorando el diseño del invernadero, incluyendo materiales reciclados o reutilizados en los procesos de fabricación. En los invernaderos del Mediterráneo, cualquier mejora tecnológica aplicada a un invernadero pasivo se traducirá en la reducción de la carga ambiental asociada a la infraestructura.

Se encontró un elevado consumo de energía para la fabricación de la perlita y para el funcionamiento del sistema de riego. El uso de la energía solar, almacenamiento térmico y otras energías renovables podría contribuir a la reducción de los impactos ambientales del consumo de energía en la producción de tomate. Con el fin de reducir los impactos ambientales asociados al sustrato, se deberían orientar los esfuerzos a los procesos de reducción del volumen de sustrato utilizado en el cultivo y reciclado.

La reducción de la dosis de fertilizante tendría un efecto directo en la disminución del riesgo de eutrofización en un sistema sin suelo y abierto. Un sistema de riego de circuito cerrado es también una buena opción a considerar. Las investigaciones futuras se dirigen a evaluar la reducción de los impactos ambientales con la aplicación de nuevas mejoras desarrolladas durante el proyecto Euphoros.

Agradecimientos

Este estudio forma parte del proyecto de investigación Euphotros (Efficient use of inputs in protected horticulture - FP7-KBBE-2007-1), financiado económicamente por la Unión Europea.

Bibliografía

- Antón, A. 2004. Utilización del Análisis del Ciclo de Vida en la Evaluación del Impacto ambiental del cultivo bajo invernadero Mediterráneo. Tesis doctoral, Universitat Politècnica de Catalunya, Barcelona.

- Antón, A., Montero, J.I., Muñoz, P. 2008. XXXVIII Seminario de Técnicos y Especialistas en Horticultura, Sitges, Nov 2008.

- Antón, A., Montero, J.I., Muñoz, P. and Castells, F. 2005. LCA and Tomato Production in Mediterranean Greenhouses. International Journal of Agricultural Resources Governance and Ecology 4:102-112.

- Audsley, E. 1997.Harmonisation of Environmental Life Cycle Assessment for Agriculture.Final Report Concerted action AIR3-CT94-2028. European Commission DG VI Agriculture.

- Brentrup, F., Küsters, J., Lammel, J. and Kuchlmann, H. 2000.Methods to estimate On-field Nitrogen emissions from crop production as an input to LCA studies in the agricultural sector. The International Journal of Life Cycle Assessment 5 349-357.

- CEN, 2001, EN 13031. Greenhouses: Design and consrucion – Part 1: Commercial production greenhouses. Euroean Committee for Standardization.

- Clemente, G., Sanjuán, N., Vivancos, J.L. 2005.Análisis de Ciclo de Vida: Aspectos Metodológicos y Casos Prácticos. Ed. Universidad Politécnica de Valencia.

- Cowell, S.J. 1998. Environmental Life Cycle Assessment of Agricultural Systems: Integration Into Decision-Making. Ph. D. thesis, University of Surrey, Guildford.

- Ecoinvent. 2010. Ecoinvent Data v2.2. Swiss Centre for Life Cycle Inventories.

- EFSA-PPR. 2009. EFSA-PPR project on “Data-collection of existing data on protected crop systems (greenhouses and crops grown under cover) in Southern European EU Member States”. Agricultural University of Athens, Athens.

- Euphoros. 2008-2012. Efficient use of inputs in protected horticulture [Online].

- Frischknecht R, Junblugth N, Althaus H-J, Doka G, Dones R, Heck T, Hellweg S, Hischeir R, Nemecek T, Rebitzer G, Spielmann M, Wernet G. 2005. The Ecoinvent Database: Overview and Methodological Framework. International Journal of Life Cycle Assessment10 (1) 3-9.

- Fundación_Cajamar. 2008. Analisis de la campaña Hortofrutícola de Almería, Campaña 2007/2008. Informes y Monografias., Almería.

- Guinée, J.B., Gorrée, M., Heijungs, R., Huppes, G., R., K., de Koning, A., Wegener Sleeswijk A., Suh, S., Udo de Haes, H., Bruijn, H., Duin, R.v. and Huijbregts, M.A.J. 2002. Handbook on life cycle assessment.Operational guide to the ISO standards Kluwer, Dordrecht, The Netherlands.

- ISO-14040. 2006. Environmental management-Life cycle assessment-Principles and framework. International standard 14040. International Organisation for Standardisation ISO, Geneva.

- Muñoz, P., Antón, A., Paranjpe, A., Ariño, J. and Montero, J.I. 2008. High decrease in nitrate leaching by lower N input without reducing greenhouse tomato yield. Agronomie and Sustainable Development 28:489–495.

- Nielsen, P., Nielsen, A., Weidema, B., Dalgaard, R. and Halberg, N. 2003. LCA food data base. [Online] www.lcafood.dk.

- PRéConsultants. 2010. SimaPro 7.2, Amersfoort. The Netherlands.

- Puig, R., Milà, L., Fullana, P. 2005. Análisis de Ciclo de Vida: Aspectos Metodológicos y Casos Prácticos. Ed. Universidad Politécnica de Valencia.

- Romero-Gámez, M., Antón, A., Soriano, T., Suárez-Rey, E. and Castilla, N. 2009. Environmental impact of greenbean cultivation: Comparison of screen greenhouses vs. open field Journal of Food, Agriculture & Environment 7:132-138.

- Torrellas, M., de León, W., Raya, V., Montero, J., Muñoz, P., Cid, M. and Antón, A. 2008. The 8th International Conference on EcoBalance, Tokyo, Japan. 10-12 Dec. p. P-041.