Envases de lino, cáñamo o algodón

30 de marzo de 2002

La tecnología "Double Twist" permite utilizar materiales naturales como algodón, cáñamo o lino para tejer y que la malla resultante sea resistente a la rotura. Verpackungs Zentrum Graz (www.vpz.at), una empresa austríaca, fabrica sacos de este tipo y explica que son tan fiables como los de malla para utilizar con máquinas de envasdo automático.

|

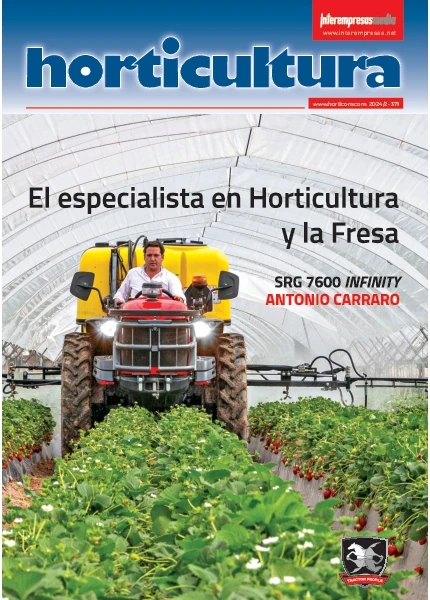

La tecnología "Double Twist" permite utilizar materiales naturales como algodón, cáñamo o lino para tejer y que la malla resultante sea resistente a la rotura. Verpackungs Zentrum Graz (www.vpz.at), una empresa austríaca, fabrica sacos de este tipo y explica que son tan fiables como los de malla para utilizar con máquinas de envasdo automático. La cinta de cierre también es reciclable y, por tanto, ecológica. En la imagen, tomada en Biofach 2002 (www.nuernbergmesse.de) 2002 (febrero, Nürenberg), Bettina Reichl, Helmut Reichl y Susanne Meininger.

En la página web de la empresa existe un vínculo a http://www.transpackaging.at/, una página web en alemán dedicda a materiales de envasado "ecológicos".

Más información a continuación, en la versión en inglés; follows more information, on the English version.

Compostable Net- and Textile-Sacks in the new Double-Twist Technology

A product from Verpackungszentrum Graz (www.vpz.at)

Textiles in the new Double-Twist Technology provide yet another proof that the use of natural materials during the whole of a production cycle not only protects the environment but also, and above all, means that “a better product” can be offered to the consumer. Expressed simply, in this new weaving process (Double-Twist Technology) each thread is twisted twice round the other threads, whereby, using less material than before, a considerably greater degree of tensile strength is achieved. The use of natural materials on the one hand and the considerably increased tensile strength achieved by the use of Double-Twist Technology on the other hand mean that the new textiles have a wide field of application.

At the present time, Verpackungszentrum Graz is concentrating on the production of net sacks and textile sacks suitable for the packaging of fruit and vegetables or of seed. Currently, net sacks world-wide are 95% made out of synthetics.

- · During production on mechanical weaving machines, there is only a minimum of emissions. In the production of sacks from synthetics, waste (PE-Foils) amounts to up to 25%, whereas the Double-Twist process causes waste only up to 10%.

- · A patented loop permits sacks also to be filled using automatic machines (product in rolls). In contrast to synthetics sacks produced by a knitting process (HDPE Raschel Net Bags), our process does not permit the formation of “stocking ladders” through which product can escape. It is therefore possible to avoid stoppages of automatic filling machines, loss of product and unnecessary waste. In the Double-Twist Process only a few threads of an individual sack can be damaged but not a complete roll of sacks.

- · Minor adjustments in the process allow of a wide variety of types of weave ranging from broad-mesh to opaque. Also a combination of various thread colours and types of weave within the individual sack is possible. “See-through” windows and logos can be directly weaved into sacks. Individual sacks are equipped with a draw-string and can be re-used several times.

- · The sacks can be made of self-regenerative raw materials such as hemp, flax, cellulose and cotton and this saves wasting valuable mineral oil reserves. Natural fibres regulate humidity and allow “natural breathing”, and it has been proved that fruit and vegetables stay fresh longer when packed in natural fibres e.g. there is less premature sprouting of onions and potatoes and less formation of mould.

- · The increased consumer demand for biological foodstuffs means that there is a larger market for biogenic packaging because this reinforces the appearance of the product at the POS.

The product received a nomination in 2000 for the Austrian State Prize for exemplary packaging and was awarded the Austrian Eco-Design-Prize in 2001.