Comunicación sin límites

Garantizar el desarrollo de software sostenible para los fabricantes de maquinaria y ofrecer a los usuarios ventajas estratégicas en el mercado global: éstos son los objetivos del entorno de desarrollo Automation Studio de B&R. Cuando se trata de gestionar la comunicación desde el nivel de proceso hasta el nivel de la empresa, B&R se basa en OPC Unified Architecture o, lo que es lo mismo, OPC UA. Este protocolo ofrece funciones fáciles de usar para acceder a los datos y a los programas independientemente de la plataforma utilizada, haciendo la vida mucho más fácil a los ingenieros de aplicaciones a lo largo del proceso.

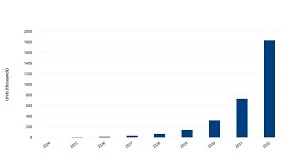

La complejidad de las tareas de automatización industrial es cada vez mayor, lo cual conlleva al desarrollo de más conceptos de control cada vez más distribuidos. Estos enfoques permiten una tecnología de automatización más individual, flexible y estructurada modularmente, ya que los dispositivos periféricos inteligentes conectados a través de Ethernet industrial cada vez son más frecuentes. Cada vez es más común, por ejemplo, equipar piezas o componentes individuales de la máquina con sus propios controladores y agruparlos para formar una máquina completa.

Comunicación fluida

Una comunicación eficaz entre los subsistemas y los componentes individuales es de crucial importancia para la productividad de este tipo de soluciones. En los primeros días de la electrónica industrial, los sistemas se comunicaban utilizando interfaces o controladores de dispositivo programados de forma individual. Hace casi dos décadas, la industria de la automatización comenzó a buscar formas de ofrecer interoperabilidad sin necesidad de programación de aplicaciones. Un ejemplo de ello, es OLE (Object Linking and Embedding), un protocolo de intercambio de datos desarrollado por Microsoft en 1992 para aplicaciones de oficina que radica directamente en el sistema operativo. OLE permite acciones como la integración de los valores a partir de fuentes de datos externas en tablas o la incorporación de tablas e imágenes en los documentos. A continuación, se desarrollaron interfaces de software estandarizados para el intercambio de datos entre aplicaciones de diferentes fabricantes, basándose en este protocolo, que se introdujeron en el año 1996 bajo el nombre de OPC (OLE for Process Control). Desde 1998, también se han incluido en Automation Runtime, el sistema operativo en tiempo real de B&R.

Un sistema, muchos fabricantes

Los fabricantes de dispositivos finales utilizados en la automatización industrial pueden configurar un servidor OPC para aprovechar los datos de los clientes OPC en los controladores, sistemas Scada y dispositivos HMI. OPC es muy fácil de utilizar, como lo demuestran los controladores que se entregan con las impresoras de oficina que han permitido la integración de las mismas en el entorno de oficina de Windows. “Esto ha reducido considerablemente la cantidad de esfuerzo que se requiere para programar tareas de comunicación”, explica Hans Egermeier, director de la Unidad de Negocio Automation Software de B&R. “Lo más importante, sin embargo, es que permitió desarrollar sistemas distribuidos con el software y los dispositivos de diferentes fabricantes de forma rentable, tal y como es habitual hoy en día”. El desarrollo de software para productos compatibles con OPC se basa en otra tecnología de Microsoft para un marco común: COM/DCOM (Distributed Component Object Model). Por un lado, esto ofrece la ventaja de una plataforma tecnológica con un alto grado de estabilidad debido a su amplia distribución. Por otro lado, sin embargo, los desarrolladores se enfrentan a las limitaciones del DCOM, como una configuración muy lenta, sin la posibilidad de establecer parámetros de tiempo ni de habilitar características de alta disponibilidad. Otros puntos en contra incluyen estar atado al sistema operativo Windows y una falta de control debido a la naturaleza propietaria de COM/DCOM. Además, un servidor OPC se debe configurar en un hardware de PC compatible con Windows por separado con el fin de implementar un sistema de comunicación con OPC.

OPC permite desarrollar sistemas distribuidos con el software y los dispositivos a distintos fabricantes.

Cualquier plataforma

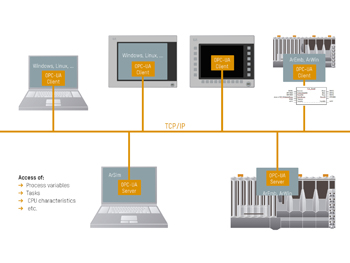

La superación de todos estos defectos fue el objetivo de la OPC UA (Unified Architecture), la especificación de la cual se completó en 2009 por parte de OPC Foundation. Esta tecnología combina las especificaciones previamente separadas para datos, eventos, objetos o comandos en un solo estándar unificado. OPC UA también cuenta con una arquitectura orientada a servicios (SOA) con varias capas de comunicación y una pila de comunicación por separado para reemplazar la tecnología COM/DCOM anterior. Esto no sólo hace que sea más fácil de portar a diferentes tecnologías, sino que también permite el intercambio seguro, fiable e independiente de la plataforma de los datos primarios y la información preprocesada entre el nivel del dispositivo de campo y la planificación de la producción y sistemas ERP. Disponible en ANSI C, C# y Java, la pila de comunicación OPC UA puede portarse a cualquier sistema operativo o hardware embebido y compilarse para su uso en operaciones multihilo o de una sola tarea. Esto permite que cualquier dispositivo final inteligente actúe como un servidor OPC UA independientemente del fabricante, el lenguaje de programación y el sistema operativo, con lo cual no es necesario un PC intermediario. “OPC UA proporciona escalabilidad completa: desde el software de control integrado hasta los sistemas de información de gestión", comenta Egermeier. El estándar de comunicación OPC UA no sólo ofrece un sistema de autenticación separado basado en tareas según los estándares actuales, sino que también permite conexiones seguras certificadas y una configuración completamente transparente en todo el proceso. También permite dividir grandes paquetes de datos para que sean manejables para sistemas más pequeños a través de la fragmentación.

Protección de la inversión con OPC UA

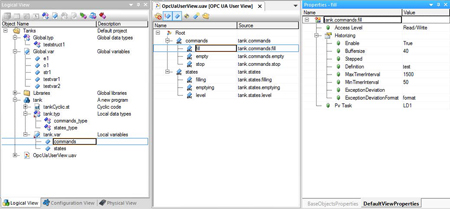

Con OPC UA, se suministra la información necesaria a todas las aplicaciones autorizadas en un cliente desde cualquier servidor configurado en tiempo real en forma de tipos de datos, variables de la CPU (con propiedades), métodos o tareas, independientemente del bus de campo o de otros mecanismos de transferencia utilizados. El estándar utiliza los servicios básicos y los modelos de información para definir cómo se accede a los datos. OPC UA permite una comunicación directa e independiente de la plataforma, entre las diferentes aplicaciones en cualquier hardware y plataformas de sistemas operativos. El entorno de desarrollo Automation Studio es compatible con OPC UA y hace que sea más fácil conectar las soluciones de automatización de B&R a todo tipo de clientes HMI, paquetes SCADA y dispositivos inteligentes. Esto permite a los ingenieros de aplicaciones concentrarse en sus tareas de automatización reales, para que puedan introducir mejores sistemas en el mercado de forma más rápida y eficiente.

El entorno de desarrollo Automation Studio es compatible con los datos de acceso OPC UA y hace que sea más fácil conectar las soluciones de automatización de B&R a todo tipo de clientes HMI, paquetes SCADA y dispositivos inteligentes. Esto permite a los ingenieros de aplicaciones concentrarse en sus tareas de automatización reales, para que puedan introducir mejores sistemas en el mercado de forma más rápida y eficiente.

B&R define la forma en que se intercambian los datos entre los mecanismos de transporte TCP/IP convencionales y los modelos de datos definidos por los fabricantes de dispositivos y las organizaciones de normalización como PLCopen. Lo mismo se aplica en diferentes redes y diferentes empresas a través de Internet y firewalls. “La función de navegación en OPC UA hace que sea más fácil configurar la comunicación industrial entre dispositivos de diferentes fabricantes. Con esta función, los clientes determinan automáticamente qué servidores están disponibles y qué tipo de datos puede aportar cada uno de ellos”, explica Egermeier. El uso de un metamodelo permite evaluar los tipos de datos y la semántica de la información. Esto contribuye sustancialmente a preparar el sistema para el futuro, ya que elimina la necesidad de diseñar una aplicación o sistema operativo para manejar todas las posibilidades futuras del dispositivo servidor.

La complejidad de la aplicación se implementa según sea necesario

El protocolo de comunicación OPC UA, sin duda, va a convertirse en un estándar para las redes de plantas dentro de un corto período de tiempo, debido principalmente a su apertura y facilidad de uso. “Empezar por una vista predeterminada simple y estandarizada simplifica la configuración de aplicaciones con una complejidad limitada”, añade Egermeier. “Si es necesario, las configuraciones se pueden adaptar fácilmente al nivel de complejidad en cuestión usando vistas de usuario orientadas a los requisitos afrontando cualquier limitación”. Tanto en la vista predeterminada simple como en las vistas de usuario individuales, es posible representar cualquier nivel de complejidad a través de pasos de configuración simples.

Con arquitecturas cliente-servidor, OPC UA proporciona mecanismos uniformes, independientes del fabricante para el acceso a los datos y el programa a lo largo de todos los niveles de automatización industrial.