La tecnología de plasma llega al procesamiento de plásticos

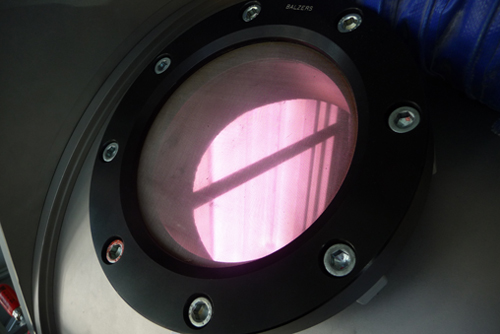

La tecnología de plasma juega un papel pionero en la tecnología moderna de los semiconductores y ha logrado el reconocimiento de otros muchos ámbitos de la alta tecnología. Actualmente los procesos de plasma son cada vez más importantes en el campo del procesamiento de plásticos. Entre las diferentes aplicaciones se incluyen el revestimiento de moldes de compresión y de componentes de máquina, así como el acabado de sustratos de plástico. Sin embargo, por lo general en el desarrollo de los nuevos sistemas de revestimiento se utilizan métodos empíricos y esto significa que a menudo no se dispone de los principios elementales relacionados con la interacción entre los plasmas de alto rendimiento y las superficies técnicas.

Con la ayuda de dos ejemplos de aplicación utilizados en el procesamiento de plásticos, por un lado, el revestimiento de componentes de máquina con antiadhesivo y capas resistentes al desgaste, y por otro, el desarrollo de revestimientos de barrera flexible en termoplásticos, el equipo se esforzará por satisfacer las carencias de conocimientos en la relación entre los parámetros de plasma y las características de los revestimientos, y por utilizar los resultados en controles de proceso basados en el diagnóstico.

El SFB, con una financiación inicial para cuatro años, está dividido en tres campos de investigación. El primero abarca los sistemas de revestimiento en sustratos metálicos para aplicaciones tribológicas (área de proyecto A), el segundo se ocupa de los nuevos revestimientos funcionales con el fin de mejorar el efecto barrera de los sustratos plásticos (área de proyecto B), y el tercero servirá de apoyo para los dos primeros campos aportando estudios sobre los principios elementales de los procesos de plasma (área de proyecto C).

En estrecha cooperación con sus socios, el IKV realizará investigaciones en dos subproyectos dentro del área de proyecto B: la deposición a gran escala de los revestimientos de barrera tolerantes a la deformación sobre películas PET y, basándose en el ejemplo del polipropileno (PP), la influencia de las propiedades de los materiales, por ejemplo, las tensiones internas y las tendencias, sobre el proceso de plasma.

El SFB reunirá a científicos de todos los campos de la física de plasma, tecnología de plasma, procesamiento de plásticos, ciencia de materiales, ingeniería de materiales, ingeniería mecánica y química de interfaces. Todos ellos estudiarán la influencia y el potencial de los plasmas de alto rendimiento, desde el átomo en la fase gaseosa hasta las características de rendimiento de los nuevos sistemas de materiales teóricamente concebidos.

Los institutos participantes en el SFB/TRR 87 son los siguientes:

- Universidad de Ruhr, Bochum (RUB)

- Grupo de Investigación en Plasmas Reactivos (www.reaktiveplasmen.rub.de)

- Instituto de Física Experimental II / Aplicación orientada a la física del plasma (AOP) (www.ruhr-uni-bochum.de/ep2)

- Instituto de Ingeniería Eléctrica y Tecnología de Plasma (www.aept.ruhr-uni-bochum.de)

- Instituto de Ingeniería Eléctrica Teórica (www.tet.rub.de)

- Departamento de Materiales para Microtecnología (www.ruhr-uni-bochum.de/wdm)

- Universidad RWTH de Aquisgrán

- Instituto de Procesamiento de Plásticos (IKV) (www.ikv-aachen.de)

- Instituto de Ingeniería de Superficies (IOT) (www.iot.rwth-aachen.de)

- Química de Materiales (MCh) (www.mch.rwth-aachen.de)

- Universidad de Paderborn

- Ingeniería Química y Química Macromolecular (TMC) (www.chemie.uni-paderborn.de)