Etiquetado en molde con etiquetas barrera de EVOH y recubrimientos tridimensionales

13 de marzo de 2011

Wolfgang Czizegg, director general de Waldorf Technik describe el presente de la compañía del siguiente modo: “Diseñamos y fabricamos equipos para la manipulación de artículos de consumo de la industria médico-técnica, como lentes de contacto; material de laboratorio, como pipetas, recipientes, lapiceras para aplicación de insulina y placas de Petri… prácticamente cualquier pieza de plástico de la que se necesiten grandes cantidades. En la industria del envasado hemos abierto nuevos mercados gracias a soluciones innovadoras de ingeniería y de diseño que permiten reemplazar las latas y los recipientes de vidrio por nuevas soluciones plásticas de precisión”.

En comparación con los materiales de envase rígidos más convencionales y ampliamente aceptados, como los frascos de vidrio y las latas (ambos han sido parte de la vida diaria en todo el mundo durante los últimos 200 años), los plásticos aún son considerados como materiales relativamente nuevos, especialmente por los fabricantes de envases más conservadores. Gracias a los considerables beneficios y ventajas que ofrecen las materias primas plásticas y su producción, el uso de polímeros como una alternativa ingeniosa, duradera y confiable frente a los materiales ‘clásicos’, como el vidrio (frascos y botellas), el metal y otras sustancias (latas), ha llegado para quedarse, especialmente en la industria del envasado de alimentos y el sector médico-técnico.

El uso de plásticos inyectados ofrece infinitas alternativas de envases ingeniosos y de diseño atractivo (diferentes formas, tamaños y espesores), que se pueden adaptar a la perfección a cada producto, sin dejar de lado la atracción de la atención de los consumidores. Además, los envases plásticos son mucho más livianos que los de vidrio y, a diferencia de las latas, su contenido es completamente visible y puede conservarse en el interior de manera segura durante períodos más extensos. Su peso y su volumen resultan beneficiosos en cuanto al transporte y el almacenamiento (debido a la posibilidad de apilar volúmenes mayores), ya que disminuyen las emisiones de carbono y permiten proteger el medio ambiente.

Por otra parte, la seguridad en la manipulación es un aspecto importante: los envases plásticos no producen heridas por roturas, como los de vidrio, o por contacto con los bordes, como en los de lata. Además, prácticamente la mayoría de los plásticos más comunes se pueden reciclar fácilmente. Lo más importante, sin embargo, es que se han hecho y se continúan haciendo grandes avances en la búsqueda de envases plásticos biodegradables para contribuir a resolver el problema generalizado y creciente de la disposición de desechos en todo el mundo.

Tres grandes innovaciones tecnológicas para los envases de barrera

Waldorf Technik hace tiempo que participa activamente en la investigación y la implementación práctica de tecnologías de envasado de vanguardia y ofrece soluciones plásticas de precisión que no sólo beneficiarán a los consumidores sino también a los fabricantes de la industria. De esta forma, no ha permanecido pasivo a la espera de un cambio de actitud en la industria del envasado o a que otros actores sentaran las bases del mercado.

Durante los últimos siete años de intenso desarrollo en este campo en particular, el equipo de investigación de Waldorf Technik ha perfeccionado tres métodos para las soluciones de envases de barrera rígidos y semirrígidos, siguiendo los criterios de innovación, confiabilidad, precisión, alta calidad sistemática, producción a alta velocidad y de grandes volúmenes, eficiencia y, especialmente, un gran respeto por la producción ecológica. Por otra parte, los envases plásticos superan a las soluciones convencionales gracias a su bajo peso y los muy bajos gastos de transporte.

Tecnología I: Etiquetado en molde con etiquetas de barrera

Este proceso, que ofrece principalmente opciones de producción a baja y mediana escala, ya ha sido efectivamente probado, se encuentra en operación y permite la colocación de etiquetas envolventes y en la parte inferior, superponiendo levemente todas las costuras de etiqueta. La etiqueta de barrera está conformada por a) una sección multicapa ultradelgada con Evoh, b) una película de barrera revestida en SIOx o c) una barrera de papel aluminio.

Todos estos componentes ofrecen una solución retortable. Las excelentes propiedades de sellado brindan protección en ambos sentidos contra la migración de vapor de agua o de oxígeno. Hasta el momento, es posible lograr diseños sumamente atractivos y soluciones de diversas formas con un proceso de producción de 8 cavidades o de 2 x 6 cavidades como máximo. De esta manera, es posible envasar de forma aséptica, con frecuencia en salas blancas, una amplia variedad de productos, como sopas, frutas, vegetales, quesos, café, salsas, alimento para bebés, productos para el cuidado corporal, productos medicinales, alimentos para mascotas y otras conservas. El Evoh (etileno-alcohol vinílico) es un copolímero formal de etileno y alcohol vinílico que se utiliza habitualmente en aplicaciones alimenticias.

Tecnología II: Coinyección con PP y EVOH

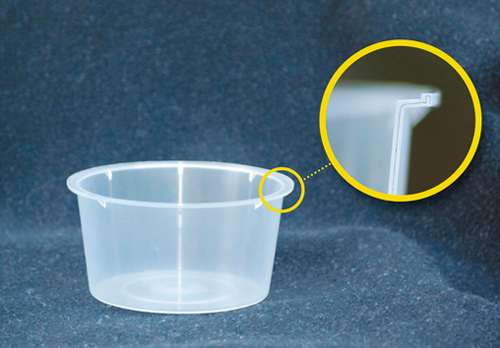

Este proceso de producción, adaptado especialmente a aplicaciones de envasado de alto volumen y, como consecuencia, más orientado al mercado del envasado, se introduce actualmente en el mercado en el que los envases de vidrio y lata son rivales tradicionales. En este caso, la coinyección de estructuras retornables ultradelgadas de 3 capas (PP–Evoh–PP), que incluye un agente de adhesión, permite lograr un proceso repetible que no influye en el tiempo del ciclo al aplicar la barrera en moldes con gran cantidad de cavidades, por ejemplo en una configuración de molde de pisos de 32 ó 64 cavidades. Este es un proceso de inyección que se conoce desde hace años, pero en el pasado no existían pruebas de que la barrera de Evoh se inyectara completa y uniformemente en todo el cuerpo del envase. Sin embargo, este obstáculo ha desaparecido gracias al sistema recientemente desarrollado Check´n Pack Evoh, único en todo el mundo.

Se logra una notable diferencia en el espesor constante y preciso del borde de sellado. Sin embargo, es posible que algunas aplicaciones requieran automatización de la fase de tratamiento secundario, por ejemplo 64 cavidades/6 segundos, para lograr control 100% en línea de toda la capa de Evoh, la extracción 100% en línea de las piezas rechazadas y un proceso y un sistema de logística 100% automatizados. El uso de Evoh en el moldeo por inyección ha sido infrecuente debido a la falta de trazabilidad o métodos de prueba confiables; uno de los factores críticos es que los sistemas de inspección estándar no detectan el Evoh.

El módulo de inspección y visualización de Check’n Pack Evoh permite la inspección en 360º del borde, las paredes, el fondo y el punto de inyección. Este módulo es una marca exclusiva de Waldorf Technik. Además, los niveles de barrera contra el vapor de H2O y O2 son muy elevados y posibilitan (según Kortec Inc., proveedor de la tecnología de moldeo) una vida útil de almacenamiento de hasta 2 años.

De esta manera, se envasan de forma aséptica o con esterilización por autoclave numerosos productos de alto volumen, como pescados, carnes, frutas y alimentos para mascotas. La adopción de esta tecnología generalmente redunda en ahorros de entre 30% y 40% en producción y logística en comparación, por ejemplo, con los gastos del envasado en latas. Además, las formas cónicas, más fáciles de apilar, ofrecen grandes ventajas en cuanto a espacio y peso.

Tecnología III: recubrimiento tridimensional en línea para envases de paredes delgadas

Este proceso consiste en el recubrimiento total al vacío en línea con diversos sustratos de revestimiento Cavonic, que ofrece una opción de gasto sumamente bajo, con una barrera sólida y propiedades herméticas similares a las del vidrio. Una de las principales ventajas es que se puede utilizar en los procesos existentes de inyección, junto con una protección total y segura contra la migración de plastificantes hacia el contenido del recipiente. “Hasta la fecha, los análisis de laboratorio han sido exitosos; es decir, confirman la preparación para el proceso aséptico con el objetivo de lograr una esterilización total. Actualmente, la barrera contra la permeabilidad del oxígeno asciende el 99,15% (130 → 1,1 O2TR) después de la esterilización. Además, la combinación del desempeño de las paredes delgadas, las magníficas propiedades de barrera y los bajos precios de producción convierten a esta tecnología, que puede adaptarse a los polímeros biodegradables, en una propuesta comercial muy atractiva”, concluyó Czizegg.

Gracias a este nivel de especialización e innovación en las tres tecnologías, Waldorf Technik ha alcanzado una posición destacada. “Estas colaboraciones parcialmente exclusivas con Cavonic GmbH, especialista en la técnica de revestimientos de barrera para envases de productos de consumo masivo, o con Kortec, Inc. ofrecen una clara ventaja a nuestros clientes y, posiblemente, revolucionarán el mercado de las conservas”, comenta Czizegg sobre las reacciones de los clientes.

Estas soluciones, combinadas con otras que se encuentran en la fase de proyecto, son la respuesta directa de Waldorf Technik ante la creciente demanda de procesos de fabricación cada vez más seguros, rápidos y productivos con ingeniería de última generación. Con sus 100 empleados, la compañía tiene actividad principalmente en la región central de Europa, Escandinavia, la Unión Europea, Medio Oriente y América del Norte, donde se inauguró una subsidiaria en 2008. La reciente distinción como ‘Compañía Top 100’ reconoce a la empresa por segunda vez por su nivel de innovación entre las medianas empresas de Alemania.