Resultados del proyecto Moldflex de Aimme

Fabricación flexible y personalizada de moldes de resina para la inyección de plástico

30 de diciembre de 2010

Durante este proyecto se ha analizado la fabricación de insertos mediante la técnica de estereolitografía con una resina especial que contiene gran parte de carga de nanopartículas no cristalinas, de alta rigidez, capaz de resistir hasta 260 °C. (Resina NanoTool).

Gracias a la evolución de los materiales desarrollados en los últimos años, se han obtenido resinas de estereolitografía de altas prestaciones cuyas características permiten plantear su utilización como insertos para inyección de plástico.

Durante el desarrollo de los dos años de duración del proyecto se han realizado numerosas actividades para validar la aplicación de estas resinas con experiencias piloto en empresas del sector.

El proceso de estereolitografía consiste en solidificar capa a capa mediante la acción de un láser, resinas sensibles a la luz ultravioleta en estado líquido a partir de un fichero electrónico CAD 3D.

Dado el carácter innovador del proyecto, las primeras etapas se han centrado en la recopilación de información de la experiencia existente en la actualidad en torno a la fabricación de moldes rápidos basados en resina para inyección de plástico así como analizar los requerimientos de un molde obtenido por medios convencionales para la inyección de plástico.

Posteriormente se inició la validación del uso de la tecnología de estereolitografía con resinas cargadas con un molde real. Para la realización de esta actividad se contó con la colaboración de la empresa Matricería Caspe S.L, empresa dedicada al diseño, fabricación de moldes e inyección de piezas.

Se diseñó un molde específico para el proyecto. La pieza a obtener del molde era una pieza sencilla, plana con los logos tanto de Matricería caspe como de Aimme en ambas caras de la pieza. (Figura1).

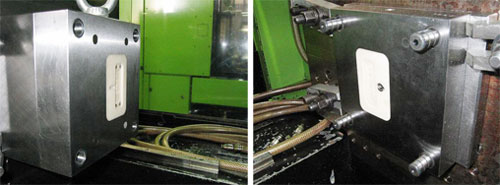

Se diseñó el inserto que posteriormente se fabricaría con la resina NanoTool (Figura 2), tras su fabricación en la máquina de estereolitografía se sometió a un tratamiento térmico para aumentar sus propiedades resistentes.

Los insertos se ajustaron en un molde mecanizado de aluminio (Figura 3).

En estos moldes se inyectó polipropileno, tras unas primeras piezas de ajuste del proceso, se inyectaron aproximadamente 150 piezas correctas. Tras el análisis de los resultados por parte del matricero e inyectador con una experiencia más que comprobada en la fabricación de piezas de plástico, afirmaron que se podría inyectar más de 1.000 piezas sin ningún problema dada las características de los moldes y de la calidad de las piezas obtenidas (Figura 4).

Tras la primera experiencia exitosa, se estableció un plan de experimentos en los que se fabricaron dos insertos más con el mismo diseño de pieza y se comprobó si eran capaces de soportar condiciones más criticas mediante la inyección de un material similar al ABS, poliamida con un 30% de carga de vidrio y poliamida con una poliamida con 10% de carga de vidrio y con un 20% de microesferas. Con estos plásticos reforzados la experiencia no fue satisfactoria.

Como resultado del proyecto es posible concluir que el uso de la tecnología de estereolitografía y en concreto a la fabricación de moldes con resinas cargadas es válido para la inyección de plásticos como polipropileno y polietileno. En el caso de materiales más agresivos será necesario mejorar las características de estos moldes para que soporten las condiciones del proceso de inyección.