Moldes Barcelona, un aliado para el sector del automóvil

2 de diciembre de 2009

Moldes Barcelona abrió sus puertas al equipo de Interempresas TV para mostrar el trabajo que la compañía realiza en sus instalaciones de Polinyà, en la provincia de Barcelona. Así, la directiva de la empresa acompañó al equipo en un recorrido por los distintos departamentos que intervienen en el proceso de fabricación de un molde, en un viaje que se inició en la oficina técnica. En ella, los técnicos de la compañía reciben la información, en la mayoría de los casos, vía Internet y en formato 3D.

Desde la idea original

Según explica Josep Garriga, gerente de Moldes Barcelona, en ocasiones, la empresa recibe el proyecto en 2D, es decir, en un plano, con lo que debe desarrollarlo en volumen (3D) para poder trabajar con él, ya que la mecanización se realiza siempre en 3D. También se da el caso del cliente que define el molde con exactitud, con los parámetros necesarios y el tipo de acero, y que acota las tolerancias. “Entonces nosotros tenemos que fabricar el mejor molde posible dentro de los parámetros que nos pide”, añade Garriga. “Otros clientes no tienen una idea cerrada del molde y nos dan margen para nuestra aportación. Sí saben qué tipo de pieza quieren y tienen claro para lo que tiene que servir, pero el molde en sí no lo tienen definido. Nos dicen con qué máquinas va a trabajar el molde, y con qué proveedor de inyección se piensa producir la pieza. Entonces nosotros debemos desarrollar el molde que dé el mayor rendimiento para la fabricación de la pieza, es decir, el molde que sea más rápido en ciclo, el molde que enfríe más rápidamente, el más adecuado para el volumen de fabricación prevista...”.

Según sostiene Garriga, “no es necesario obtener el mejor molde si el cliente sólo necesita fabricar 5.000 piezas”. Así, si éste es para grandes producciones, debe ser más sofisticado, más elaborado, de más calidad.

Trabajo en época de crisis

¿Cómo en época de crisis puede sobrevivir con solvencia una empresa que trabaja principalmente para el sector de la automoción? Moldes Barcelona no ha sufrido los efectos de esta crisis globalizada. Por el contrario, ha asumido “volúmenes de trabajo enormes” que casi les ha desbordado. ¿Por qué? Garriga responde a la pregunta: “Es difícil de contestar, habría que preguntárselo a nuestros clientes. Suponemos que es debido al esfuerzo y a la dedicación, al intento de ofrecer un buen servicio y voluntad de solucionar los problemas de nuestros clientes”, afirma. “Nosotros no sólo fabricamos moldes. Nos ponemos en la situación de nuestros clientes como si fuésemos nosotros quienes vamos a utilizar el molde. Proporcionamos soluciones que reducir el coste del molde. Perdemos hoy pero ganamos mañana, en el sentido de que el cliente agradece ese gesto y repite”.

Antes de diseñar el molde, se realiza una simulación CAE para elegir el sistema de inyección más adecuado. Con frecuencia, la compañía se encuentra con que la pieza está muy bien diseñada pero con aspectos mejorables en el molde. “Cambiando pequeñas cosas en la pieza, no su función pero sí pequeños detalles (un nervio en una dirección contraria, cambiar un sistema de anclaje...) pueden hacer que el molde, con el mismo costo, dé un mejor rendimiento, sea más sencillo y fácil de mantener, en definitiva, que ofrezca rentabilidad mayor”, afirma el director de Moldes Barcelona.

En la oficina técnica, la empresa dispone de varios programas de diseño técnico. “El diseño en 3D lo hacemos con Unigraphics, Topsolid y Catia. Con ellos hacemos los volúmenes del molde”. A partir de ese diseño, se obtienen las piezas o partes que tras su mecanizado compondrán el molde. Los ficheros se convierten a un sistema universal que puede leer cualquier programa de 3D. Con este fichero el la zona de mecanizados se elaboran los programas en CAM para transmitir la información a las máquinas.

Moldes Barcelona, con la industria del automóvil

En sus inicios, Moldes Barcelona producía moldes para piezas plásticas de interior de vehículos, como difusores de aire. En la actualidad, son capaces de fabricar cualquier molde para cualquier sector, aunque la industria del automóvil representa el 80% de la producción de la empresa. El resto correspondería a envases y manutención y a otros sectores industriales. Hoy en día, la empresa es capaz de diseñar y producir moldes para la inyección y soplado de termoplásticos, así como termoformado, y moldes para zamak o aluminio.

La compañía trabaja principalmente para empresas multinacionales de transformación de plásticos (un 80%, aproximadamente), muchas de ellas con producto propio, pero al servicio de empresas de automoción. Estos moldes acaban fabricando piezas para Porche, Renault, Citröen, Grupo PSA, BMW...”, explica Garriga. El otro 20% son clientes con menos volumen de trabajo “pero que buscan calidad”.

Del diseño en 3D al molde

La oficina de la zona de mecanizado recibe la información en formato 3D, con la que se programan las máquinas, con el dibujo de electrodos para la erosión y toda la información necesaria para el mecanizado de los moldes. El material de los moldes, normalmente de acero de distintas durezas, templados o inoxidables, dependerá de la función de ese molde, del número de unidades a producir, del tipo de pieza a realizar o del material que se vaya a inyectar. Por necesidades técnicas, en determinadas zonas del molde se incorporan piezas fabricadas en latón, cobre o aluminio.

La máquina estrella

De todos los centros de mecanizado de la empresa cuatro de ellos son Awea, una firma de origen taiwanés, representada en España por Juan Martín. “Los hemos ido introduciendo en los últimos años de forma progresiva. Confiamos en la marca gracias al buen funcionamiento de los equipos y a la atención personalizada de Juan Martín, que nos ha ofrecido un servicio excelente desde siempre”. El último modelo, el centro de mecanizado Awea SP 3016, adquirido por la compañía a mediados de noviembre, es la máquina estrella de la compañía. “Nos permitirá hacer moldes de gran tamaño a un precio competitivo. Además, podremos tenerla funcionando de día y de noche”. Para la incorporación de esta máquina de grandes dimensiones, la empresa ha tenido que ampliar sus instalaciones y adquirir una quinta nave, colindante con el resto. Además, ha recibido una subvención de ACC1Ó y del Departamento de Innovación, Universidades y Empresas de la Generalitat de Catalunya, que les ha facilitado créditos blandos para hacer frente a la inversión.

Awea SP 3016: un aliado en la producción

Para la fabricación de los moldes, la empresa cuenta en la actualidad con seis centros de mecanizado de alta velocidad de entre 610 y 3.000 milímetros de recorrido del eje X, cuatro de los cuales son de la firma Awea, distribuida por Juan Martín.

El último equipo adquirido por Moldes Barcelona es un Awea SP 3016, un gran centro de mecanizado de 3.000 milímetros de recorrido del eje X. “Nos hemos decidido por esta máquina por la fiabilidad de la marca. Ya hace muchos años que trabajamos con ella y sabemos que ofrece una baja incidencia en cuanto a reparaciones y una tecnología puntera que evoluciona con gran rapidez”, explica Rubén Pleguezuelos, director de producción de Moldes Barcelona.

La nueva máquina incorpora un programa dentro del control que calcula los pesos de la pieza para mejorar la capacidad de los motores. “Eso confiere mucha versatilidad, porque no es lo mismo mecanizar una pieza que pesa 200 kilos que otra que pesa 8.000. Los motores tienen que graduarse según el peso de la pieza”, afirma Pleguezuelos.

Aunque con ella se puede desbastar, la empresa reserva la máquina para semiacabados y acabados de piezas de figura grandes, normalmente, por sus dimensiones, para el sector de la automoción.

“Pese a tratarse de una máquina de grandes dimensiones, tiene buenas aceleraciones y bastantes revoluciones en el cabezal. Estamos hablando de 10.000 revoluciones con un buen par de motor”, sostiene el director de producción de Moldes Barcelona.

Cuando con las herramientas habituales no se logra acceder a determinadas partes de los moldes, la empresa emplea el mecanizado por electroerosión. Así, fabrica un electrodo, que suele ser de cobre o grafito, que funde el material a través de descargas eléctricas. Para ello, la empresa cuenta con dos equipos de erosión de penetración y dos de hilo.

Ajuste y verificación

El acabado definitivo de los moldes se ubica en una de las naves de la compañía. En ella, se realizan los últimos retoques y el ajuste general de las piezas para la entrega al cliente. “Se comprueban exhaustivamente todos los movimientos de los moldes, y aspectos como la refrigeración. En este departamento, contamos con todos los equipos necesarios para que el producto final se ajuste a la perfección a las exigencias de nuestros clientes”, comenta Torcuato Hernández, director de acabados de la empresa.

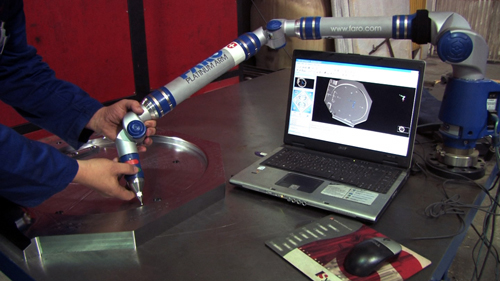

Una vez ajustadas las piezas de los moldes, un brazo robot con una precisión de una centésima por metro realiza una comparativa en 3D entre la pieza final y el 3D original de la misma. “Con esta operación vemos las desviaciones que ha habido en el mecanizado. Si no son tolerables, reparamos el defecto”, explica Pleguezuelos.

Próximos al cliente

La empresa se formó en 1988, fruto de la unión de tres profesionales del sector. “Todos habíamos trabajado en grandes compañías del sector y nos dimos cuenta que en empresas grandes se ofrecía un servicio poco próximo al cliente. Se fabricaban moldes pero sin la complicidad con el cliente que se puede dar en una empresa más pequeña. De ahí surgió la idea de crear Moldes Barcelona. Desde entonces, hemos ido evolucionando y, en la actualidad, contamos con un equipo humano de 22 personas y con todas las máquinas, herramientas e instalaciones necesarias para garantizar un producto final óptimo y ajustado a las necesidades de nuestros clientes”, explica Josep Garriga, gerente de Moldes Barcelona.