Cincinnati Extrusión reduce la zona de enfriamiento a la mitad

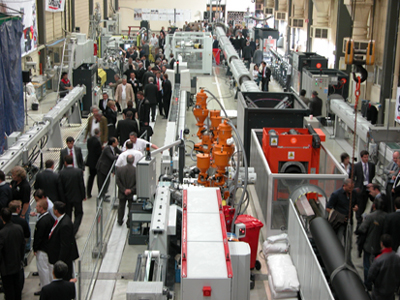

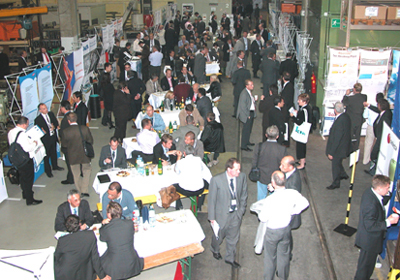

El fabricante de extrusoras austriaco dotó al evento de un componente teórico y práctico. Si por la mañana el centro de atención fueron las conferencias, por la tarde los participantes pudieron ver todas estas soluciones con sus propios ojos en la fábrica de Cincinnati, donde se presentaron seis líneas para tubo en producción. El programa se completó con la exposición en pequeños stands de 25 socios colaboradores, entre los cuales se encontraba la empresa española Molecor.

Reducir la zona de enfriamiento a la mitad

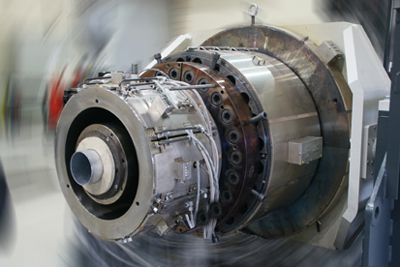

Por primera vez, Cincinnati Extrusion mostró a un público especializado el sistema completamente nuevo KryoSys para la fabricación de tubos de poliolefinas. Permite reducir la zona de enfriamiento en más del 50 por ciento, o duplicar la producción manteniendo la zona de enfriamiento existente. Los visitantes observaron que es posible un rendimiento de más de 1.000 kilogramos por hora en la fabricación de un tubo 400 SDR 11 de PE 100 de Sabic. KryoSys es una combinación del nuevo cabezal con distribuidor de mandril de espiral Iris 40KryoS con enfriamiento de la masa y un enfriamiento especial del interior del tubo. El sistema se presentó en combinación con una extrusora de alta velocidad Rapidex.

La gran ventaja de este cabezal se encuentra en el nuevo sistema para el enfriamiento de la masa fundida dentro de la hilera. Este sistema permite refrigerar la masa fundida en el propio cabezal, de forma que se puede reducir notablemente la longitud de la zona de enfriamiento de la línea. La menor temperatura de la masa fundida tiene como consecuencia una mayor viscosidad en la salida de la hilera, con lo cuál se actúa también contra el efecto de descolgamiento, especialmente cuando se trata de tubos con paredes gruesas.

En otras dos líneas, Cincinnati mostró la fabricación de tubo de PEX-a para agua caliente y tubos de calefacción a distancia y el cambio rápido de dimensión en la fabricación de tubos de poliolefinas. Ambas líneas también habían sido desarrolladas en cooperación con socios colaboradores.

La línea para tubos desarrollada junto con LK-Pex, de mayor rendimiento en la fabricación de tubo de PEX-a que una con extrusora de pistón, logró un rendimiento de hasta 120 kilogramos/hora fabricando un tubo de 63 milímetros, utilizando una extrusora cónica de doble husillo Konos 63 con cabezal especial. El material procesado era un tipo de PEX de Borealis, que se reticuló de forma peroxídica con la ayuda de un horno horizontal de infrarrojos.

Un millón de kilómetros de tubo al año

“A lo largo de los próximos cuarenta años se instalarán anualmente un millón de kilómetros de tubo”. Así lo estimó en su conferencia de apertura el Profesor Kroiss, del Institut für Wassergüte en la Universidad Técnica de Viena. Con esta estimación coincidieron también el resto de las presentaciones. Los tubos se seguirán necesitando en todo el mundo, principalmente para redes de suministro y desagüe de aguas, pero también para la conducción de gas y como tubos de protección, porque es razonable recurrir a ellos tanto desde un punto de vista ecológico como económico. Las actuales tendencias indican que en el futuro serán necesarios aún más tipos diferentes de tubos de diámetros pequeños y grandes. Esta necesidad requiere lógicamente nuevas inversiones y es por ello que las perspectivas de futuro son positivas. Las exigencias a las que se verán sometidos los fabricantes de máquinas, según dijeron los conferenciantes, son un mayor grado de automatización, una mayor flexibilidad y una mayor gama.

Dos procesos para tubos de aluminio y plástico

Otra atracción muy llamativa para los asistentes fueron las dos formas diferentes que se presentaron para fabricar tubo compuesto de aluminio-plástico de cinco capas. Los tubos compuestos de aluminio se utilizan principalmente para calefacción radial (bajo suelo) por sus ventajas, ya que, debido a la capa de aluminio, son fáciles de instalar, a lo cual se une la ausencia de incrustaciones y de corrosión que proporciona el plástico.

Una de estas dos líneas completas se ha desarrollado en colaboración con Nexans. Incluye un total de cuatro extrusoras, dos Talos 60-30 G con husillo optimizado para PEX y dos coextrusoras, y está pensada para aplicaciones de alto rendimiento. En la fabricación de tubo de 16 mm de PEX-b de Solvay Pedanaplast con 2 mm de espesor de pared, alcanzó una velocidad de 40 m/min. En este caso se recurrió a la técnica de soldadura a tope TIG.

Al contrario que ésta, la otra línea presentada es ideal para los recién llegados a este sector que quieren participar en el creciente mercado de los tubos compuestos de aluminio. Esta línea concebida con Maintools es segura, fácil de operar, relativamente corta y recurre al método de soldadura de ultrasonidos por solapamiento para la capa de aluminio. Con la misma dimensión de tubo y con dos extrusoras monohusillo Talos 45-30 G para la capa interna y externa de PE-RT de Dow Chemical, así como dos coextrusoras para las capas intermedias de adhesivo, alcanzó un rendimiento de 25 metros por minuto.

También en colaboración con Maintools, el fabricante de extrusoras mostró una solución económica para la fabricación de sistemas de regadío en un proceso de doble vía. La banda para regadío producida, que se realizó en una línea con un rendimiento de 60 kilogramos por hora y una velocidad de 40 metros por minuto, disponía de un canal “aplanado“, que tan solo vierte a las plantas 250 mililitros de agua por cada metro, cada diez minutos. Se utilizó para ello una extrusora Talos 60-30G y el material era un PP de Sabic.

Finalmente, también destacó el sistema de cambio rápido de dimensiones realizable durante el proceso de extrusión del tubo. Con el sistema IntelliChange, desarrollado con componentes de la empresa Inoex, se ofrece a los transformadores una solución económica, que permite una reacción rápida ante las exigencias del cliente, reduciendo así los costes y las necesidades de almacenamiento.

Se presentó con la fabricación de un tubo de dos capas de PE, con cambio de diámetro entre 63 y 160 milímetros. Para la plastificación del PE 100 de Borealis se recurrió a una Talos 75-30G. En combinación con la coextrusora Alpha 45-30G se alcanzó una capacidad de producción de 300 kilogramos por hora.