BASF Develops pieces semiacabadas of composite for the car sector

5 March 2014

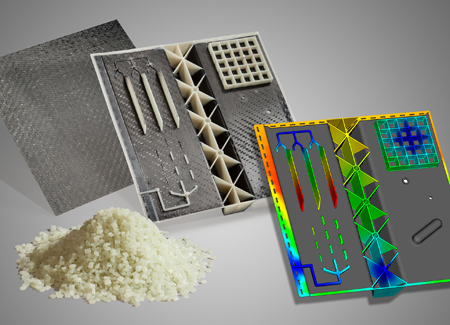

The second component of the package Ultracom are the materials for on moldeo, that have developed specifically to use with the materials laminados. These materials also proceed of the lines of product Ultramid and Ultradur, this time in shape of compound materials. Thanks to the combination of materials laminados and stravel can produce complex pieces by injection, with mechanical reinforcements very high in locations very clear-cut and precise, by means of the utilisation of continuous fibres, and that at the same time integrate several specific functions like result of the on moldeo.

BASF Will offer already his first commercial package of product Ultracom. For those customers whose projects require pieces with high rigidity, this package includes Ultralaminate with base of polyamide 6 (or Ultratape if they need reinforcements highly addressed) combined with Ultramid G12 COM, that has a 60 percent of reinforcement of fibre of glass like component of on moldeo. For applications subjected to crash that require a special resistance to the impacts, BASF offers a package that has optimised to present a high absorption of power. This package includes Ultralaminate and Ultramid ZG7 COM. In this case it exists a version in strip, Ultratape, for the reinforcement located, as the one who requires for example in the structures of the seats. It can on moldear with the same Ultramid ZG7 COM. For now the family of structure ortotrópica Twill-2/2, from textile materials technicians and polyamide 6, will use for the materials laminados. The first pieces of pre-production realizar with Ultracom will exhibit in K-Show 2013.

This third component of the package Ultracom, the support of engineering, is not simply an option that can use when it was necessary, as it was the case in projects of low previous weight: it Is an essential component of all the projects of the customers. Without the capacity to optimise the design and the production, and the capacity to describe numerically the behaviour of the materials composites and the pieces by means of the integrated simulation, as in the case of the thermoplastic with reinforcement of short and long fibre traditional, would be difficult to reach a successful launching to scale of market. During the last years, the tool of simulation Ultrasim® of BASF has attained to develop and design a lot of new pieces, like the transversal beams of transmission, the bancadas of engine and frontends without metallic reinforcements. The pieces of composite thermoplastic with base laminado or strip will be a viable solution for the production on a large scale, only if it complements the integrated simulation with new models of material and experimental discoveries that the sustenten. The first application of production of Ultramid based in laminados of on moldeo produced (and follows producing) externamente, in 2012, in shape of base for the seat of the Opel Astra OPC. For this application, already was possible to use the properties expanded of Ultrasim. Now already they are available for all the customers in the context of projects of conjoint development.