Desarrollo de elastómeros termoplásticos - TPE con características innovadoras

Hasta ahora, el cromado de piezas plásticas realizadas con materiales duros y elastómeros solo podía realizarse a través de un proceso costoso y tecnológicamente exigente que constaba de varias etapas. Los nuevos compounds de TPE Allruna que resisten los baños de cromado sin metalizarse, ofrecen libertades anteriormente irrealizables para el diseño de piezas, además de claros ahorros de costes de proceso.

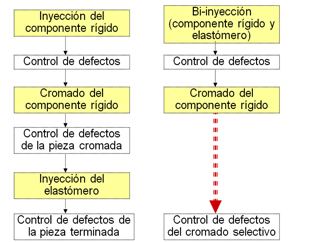

Las superficies de plástico cromadas tienen gran aceptación en el mercado debido a su gran calidad óptica y a la agradable sensación táctil. Piezas de plástico con estos acabados pueden encontrarse en numerosos sectores y aplicaciones. Hasta ahora, el cromado selectivo de piezas compuestas por uniones de materiales duros / blandos se realizaba a través de un proceso costoso y tecnológicamente muy exigente que implicaba múltiples etapas. Los pasos individuales del proceso se ilustran en la Figura 1.

Una vez que el componente duro ha sido moldeado por inyección, es metalizado. A continuación se coloca la pieza ya cromada nuevamente en el molde de inyección para realizar la inyección del material blando. Este proceso implica varias complicaciones debido a que los tipos comunes de elastómeros termoplásticos - TPE no se adhieren a las superficies metalizadas.

Problema y objetivos

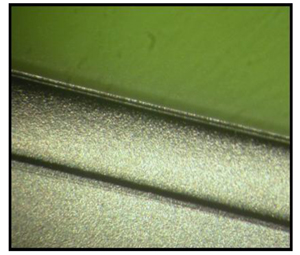

El cromado en un solo paso de piezas compuestas por materiales duros y blandos era hasta el día de hoy un proceso difícil de realizar por varias razones. Por un lado, el componente blando es severamente dañado por el baño galvánico y se muestra la falta de líneas nítidas en la zona de transición del componente duro a blando. Igualmente esta zona se ve afectada por la formación de halos y/o de un crecimiento excesivo del metalizado (Figuras 2 y 3).

Por otra parte, los baños galvánicos son dañados por compuestos disueltos desde los materiales blandos asimismo se observa que el componente blando absorbe sustancias del baño de galvanizado que a posteriori migran.

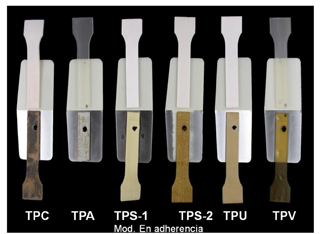

La figura 4 muestra unas placas de ensayo de elastómeros termoplásticos comerciales, en combinación con ABS / PC, que han sido sometidos a un proceso clásico de cromado. Todos los TPE independientemente de la base química desarrollaron una clara decoloración. En los tipos de base de poliéster (TPC) se observó en la superficie huellas de “carbonización”. En uno de los tipos de TPS (base estirénica) es visible la formación de un halo.

La principal desventaja de la solución actual es, ante todo, su alto costo, ya que varias tareas sólo pueden llevarse a cabo manualmente. Además, este proceso impone exigencias muy elevadas en los moldes, así como en los pasos individuales del proceso necesarios para evitar los altos costos por mermas. Esto requiere un dispendioso retoque de los moldes y el uso de al menos tres diferentes plásticos, a fin de asegurar la fiabilidad del proceso. Lo que resulta en altos costos de inversión, así como altos riesgos de error durante la secuencia de procesamiento

Por lo tanto, el objetivo de este proyecto fue desarrollar un nuevo material elastómerico para la técnica de cromado selectivo. De forma que se pueda realizar inicialmente una inyección multi-componente de las uniones duro/blando y a continuación cromar de manera selectiva la pieza completa. Este método debe permitir una estabilización de este proceso, la reducción del tiempo de fabricación y una reducción substancial en la tasa de rechazos del cromado de las uniones de materiales duros-blandos. Igualmente, se debe evitar el ataque ácido en el TPE durante el proceso de decapado. El revestimiento metalizado debe abarcar solamente el componente duro y terminar claramente con líneas definidas en la zona de transición del TPE.

Modificación del elastómero termoplástico (TPE)

En primer lugar se investigó la resistencia química de diversos tipos comerciales de TPE en diversos baños galvánicos (Fig. 4). Posteriormente a estas piezas se les realizó pruebas de envejecimiento en un horno de calentamiento para establecer en qué medida la estructura macromolecular de los materiales blandos había sido dañada.

Basándose en esta información, se realizaron las modificaciones correspondientes a los materiales elastoméricos y se adaptaron para el proceso de galvanoplastia. Utilizando combinaciones de diferentes materiales y procesos, se examinó la procesabilidad y la aplicabilidad a gran escala para piezas fabricadas actualmente en serie.

Criterios de evaluación

Las piezas que fueron inyectadas con materiales duros y blandos y posteriormente cromadas fueron examinadas acorde a unos criterios de evaluación definidos:

Se realizó una prueba visual del componente blando que constaba de un examen general de la pieza, así como un análisis de la condición de la superficie. Luego del proceso de cromado se realizaron ensayos del comportamiento de los componentes blandos bajo esfuerzo. Igualmente, se evaluó el acabado metálico del componente duro, siendo de gran importancia la definición de la zona de transición entre los componentes duro y blando (Fig. 5).

Después del proceso de metalizado, la pieza completa fue sometida a un ensayo de envejecimiento térmico (125 °C/96 h) y se evaluó visualmente el daño.

Con el fin de establecer cualquier cambio en la fuerza de adhesión, se hicieron pruebas de adherencia entre el material termoplástico y el TPE en función de la trayectoria de flujo, antes y después del cromado.

Para permitir que el material se utilice en las aplicaciones de cuidado personal y cosmética, fueron significativas la prueba de inocuidad toxicológica, así como los análisis de resistencia a medios de contacto. Estos análisis también incluyeron la comprobación de residuos de cromo en el material blando.

Así mismo, se evaluó la solidez del color en el material después del proceso de galvanoplastia, a fin de evitar la decoloración después del proceso.

Fig. 5. Líneas nítidas en la zona de transición del material duro (ABS/PC) y el elastómero ALLRUNA.

Conclusión

El proceso de investigación indica que ahora es posible producir piezas de compuestos metalizados duros-blandos mediante moldeo por inyección multi-componente y su posterior cromado. Dado que el proceso es significativamente más corto en comparación con el estado actual de la tecnología, resulta un gran potencial de ahorro en términos de costos de moldes y fabricación, así como en logística (ver fig. 1). Los requerimientos de trabajo y el riesgo de error se reducen considerablemente, de modo que las mermas del proceso de cromado podrían reducirse a <3%. Otras ventajas adicionales a la reducción de costes se derivan de la posibilidad de integrar funciones, tales como interruptores de membrana.

Este método mejorado puede dar acceso a nuevas áreas de aplicación en una amplia variedad de campos. La posibilidad del uso de estos nuevos elastómeros termoplásticos ofrece un amplia gama de aplicaciones desde revestimientos para cromado hasta la libertad para nuevos diseños, p.e. efectos especiales de luz a través del uso de elastómeros transparentes; posibles efectos de profundidad, decoración, estampados y nuevas configuraciones de colores…

El cromado selectivo se ha convertido en una opción económicamente viable frente a otras alternativas de recubrimientos metálicos como el lacado, ofreciendo terminaciones de gran calidad y ventajas adicionales de diseño.

Autores

Procter & Gamble AG, Kronberg, Alemania:

- Gerald Görich, Director del area de procesamiento de plásticos

- Sebastian Graf, Ingeniero de proceso

- Carolin Zobl, Ingeniera de proceso

Allod Werkstoff GmbH & Co. KG, Burgbernheim, Alemania:

- Alexander Näck, Ingeniero de proceso

- Viviana Avendaño, Representante de Allod en España.

Para más información sobre esta nueva gama de TPEs para cromado selectivo y sus actuales aplicaciones contactar a viviana.avendano@allod.com