El camino de la tecnología verde marca la presencia de battenfeld-cincinatti en la K

“Con nuestra presencia de este año en la feria, subrayamos la importancia de la iniciativa BlueCompetence de la asociación VDMA, de la que formamos parte como empresa asociada, y presentamos nuestras solciones para la extrusión de alto rendimiento que hacen posible un trabajo responsable con los recursos disponibles” afirmaba el CEO de la compañía, Jürgen Arnold, al presentar el lema de battenfeld-cincinnati, representado en España por Comercial Douma, en la K 2013: ‘Leading solutions for high performance & energy efficiency’.

“La unión de ambas empresas y la consecuente unificación de los productos y de los conceptos de procesos y TI se ha realizado con éxito y con eficacia. Es por ello que la gama de productos tiene menos de tres años y, dado que las dos empresas ya centraban su atención desde mediados de la década de los 2000 en la eficiencia energética y el aprovechamiento de los recursos, las máquinas de hoy en día están totalmente actualizadas al nivel de la técnica actual en lo referente al consumo de energía, de agua y de ahorro de material. Es por ello que nuestras extrusoras y líneas de extrusión se ajustan a la iniciativa de sostenibilidad de la asociación VDMA”, señala Arnold, y da un paso más: “battenfeld-cincinnati ha involucrado en los procesos a sus proveedores y también ha mejorado los consumos de energía y de material de sus sedes. Con nuestras líneas de extrusión ofrecemos la plataforma para una producción que cuida los recursos y la correspondiente capacidad para competir de nuestros clientes”.

Estas afirmaciones se ponen de manifiesto en la presentación de soluciones de extrusión de las tres divisiones de battenfeld-cincinnati, es decir, Construction, Infrastructure y Packaging, que operan de forma eficiente energéticamente hablando y ahorrando material y que, precisamente por ello, aportan a cada sector la mejor relación coste/beneficio.

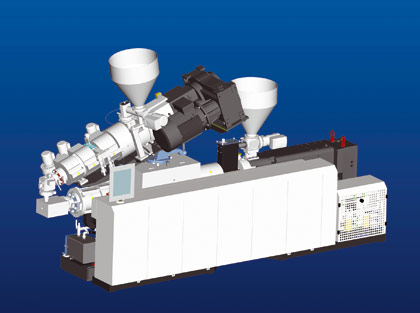

Construction: Extrusoras superpuestas para ahorrar algo más que espacio

Lo más destacado de la División Construction es este año la solución de dos extrusoras superpuestas, la twinEX 78-34 P paralela y la conEX 63 P cónica. Con esta configuración compacta de las máquinas el fabricante responde a la tendencia del sector de los perfiles para ventanas que apunta a un mayor uso de material reciclado. Por motivos económicos y ecológicos, hoy en día se utiliza hasta un 40% de material reciclado en la fabricación de las zonas no visibles de los perfiles principales para ventanas. La combinación de máquinas que se presenta está configurada para lograr una capacidad de producción de hasta 500 kg/h. Ambas extrusoras, como todas las de la marca battenfeld-cincinnati, están equipadas con motores AC, así como con regulación de temperatura Intracool del núcleo del husillo, y cilindro totalmente aislado con enfriamiento inteligente por aire. La solución de máquinas superpuestas es la respuesta a la exigencia de la iniciativa BlueCompetence en relación con el ahorro de material.

Infrastructure: Menos consumo de energía sin transmisión

Packaging: alto rendimiento, con un bajo consumo de energía

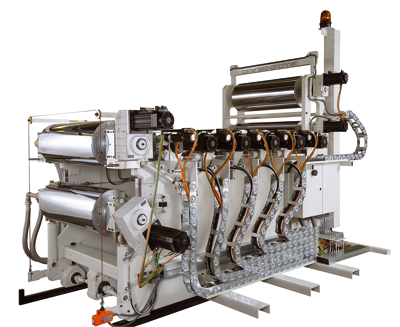

Con la calandra Multi-Touch battenfeld-cincinnati presenta una novedad que opera cuidando bien el material y el consumo de energía. Gracias a una combinación especial de una calandra de dos rodillos para el precalibrado y de un mayor número de rodillos para el postcalibrado, con esta calandra se pueden fabricar a alta velocidad películas sin tensiones con una precisión del 1%. Mediante la incorporación de rodillos de paredes delgadas Multi-Touch presenta una eficiencia energética especial.