Nuevos sistemas de decoración de miniaturas de juguete mediante tampografía

Sin embargo, existen ciertos inconvenientes derivados del uso de etiquetas adhesivas, como son el empleo de mano de obra para el pegado de éstas y la baja durabilidad sobres sustratos blandos. Pero sobre todo el elevado coste de troqueles, películas, diseños, etc. que hacen que para que sea rentable, se deban incluir en una misma lámina muchas adhesivas y para distintos modelos. Esto limita a su vez los cambios en el diseño de las miniaturas y en la impresión de las adhesivas impidiendo una renovación continua de los productos.

La decoración mediante tampografía de vehículos de juguete en miniatura no se está empleando en la actualidad debido a que estos sistemas de decoración no permiten la fácil adaptación a productos con geometrías complejas, como superficies curvas e irregulares. Sin embargo mediante este sistema se consiguen velocidades de producción más elevadas, cambios más rápidos y la capacidad de imprimir con más colores.

La empresa Guisval, junto con el apoyo del centro tecnológico Aiju, ha desarrollado un proyecto de I+D cuyo objetivo principal es el desarrollo y optimización del proceso de decoración de juguetes en miniatura de geometría irregulares mediante la técnica de tampografía con costes similares a los actuales, sustituyendo de este modo el uso de etiquetas adhesivas.

Los objetivos técnicos específicos perseguidos inicialmente eran principalmente tres: Desarrollo de accesorios y complementos específicos y otras modificaciones en el sistema de tampografía estudiando diversas formas de adaptar productos con geometrías irregulares al equipo. Optimización de la adhesión pintura-sustrato para cada tipo de tinta y combinaciones y para cada tipo de figura y material. Optimización del proceso de decoración en cuanto a automatización y flexibilización. Validación técnica y económica.

Como resultado, Guisval ha conseguido ser la primera empresa española y mundial que ha puesto en el mercado motos en miniatura decoradas mediante tampografía.

Desarrollo y resultados

Las actividades realizadas se resumen a continuación:

En primer lugar se llevó a cabo una revisión del estado del arte en decoración mediante tampografía así como de los complementos y articulaciones adaptables que existen con el fin de investigar las últimas novedades existentes y seleccionar, de entre ellas, los elementos más apropiados para automatizar el proceso, adaptándolo a todo tipo de piezas y el posicionamiento de las piezas en sus distintas ubicaciones.

Una búsqueda de patentes de los últimos 10 años demuestra que se ha innovado en los siguientes aspectos relativos a la obtuvo decoración mediante tampografía: Optimización del proceso de impresión de objetos esféricos. Aplicación del proceso a productos novedosos como lentes de contacto, partes de vehículos, prendas de vestir, ribetes de calzado, caramelos, etc. Procedimiento mediante una lámina de transferencia. Nuevas máquinas impresoras que facilitan el proceso de la plancha de impresión y hacen el proceso global más económico. Nuevos procesos que incluyen conceptos mixtos (sublimación- tampografía).

Además se realizó una búsqueda en publicaciones y revistas de referencia en la que se observó en este caso la potencial aplicabilidad que esta técnica tiene en la realización de células solares, la impresión de textiles utilizando tintas reactivas, la generación de electrodos desechables y en etiquetas RFID. Adicionalmente, se estudian parámetros como la deformación del tampón de caucho y sistemas de posicionado del cliché. Los tampones se ven sometidos a grandes deformaciones durante el proceso, por lo que la fuerza de impresión debe regularse con la finalidad de obtener una buena impresión sin comprometer la definición de la imagen. Tanto la dureza como la fricción afectan a la distorsión del tampón y, por lo tanto, las dimensiones de las imágenes que son críticas en aplicaciones tales como miniaturas para coleccionistas y/o promoción.

Los desarrollos futuros de la técnica van destinados a la generación de máquinas que incluyan más funciones como limpieza de tampones automática, control integrado de la viscosidad (adición de diluyente), control electrónico de todas las funciones, selección y optimización de sistema de tinta abierto o cerrado, aptitud para acoplar accesorios especiales, independientemente del grado de complejidad, lo cual va en línea con el desarrollo realizado en la empresa.

En cuanto a las especificaciones de las piezas a decorar seleccionadas para el proyecto, se realizó una evaluación para determinar las características comunes que reúnen las piezas a decorar y las distintas tonalidades de color. De este modo, se han definido:

- las características, tamaños y geometrías de las piezas a decorar y su ángulo de posicionamiento

- las zonas, áreas y geometrías de los artículos más habituales objeto de decoración

- el motivo decorativo más común en función del artículo y las zonas a decorar

- el tipo de sustrato y el mejor método para optimizar la adhesión de las pinturas

- los colores a emplear, matices y combinaciones

- las tintas en función del material plástico de la moto

Los productos de Guisval son muy variados en formas y tamaños. Por ello, tras una clasificación según los criterios anteriores se seleccionaron finalmente los artículos: Motos de competición y Motocross y Camión de reparto, debido a las geometrías complejas que presentan y que suponen un reto para su decoración por tampografía. Se trata de vehículos a escalas 1:29 y 1:22 en las que hay que decorar el carenado, donde actualmente llevan las adhesivas en el caso de las motos así como a los camiones cisterna con geometría redondeada. Los motivos decorativos son variados (colores, números, banderas, marcas y promoción, etc.) siendo en el caso de las motos imitación a motocicletas reales de competición, con lo que se emplean colores corporativos de los patrocinadores, formas idénticas, etc. puesto que son reproducciones fieles. En función del nivel de detalle, el público objetivo de estos vehículos son los coleccionistas o el público infantil.

Se ha trabajado entonces en el desarrollo y mejora de los equipos de tampografía dentro de los siguientes aspectos críticos:

- El posicionamiento y colocación de la pieza de forma automática y, en consecuencia, el sistema de sujeción. Al tratarse de piezas tan pequeñas el más mínimo desplazamiento puede producir unos errores de impresión considerables (un movimiento de 0,5 mm por ejemplo conduce a un fallo en la impresión de enormes proporciones). Por ello, desde el inicio el objetivo del proyecto se ha centrado automatizar y sistematizarla sujeción y posicionamiento de las distintas piezas de forma precisa. Se han desarrollado para ello soportes tanto personalizados como versátiles con el fin de realizar una comprobación previa de la correcta colocación de la moto y evitar así desplazamientos y vaivenes no deseados que altere la precisión de la decoración, tal como se aprecia en la Figura siguiente.

- Unido a la obtención de nuevos útiles y complementos para el correcto posicionamiento de las piezas se encuentra el diseño de los diferentes motivos de decoración para ajustarla posteriormente a las superficies a decorar, para generar los fotolitos para tampografía, desarrollo que se realiza también en la empresa.

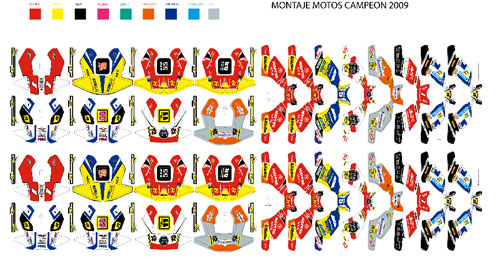

- En lo referente a la coloración aplicable, puede observarse que existe una alta diversidad de tonalidades que, en muchos casos, es muy específica. Como ejemplo se incluye en la Figura 4 una fotografía de la lámina de etiquetas adhesivas empleadas hasta el momento en la que se aprecian todas las zonas a cubrir por la decoración y los colores necesarios para uno de los tipos de motocicleta, y que se ha sustituido finalmente por tampografía, apreciándose la complejidad del producto. Por ello, se ha desarrollado una sistemática de creación y ajuste de los diseños a las zonas a tampografiar y obtención de coloraciones.

- Los tampones obtienen el motivo decorativo del cliché y lo imprime sobre el sustrato a decorar. Su producción se realiza en una variedad sin fin de formas, dureza y tamaño. Se ha realizado un estudio con la finalidad de valorar las diversas formas y durezas de tampones existentes para cada tipo de geometría y coloración buscada. Por ejemplo tampones con forma angular proporcionaban mayor versatilidad y adaptación a las geometrías irregulares. Tampones con mayor dureza pueden transferir muy bien la imagen y tiene una mayor duración debido a su alta consistencia mecánica, sin embargo sobre una superficie muy curvada, debe utilizarse un tampón más flexible ya que éste puede adaptarse más fácilmente a ésta.

- Otro de los objetivos de este proyecto era la adaptación de secadores complementarios con el objetivo de acelerar el proceso de secado de las piezas y, así, incrementar la productividad, realizando una valoración de eficiencia energética.

- Junto con el centro tecnológico Aiju se trabajó en el desarrollo de un proceso sistemático para la obtención de nuevas coloraciones. Para ello se realizó en primer lugar un estudio de las propiedades de adhesión de los distintos sustratos plásticos que pueden ser empleados para la fabricación de las partes plásticas de las motos y camiones, a priori ABS, PP y PE. Se ha considerado la aplicación de tratamiento superficial mediante plasma de baja presión para mejorar la adhesión de la pintura. Con este estudio se ha determinado el material que mejor adhesión con las pinturas de tampografía proporciona antes de inyectar las piezas finales.

Se realizó posteriormente una caracterización de distintas tintas de tampografía, para definir las más adecuadas para el sustrato plástico seleccionado.

- Una vez realizadas las acciones previas para la adaptación e integración de los complementos desarrollados, se tuvo que automatizar este proceso en alta velocidad para conseguir una producción ininterrumpida y, a su vez, lograr la maximización del proceso con el fin de ahorrar en costes de fabricación.

- Por último, y con piezas ya inyectadas con geometrías irregulares se han realizado numerosas pruebas de impresión evaluando el correcto pintado, la suficiente adhesión inicial de la pintura al sustrato, potenciales modificaciones adicionales del equipo y la eficiencia del proceso.

Conclusiones

Con las tareas realizadas se ha conseguido desarrollar un salto tecnológico en estos desarrollos dirigido a la mejora significativa en: automatización del proceso, desarrollo de herramientas y accesorios, siendo especialmente relevantes los soportes tanto personalizados como versátiles para el agarre y posicionamiento de la pieza, desarrollo de un proceso para obtener el diseño de las decoraciones de forma directa para la tampografía, así como coloraciones novedosas y optimización del proceso y materiales para no incrementar el coste de producción.

Agradecimientos

La empresa agradece al CDTI el soporte financiero del presente proyecto (Ref. IDI-20120149).