Moldes más rápidos y económicos con KnowEDM

Todo esto se conseguirá desarrollando el conocimiento basado en la tecnología automatizada EDM (Electro-Erosión), que se integrará en los utillajes y en la fabricación de componentes de alta precisión. Dicho proyecto se verá beneficiado de la puesta en común del acopio de conocimiento, experiencia y esfuerzo por parte del consorcio de los 20 miembros, complementado por las aportaciones de las empresas asociadas. Esto asegurará que tanto el programa de trabajo como sus beneficios estarán mejor confeccionados para las empresas a las que se dirige este proyecto.

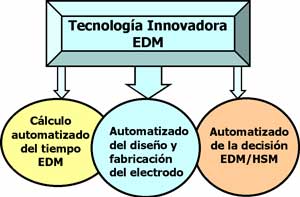

Dentro del proyecto KnowEDM se desarrollarán tres módulos, cada uno con un propósito específico:

- Tiempo estimado del funcionamiento de la electro-erosión;

- Automatización del diseño y fabricación del electrodo;

- Automatización de la distribución optimizada dentro del funcionamiento mecánico entre el mecanizado de alta velocidad y la erosión, en criterios de coste y tiempo.

Objetivos principales del proyecto KnowEDM:

- Reducción de hasta un 50 por ciento del tiempo requerido en el diseño y fabricación de los electrodos.

- Reducción en tiempos de producción por medio de la decisión optimizada entre mecanizado en alta velocidad y electro-erosión.

- Estimación precisa de tiempos con EDM.

- Mejora de integración en la cadena desde el diseño del producto hasta la producción e inyección del molde.

El proyecto KnowEDM está siendo llevado a cabo por el Programa de Investigación Colectiva de la Unión Europea, del cual los representantes de los Centros Tecnológicos asumen las actividades de investigación tanto científicas como tecnológicas en nombre de las asociaciones industriales y de sus empresas miembro, con el apoyo y participación de varias pymes en cada país. Este esquema de financiación de I+D está destinado a ayudar a las empresas europeas a mejorar su competitividad.