Matrix desarrolla el primer molde trimateria para el sector del packaging

Para poder conseguir el objetivo más ambicioso del cliente, que era el de inyectar el producto completo con una sola máquina, se ha tenido que instalar en esta maquina una cuarta unidad de inyección y poder ensayar la inyección de una cuarta pieza dentro del molde trimateria.

El departamento de ingeniería de Matrix ha trabajado varios meses para poder desarrollar toda la tecnología del molde, en la cual se han aplicado ideas que están en proceso de ser patentadas.

El objetivo inicial marcado por el cliente, se ha conseguido mejorar en un 10 por ciento, gracias a un novedoso sistema de giro. Este sistema permite absorber las inercias provocadas por la rotación a gran velocidad de partes del molde y frenarla en el último instante, sin emplear elementos mecánicos ni micros de posición. El molde dispone de cuatro cámaras calientes con boquillas de inyección lateral e inyección con válvula, diseñadas y construidas íntegramente en Matrix.

Estas nuevas aplicaciones abren un nuevo campo de enormes posibilidades dentro del sector del packaging, ya que permiten desarrollar piezas que pueden ser unidas o montadas dentro del molde.

La dirección de Matrix cree que el futuro pasará por tener unidades productivas en donde el molde jugará un papel muy importante, porque deberá inyectar varias piezas y unirlas con inyección o montarlas dentro del molde. Esta tecnología necesita máquinas de inyección con varios husillos y con una gran flexibilidad. Los métodos tradicionales requieren un molde y una máquina para cada elemento, además de la máquina de montaje para ensamblarlos. Esto ha supuesto siempre una gran inversión en máquinas y espacio, con lo que el coste del producto acabado es muy alto.

Con este nuevo desarrollo Matrix da un nuevo paso para consolidarse como moldista líder dentro del sector y que tuvo su inicio al abrir la nueva planta de Ripoll en el año 2003.

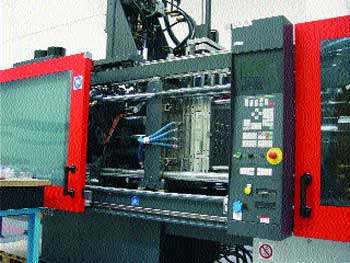

La estrategia de Matrix ha sido siempre la de dar a sus clientes un servicio completo, colaborando desde el primer momento en el diseño del producto, hasta la fase de homologación del mismo en sus propias instalaciones. Con este objetivo, se potenció el Centro Tecnológico con una máquina Husky de 400 toneladas, a la que se le instaló una unidad vertical de inyección Windsor para realizar la puesta a punto de moldes de bi-inyección y una nueva máquina Ferromatik de 155 toneladas con 3 husillos para proyectos de I+D.

En febrero de 2004, Plásticos Universales (número 91) publicó un extenso reportaje sobre la empresa Matrix.