Development of new high mechanical performance resins-based SCM epoxy and vinylester

Head of the line of Termoestables materials of Gaiker technology centre

01/11/2005- Pieces for the naval sector: must present adequate mechanical performance, supported by the lightness in its composition and good surface finish, etc.

- Those intended for the coatings industry: must present excellent properties of surface appearance, as well as appropriate properties to abrasion.

- To sectors of high mechanical performance (wind, safety apparel, construction): must present excellent mechanical properties, usually to impact, bending and compression.

- For the sector of abrasives: must present an adequate abrasion resistance and stiffness or resistance interlaminar (high speed turn) operating conditions.

- Those designed for the electricity sector. The properties of plastics composites such as Electrical insulators, mechanical resistance, its high resistance to heat, moisture and durability make them the material suitable for this type of applications.

The materials used in the manufacture of the sheet have been of different types of matrices; epoxy, vinylester-epoxy (resins latest generation) and vinilésteres common, additives of formulation (stiffener agents, Assistant process, etc) and various reinforcements (bi-directional fabrics, mats and tissues hybrid), but keeping the processed common characteristics (weight, percentage of glass fibre) in the SMC(, common agents %, …..) in order to carry out a proper comparison between them in their final performance.

For its part, the chosen method of transformation has been the hot compression which allows a very large production rate because they are obtained low cycle times, with relatively low investment.

The preimpregnado manufactured presents conditions of processability, manipulabilidad and adequate reactivity (peak of exotermia curing and temperature) and the characterization of the manufactured part focuses on the final status of use to which it is intended and which has been defined by preceding paragraphs.

As most outstanding findings may point sheet designed in the project allow to compete with those commonly used in traditional sectors. So you can point of the sheet developed:

- The sheet base vinylester loaded with nanoparticles for coatings industry have adequate surface finish and abrasion resistance properties, however we do not provide input in the mechanical benefits expected, not exceeding the wool of rock or microspheres.

- These same sheet, filled with rock wool, to achieve a comparable nature epoxy mechanical performance, highlighted by their mechanical input matrix.

- The use of Rockwool with microspheres, provides an interesting combination with regard to the contribution of mechanical performance, but hinders the processing by the increase in viscosity.

- The nature vinylester-epoxy resins of generation, have mechanical properties appropriate for the replacement of the sheet of basis exclusively epoxy of difficult handling and conservation impact and bending.

- The sheet based on resin epoxy present limitation of its conservation, being reserved at - 20 ° C for the proper handling.

- A provision sandwich in compression of the developed prepreg, (bi-directional fabrics on the outer surface and the interior of short-fiber) allows you to define the optimal disposal to achieve the highest performance.

- The optimization of the percentages of the internal rusting and thermoplastic additive within the resínica paste is decisive to achieve maximum benefits.

Thermostable materials and especially structures sandwich type based on these materials have gained increasing importance in key areas such as the aeronautical and construction, replacing the metal materials mainly due to its good relations benefits/weight and the enormous resistance which involves the use of these materials.

The main reasons for the use of these sheet has been increased are among others its competitive cost, its good electrical insulation performance at high temperatures and high resistance to corrosive environments and abrasive media.

The following table shows the consumption in tons of sheet of major markets:

The technological innovation that brings this study is the application of the technique of compression for the manufacture of parts that currently had a high manual component and will require high times of cycle due to the applied techniques (autoclaves, manual moulding primarily).

So far in many areas of application of the composites is has predominated above all the security and the benefits/weight ratio, and the cost in the background. Today, and because of increasing competition, cost has progressively been gaining importance and hence, the thought of more competitive processes. The main objective is therefore increasing productivity and thus reduce the cost of labour without ignore the required mechanical performance.

There are other areas of application for this type of material, usually related to high mechanical performance:

- Wind sector. Currently used sheet of nature epoxy in the blades of the windmills, due to the high mechanical benefits that must submit these pieces.

- Sector constantly. There are many applications in this sector that use this type of material: keels, helmets for protection, etc.

- Footwear sector. The leading edge of the safety shoes must overcome high requirements on properties of impact so it is necessary the use of sheet of nature vinylester-polyester or epoxy.

- Transport sector. In structural applications they are using sheet type epoxy, while those intended for coatings are used in type polyester and phenolic depending on the required behaviour to fire requirements.

- Abrasives sector. The abrasive discs used usually sheet nature phenolic storage with abrasion-resistant loads such as carbide silicon, etc.

Experimental development

- Definition of specifications for part of the sheet manufactured and processed parts.

- Research and development of materials suitable for the manufacture of sheet actionable compression hot.

- Development of formulations and manufacturing of sheet at laboratory scale.

- Characterization of the sheet.

- Transformation of the sheet developed into the mould at laboratory scale.

- Characterization of processed parts.

Technical means

The main materials used are summarized in the following:

(a) resinous systems of different nature.

- Polyester resin

- Set resin vinylester and thermoplastic additive based on polyester, with a capacity of mature with magnesium oxide. The optimum benefits of such a system is defined by an adequate percentage of resin-additive incorporated and rusting internal parties.

- Latest generation vinylester resins with high-performance impact. Resins vinylester-Epoxy (1 and 2).

- Common epoxy.

(b) stiffener loads

- Silica gel.

- Microspheres.

- Rock wool.

- Fiber glass powder.

- Nanoparticles.

(c) specific additives for manufacture

- Maduradores agents suitable for resinous systems: magnesium oxide to mature base polyester formulations - vinylester, and high-performance vinilésteres.

- Liquid internal rusting, 1810-HT.

- Moisturizing agent.

- Agents catalysts and polymerization accelerators. Catalysis systems vinylester, polyester and are carried out through the joint application of heat and catalysts type peroxides systems epoxy through heat and the combination of the curing agent with amínicos catalysts

(d) reinforcement of glass of various erent and nature

- Bi-directional fiberglass fabrics of weight 800 g/m2 and 25 to 35 mm short fiber, for sheet with high mechanical performance.

Experimental method

This technician designates compound, commonly calls SMC (Sheet Moulding Compound).

The manufacture realises in the machine of manufacture of preimpregnados of SMC. The machine consists of two cubetas of dosage of the resinous systems (as it observes in the following diagram). The fine layer of resin, aditivada as it suit, dosifica and deposits on a film protective of PA, Polietileno, etc., one in the upper face and another in the inferior. These layers of resin soak the fabric or the fibre cut and go through a back stage of compactación in rollers of compactación.

The peculiarity of this product is the function played by one of the components: the agent of maduration. This espesante, being the most usual the oxide or hydroxide of magnesium, possesses the property to do change the viscosidad of the pasta of impregnación in the first moments of the process. The viscosidad of the pasta, the sufficiently flowed to achieve a good impregnación, increases until a value of several cientos of thousands of Poises. The product presents no sticky, for which the manipulation is simple.

The moldeo of compounds type SMC realises by compressesion between the mould and contramolde in hot.

Formulations and results

Then changed the nature of the resins using always the reinforcing agent selected as optimum. Finally, discusses the provision of the different layers of the SMC (alternating layers of tissue with short fibres).

Thus the processed formulations for a SMC of 2,000 g/m2 grammage and made up of a reinforcement combined bi-directional fabric of 800 g/m2 and 110 g/m2 from robing short fiber have the following composition:

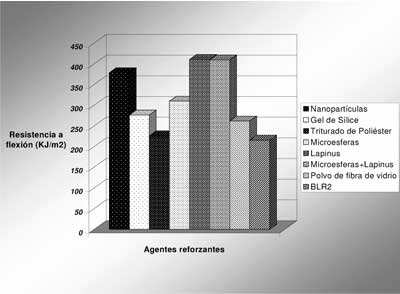

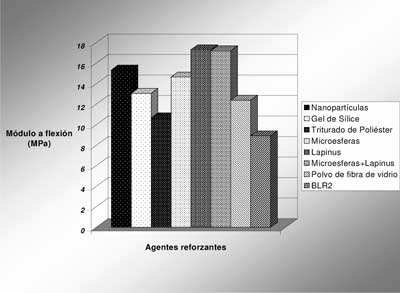

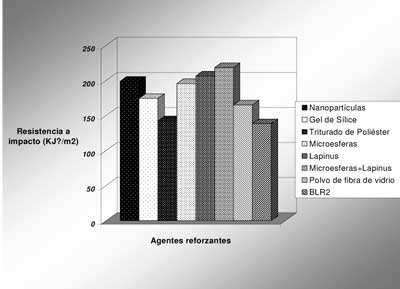

The stiffener agents used have been gel microspheres, lapinus, silica, powder of fiberglass, nanoparticles and microspheres with lapinus.

The results of the mechanical characterization after the compression hot 150 ° - 160 ° C in 180 s. cycles and a provision sandwich (woven into the view faces and mat inside) 2 SMC layers used for the filling of the mold you can see in the following graphs (Charpy impact test and essay of) (inflection):

Then formulations were conducted to analyse the influence of the additive anticontracción in the performance of the prepreg.

To this end, developed formulations was amended in the relationship resin vinylester thermoplastic additive anticontracción studying the following proportions: 70/30, 80/20 and 90/10 and 100/0.