LN Moldes participa en el proyecto europeo Hipermoulding

Cuenta con recursos suficientes para participar en esta iniciativa que tiene como objetivo principal optimizar el posicionamiento de los canales de refrigeración cerca de la superficie para obtener un mejor y más eficiente intercambio térmico en los moldes de inyección. El proyecto Hipermoulding es un programa de investigación colectiva donde los ejecutantes de la I+D promueven actividades de investigación tecnológica y científica por indicación de las asociaciones industriales y sus miembros asociados. Estos proyectos de I+D están patrocinados por la Unión Europea para ayudar a las empresas a mejorar su competitividad

“La industria quiere acortar los plazos de entrega, pero es complicado. Se requiere una gran conexión con el cliente y los fabricantes de moldes y piezas y equipar a las empresas con tecnología más puntera, automatizando procesos y sistemas que nos permitan ganar tiempos en todos los recursos de la producción”, comenta Leonel Costa, presidente de Ln Moldes. “Las piezas deben realizarse en dimensiones adecuadas y trabajar con las tolerancias correctas. En lo relativo a las máquinas, es importante que se rentabilicen más, para aprovechar el máximo rendimiento de la máquina con menos tiempo”. En cuanto a innovación la compañía intenta encontrar nuevas soluciones, innovar y rentabilizar en los procesos. “A corto plazo, queremos implementar una solución que pueda optimizar dotaciones, fabricación de molde, de piezas inyectadas y control de todo el proceso de producción”.

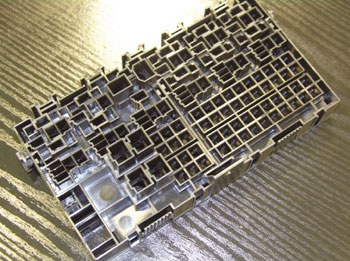

Son especialistas en moldes técnicos. “Son complejos –continúa el presidente– porque trabajamos con piezas que tienen que montarse con postizos y con tolerancias muy apretadas. Producimos una pieza de inyección de dos centésimas de tolerancia en molde técnico”.

La compañía puede producir moldes de hasta tres toneladas y en Planimolde, otra empresa del grupo, hasta diez toneladas. “También tenemos productos más complejos como la bi-inyección y los moldes con insertos metálicos. Somos uno de los mayores productores de este tipo de molde en Portugal. Tenemos los equipos para hacer los moldes y las pruebas, mediante plato giratorio, para probar los moldes y desarrollar la producción”.

Una gran experiencia en el sector de moldes

Fruto de esa evolución de forma paralela a las necesidades del mercado, LN Moldes es hoy un grupo de cuatro empresas que ofrece al mercado proyectos completos. Tiene capacidad para inyectar plásticos y desarrollar productos en plantas totalmente especializadas para cada actividad. Esta diversificación le permite ofrecer soluciones integrales y ofrecer un mayor valor añadido a cada producto.

Comenzó fabricando piezas para la industria de moldes para después, a partir de 1986 fabricar moldes complejos. Hoy la empresa es un grupo constituido por cuatro empresas dedicadas a la fabricación de moldes, a la inyección de plásticos y a la ingeniería. Hace tres años invirtieron 2,3 millones de euros en la adquisición de la primera compañía moldista certificada de Portugal, con 27 años de experiencia en el mercado.

Actualmente, el 90 por ciento de la producción de moldes se destina al sector de la automoción. También esto ha cambiado, ya que durante diez años se mantuvo como uno de los mayores suministradores de moldes de 1 a 32 cavidades para el sector eléctrico estadounidense.

“En el 91 y a raíz de la Guerra del Golfo el sector sufrió una recesión, después se estabilizó y antes de 2000 nuestro principal mercado era Estados Unidos, a donde exportábamos el 75 por ciento de nuestros productos. Hoy es al contrario, después del 11 de septiembre exportamos el 75 por ciento a Europa y el 25 por ciento a Estados Unidos y otros”, comenta Leonel Costa, presidente de LN Moldes. “Hoy en día algunos constructores de automóviles están intentando conectar más con moldistas e inyectadores de plásticos para controlar más los costes y cerrar más el círculo. Nosotros tenemos dos soluciones para la industria del automóvil. Una es la pieza más técnica, otra es la pieza más grande. Proporcionamos todo el interior del coche: moldes e inyección de piezas, así como conjuntos ensamblados, que es nuestro objetivo. Pero también trabajamos en nichos de mercado de cosmética e industria farmacéutica y estamos intentando suministrar al sector de la medicina, un área en la que ya tenemos experiencia”.

Esta compañía produce también moldes de múltiples cavidades y con canal caliente, que garantizan la intermutabilidad entre todas las cavidades. También tienen la capacidad de ejecutar estudios reológicos de todo tipo de plásticos, lo cual constituye un apoyo en la validación del proyecto.

En la producción generalizan el uso del equipamiento con control numérico principalmente en las áreas de fresado de alta velocidad, electroerosión, rectificación plana y cilíndrica y la medición tridimensional.

La mayor parte de sus productos se diseñan teniendo como base el modelado de sólidos, utilizando como software Cimatron y Pro-E. También su tecnología les permite fabricar moldes de alta cadencia, un acabado de superficie de alta calidad y un desarrollo del concepto original de las piezas.

Equipos

Un aspecto importante es el control de calidad. La conformidad geométrica está garantizada a través del uso de una vasta gama de equipamiento de control dimensional de donde destaca la máquina de medición 3D CNC, el proyector de perfil y el microscopio optométrico. Para la medición cuenta con dos laboratorios internos que hacen el control dimensional de los moldes y piezas inyectadas.

El área de erosión está equipada con máquinas CNC y cambio de electrodos por forma para garantizar un trabajo continuo sin intervención del operador. Todo el trabajo ejecutado es rigurosamente controlado, para garantizar la conformidad geométrica.

En cuanto al departamento de montaje, también cuenta con equipos humano y técnico cualificados que trabajan al detalle. Utilizan equipamiento de precisión en ambiente controlado técnicamente.

Para el sector de envase y embalaje puede hacer moldes de hasta 96 cavidades. Ofrecen altas prestaciones con ciclos cortos y espesores finos. Aseguran, además, la inexistencia de variación dimensional y peso entre cavidades.

Inyección de plástico como complemento