EcoAlf: complementos 100% reciclados

7 de enero de 2010

Desde finales de 2007 Fun&Basics está llevando a cabo su primer proyecto de compromiso con el medio ambiente, y ha desarrollado EcoAlf, un tejido exclusivo 100% reciclado y 100% reciclable con un aspecto, calidad, flexibilidad y resistencia iguales a los tejidos técnicos de alta calidad. Tras varios meses de investigación e involucrando a cinco fábricas diferentes, Fun&Basics, creó un tejido con soporte, obtenido a partir del reciclado de botellas de plásticos PET.

Conseguido el tejido, el reto de Fun&Basics pasa a una segunda fase, donde la creatividad y el compromiso medio ambiental se alían para que el equipo de diseño pueda dar un paso adelante y desarrollar los primeros productos Fun&Basics 100% reciclables.

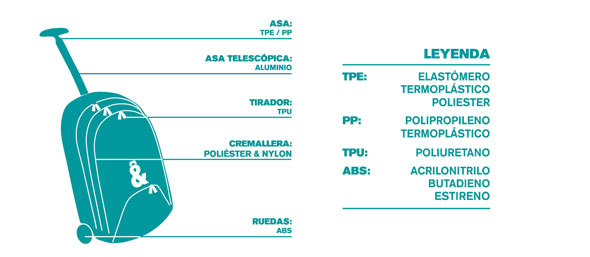

Fun&Basics se ha involucrado al máximo en su compromiso de I+D+i con este proyecto, y ha querido dar a los nuevos modelos –mochilas, bandoleras, zapatillas– un valor añadido, por lo que todos sus componentes han sido cuidadosamente seleccionados para que pudieran ser reciclables, libres de PVC, y así conseguir una colección 100% reciclable, con un tejido 100% reciclado.

Características técnicas de EcoAlf

EcoAlf es un tejido diseñado y desarrollado por Fun&Basics, que cuenta con aspecto, calidad, resistencia y flexibilidad iguales a los tejidos no reciclados más técnicos y de alta calidad. Se trata de una marca registrada por Fun&Basics para un tejido desarrollado a partir del reciclado de botellas de plástico PET y soporte ecológico TPE (poliéster elastómero termoplástico no tóxico), lo que le convierten en un tejido 100% reciclado y 100% reciclable. La compañía se propuso desde un primer momento, conseguir un tejido ecológico para poder fabricar sus productos, sin renunciar a la calidad y el diseño de sus demás colecciones.

La invención de EcoAlf es el resultado de la unión de un tejido con urdimbre y trama especiales y exclusivas, formado por dos hilos de poliéster 100% reciclado a partir de botellas de plástico PET, y soporte TPE libre de PVC, unido al tejido gracias a un adhesivo ecológico. Esta combinación convierte el tejido en 100% reciclado y reciclable. Pero además, EcoAlf presenta características únicas que la equiparan a las de materiales no reciclados y hasta ahora no obtenidas en un tejido reciclado: alta flexibilidad –que permite su fácil manipulación para conseguir diseños más elaborados–; no deformable; alta resistencia a la tensión, al desgaste y a las temperaturas extremas; impermeable; suave al tacto; ligero (un peso por metro cuadrado de 135 gramos); libre de PVC; un tejido no tóxico que puede utilizarse libremente en cualquier aplicación que entre en contacto con la piel humana.

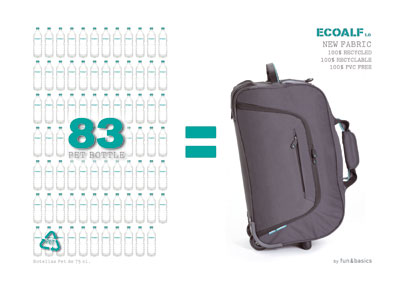

La aportación de Fun&Basics al cuidado del medio ambiente con este nuevo tejido EcoAlf tiene su traducción en números, es decir, se recicla por cada metro de tejido, con un ancho útil de 147 centímetros, un total de 70 botellas de plástico PET de 75 centilitros, contribuyendo a reducir la utilización de recursos nuevos, y alargando la vida útil de los ya existentes.

Proceso de producción

EcoAlf ha sido desarrollado en exclusiva por Fun&Basics, a través de una joint-venture con una empresa textil de Taiwán poseedora de la primera categoría textil ‘Green Mark’ otorgada en el país. Fun&Basics ha desarrollado su tejido ecológico EcoAlf involucrando a cinco fábricas diferentes que trabajan en exclusiva con la compañía para este proyecto. El proceso se lleva a cabo siguiendo las siguientes fases:

1. Centro de recogida: En esta fase todas las botellas pasan por el proceso de limpieza, clasificación y compresión. El centro es un gran almacén de plásticos, donde hay botellas de todo tipo y colores, pasando cada una de ellas por una gran máquina para su separación y clasificación. Seguidamente se les somete a un proceso de eliminación de residuos que no son plástico PET. A continuación se lleva a cabo el proceso de compresión, formando cubos perfectos de botellas aplastadas que se transportan a la siguiente fase.

2. Triturado: Las botellas en esta fábrica pasan por una máquina trituradora, que las convierte en escamas de plástico duro, que son almacenadas en un gran contenedor. Este contenedor lava los trozos de plástico a altas temperaturas, para conseguir la eliminación total de impurezas, restos de etiquetas, etc., para finalmente pasar por un proceso de secado y empaquetado. Los chips de plástico están preparados para convertirse en fibra textil.

3. Fibra textil/hilado: En una nueva fábrica, las escamas, a través de un proceso de fundición y cristalización, se convierten en fibra.

4. Confección del tejido: Las fibras de hilo, tras un tratamiento de peinado e hilado, se convierten en enormes ovillos de hilo (urdimbre), preparados para ser tejidos. En esta fase se define el grosor, trama, acabado, y resto de características técnicas del tejido necesarias para cubrir los requisitos del uso que se vaya a dar al mismo. Es en este momento donde se empieza a eloborar EcoAlf con las características técnicas exigidas por Fun&Basics. Todo este proceso está mecanizado y se realiza de telares mecánicos. El tejido una vez terminado, es sometido a un proceso final de control de calidad que se realiza de modo manual, revisando cada milímetro de tejido para eliminar cualquier imperfección.

5. Teñido: El tejido llega a este proceso en rollos de aproximadamente 1.000 metros. El tintado se realiza en una fábrica que podría describirse como una enorme lavandería, donde para conseguir un teñido uniforme es necesario introducir en los tambores la cantidad exacta de 5.000 metros. A continuación se realiza el secado y planchado del tejido a través de unas enormes máquinas de más de 20 metros de altura. Las pruebas de color se llevan a cabo en una especie de laboratorio, donde los colores se mezclan hasta llegar al deseado. En esta fábrica todo el agua que se utiliza se recicla y acumula en pozos donde se purifica para volver a ser reutilizada en el proceso. El tejido, con las peculiaridades exigidas por Fun&Basics, en cuanto a aspecto, trama, grosor y color, se empaqueta y plastifica en rollos de 1.000 metros, para su transporte a la última fábrica y proceso.

6. Soporte: La empresa encargada de esta última y definitiva fase, es una pequeña empresa dedicada a la producción de plásticos para soporte de tejidos que sustituyan al PVC, y que ofrezcan la misma resistencia y elasticidad sin dañar el medio ambiente. En esta empresa se ha desarrollado el soporte para el tejido EcoAlf, a partir del plástico TPE, un elastómero altamente resistente y que a diferencia del PVC es fácilmente reciclable y no contamina al ser incinerado. Este soporte aplicado al tejido reciclado lo convierte en un tejido altamente resistente, impermeable y flexible pero no deformable. El proceso de colocación del soporte se realiza a través de una gran máquina, donde el tejido se dispone totalmente tensado para que no quede las más mínima marca y el soporte se distribuya de manera uniforme. El soporte se une al tejido, gracias a un pegamento biodegradable que se extiende uniformemente por toda la superficie, en un proceso lento pero constante. Finalmente el tejido junto al pegamento pasa por unos rodillos a muy baja temperatura, donde el tejido se enfría y el soporte se endurece para dar el acabado final.

Los productos Fun&Basics con tejido EcoAlf

Fun&Basics se ha involucrado al máximo en su compromiso medio ambiental con este proyecto, y ha querido dar a sus nuevos modelos un valor añadido, por lo que todos sus componentes han sido cuidadosamente seleccionados para que pudieran ser reciclados, y así han conseguido piezas 100% reciclables.

Estos primeros modelos –trolley cabina, saco de viaje, neceser, mochila, bandolera y zapatillas– están fabricados con materiales 100% reciclables, libres de PVC, y con tejido EcoAlf.

Lo que pretende Fun&Basics

Para Fun&Basics un producto tiene que tener detrás una filosofía, un cocepto, y con esta idea la empresa ha creado un estilo actual, innovador y práctico presente en todas sus líneas de producto.

Con estas premisas, Fun&Basics que se ha mostrado siempre sensible a los cambios del mercado, las nuevas tendencias e inquietudes de la sociedad, se encuentra en un momento de fortalecimiento de la marca en tres pilares: compra funcional e inteligente, innovación, y nuevas tendencias de compra ecológica.

Para ello la empresa se ha marcado como objetivo desarrollar soluciones creativas a los desafíos actuales, buscando la forma que diseño, calidad y respeto hacia las personas y el entorno estén unidos y sean accesibles, sin perder una esencia dinámica, divertida, práctica y moderna, sin caer en la excentricidad y la pretensión.

La empresa pretende llegar a ser líder internacional en el diseño, fabricación, comercialización de bolsos, artículos de viaje, complementos y accesorios para personas que deseen llevar un estilo de vida sostenible, sin renunciar a la diversión, la moda y la funcionalidad.