Polímeros con nanotubos

6 de julio de 2009

El Instituto Químico de Sarriá (IQS) dispone desde 1994 del Laboratorio de Ciencia de los materiales, en donde el doctor Carles Colominas trabaja con nanocomposites, sintetiza capas por medio de la deposición química de vapor y la técnica Sol-Gel, vía húmeda, para obtener materiales ultra duros, con durezas de 10 a 40 veces superiores a las del acero. El centro más veterano en nanomateriales es AIN (Asociación de la Industria Navarra) en Cordovila. Añadamos el Instituto de Ciencia y Tecnología de Polímeros (CSIC), de Madrid, Aimplas (Instituto de tecnología de Polímeros), en Paterna (Valencia), y para terminar, citemos a Nanospain (www.nanospain.org). Cuenta con 275 grupos de investigación y 1.200 investigadores.

Pero a nivel industrial y comercial, ¿dónde encontramos una empresa que haga negocio con la nanotecnología? Hay alguna excepción que confirma la regla. Pere Castell, de Nanozar, afirma que la industria ve la nanotecnología como un mercado con alto riesgo, no asumible por ella, y que España sufre una falta de personal técnico altamente cualificado. Las propiedades ‘milagrosas’ de los nanomateriales son una realidad, pero convertirlas en un éxito industrial es más difícil todavía. El avance será continuo, pero lento.

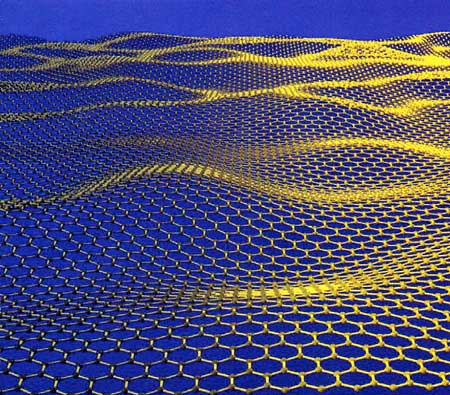

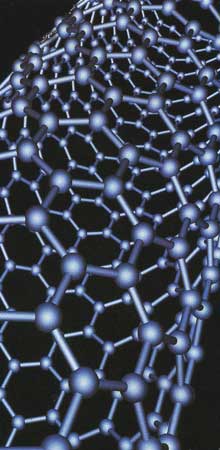

Hay muchas clases de nanomaterial, por ejemplo, las nanoarcillas (un tema fácil para refuerzo de polímeros) y los nanotubos de carbono, de una o muchas capas. Estos últimos son muy difíciles de manipular. Son redes exagonales de carbono trivalente curvadas y cerradas, que presentan una longitud de varias micras. Sus diámetros oscilan entre 1 y 20 nanómetros. Fueron descubiertos por S. Iijima, en Japón en 1991. Hay dos tipos: de pared simple, o monocapa, y de pared múltiple, hasta 100 capas.

Para comprender el problema, basta citar al NIMS (Nacional Institute for Materials Science), de Tsukuba, Japón. Los equipos de investigación de que disponen no los puede costear ninguna empresa, ni las de nivel internacional. Sólo el Estado: microscopia de alto voltaje y sincrotrón de electrones, entre otros.

La escala nano

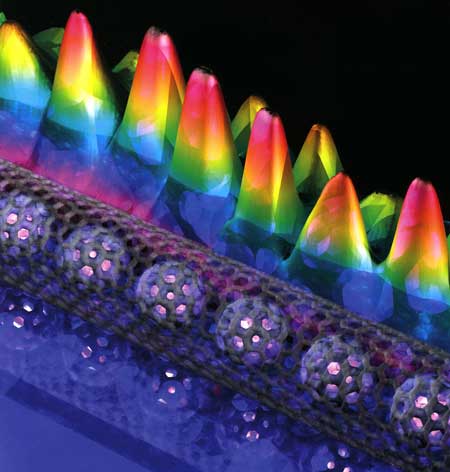

Los químicos, a través de estrategias de abajo arriba, han sintetizado materiales moleculares que presentan propiedades físicas de extraordinario interés. La nanoquímica constituye una herramienta de valor incalculable para la elaboración incluso de máquinas moleculares artificiales. Así opina Tomás Torres Cebada, desde su cátedra química de la UAM. El químico podrá ofrecer a los ingenieros electrónicos sistemas auto ensamblados, como ladrillos a escala molecular para la construcción de emisores-receptores electrónicos y electro-ópticos, de tamaño muy inferior al de los actuales en uso.

La nanoquímica manipula materiales a escala del nanómetro, entre 1-100 nm. Supone un impacto de varias órdenes de magnitud sobre la tecnología submicrométrica, que es la base de la electrónica actual. Su interés es obvio. Supone construir, a partir de piezas de materia como son los átomos y las moléculas, entidades supramoleculares en la escala nanométrica con propiedades específicas. Intenta manipular estructuras a escala molecular y dotarlas de nuevas propiedades, que no se encuentran en los materiales convencionales.

Los materiales moleculares se sintetizan aisladamente y se organizan en algún tipo de fase condensada, capaz de presentar propiedades físicas no convencionales. Las propiedades de los materiales nanoestructurados dependen de los efectos de tamaño, de los cambios de dimensionalidad del sistema. Los materiales nanocristalinos están formados por bloques habitualmente cristalinos, y existe una marcada diferencia con los vidrios y geles, que son microestructuralmente homogéneos.

La mejor energía para hacer trabajar a una máquina o interruptor molecular son los fotones y electrones. Una frase muy repetida, la que pronunció Richard Feynman el 29 de diciembre de 1959: There’s plenty of room in the bottom.

La fuerza o dureza del material cristalino, según el Efecto Hall-Petch, depende del tamaño del grano. A cualquier presión, a medida que el tamaño del grano decrece, el metal se endurece. El módulo de Young caracteriza el comportamiento del material elástico, según la dirección en que se aplica una fuerza, y para valores de tensión dentro del rango de reversibilidad completa de deformaciones. El valor del Módulo de Young se define mediante el coeficiente de la tensión aplicada al material y la deformación causada. Cuanto menor es el grano, mayor es el Módulo de Young, mayor es la fuerza que hay que aplicar, para que el metal entre en la zona de plasticidad.

Con el módulo de cizalladura ocurre lo mismo: cuanto menor es el grano, mayor es la fuerza que hay que hacer para lograr una deformación dada.

El efecto Hall-Petch vale para granos de un diámetro mayor de 12 nm. Para granos menores la dureza disminuye. Hay dislocaciones dentro de un grano, que se propagan a los granos cercanos, y debilitan al metal. A menor tamaño, más difícil es la propagación de la dislocación y la aparición de la plasticidad metálica. Pero los resultados prácticos no son alentadores, no confirman la teoría. La termodinámica sugiere que las nanoestructuras sintetizadas probablemente nunca conseguirán la uniformidad y perfección de los circuitos electrónicos logrados con cristales de silicio, obtenidos con la litografía convencional. La simple reducción de tamaño, por sí mismo, no puede aportar el esperado aumento de características.

Los nanotubos del Centro Nacional de Microelectrónica (CNM)

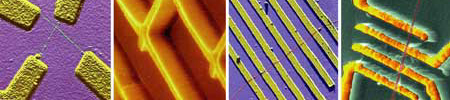

En el CNM trabaja el doctor británico Adrián Bachtold, quien ha hecho unas declaraciones que intentaremos resumir aquí. Intenta esclarecer las propiedades cuánticas de los NTC y su comportamiento en aplicaciones. El centro cuenta con la mayor sala limpia de España y con profesionales de amplia experiencia internacional. Están interesados por las propiedades mecánicas y eléctricas de los NTC. Por ejemplo: cómo circula un electrón a través del NTC, cual es su vibración, o ver, si hay fenómenos cuánticos y de qué tipo.

Tras haber fabricado el primer circuito lógico a partir de nanotubos, parece que se ha avanzado poco. Hace más de dos décadas que se habla de la posibilidad de sustituir el silicio por NTC, para mejorar sus prestaciones. Hasta que apareció nuestro trabajo en Science, en 2001, no pudo probarse, que se podía construir un circuito lógico con unas pocas moléculas. Eso no significaba que en poco tiempo aparecerían ordenadores basados en NTC. Hoy día conseguir NTC es algo sencillo y barato, pero su manipulación sigue siendo muy compleja. Por otra parte los NTC pueden comportarse como metales, semiconductores o superconductores. Recordemos aquí que el diamante, carbono puro es aislante.

No disponemos de técnicas para manipular los NTC con eficiencia. Además, se disponen de forma aleatoria sobre una superficie, lo que obliga a localizarlos, y no es nada sencillo. El NTC debe estar en una posición precisa sobre el sustrato (polímero), al que reforzará.

Los NTC pueden ser una buena opción para reemplazar al silicio. Las propiedades del NTC son claramente superiores a las de éste. Por ejemplo, fenómenos como la conductividad o la transductancia. Todo ello es importante, para que los circuitos funcionen a mayor velocidad, y por tanto, disponer de mejores transistores. Hay que dominar la ordenación de los átomos de carbono, que es lo que define, si va a ser superconductor o no.

Los NTC definen una estructura rígida, robusta y con una masa muy ligera, pero sabemos muy poco de otra propiedad mecánica: la vibración. Su comprensión abriría la puerta a muchas aplicaciones, desde optimizar el uso de energía en telefonía móvil, a la identificación de fuerzas débiles (sensores muy sensibles), o detectar la masa de un único átomo. También se espera mucho de la computación cuántica.

Antes que esto, lo que realmente importa es la ciencia básica, que se esconde detrás de los NTC. Por ejemplo, ver hasta qué punto los NTC se comportan según los principios de la mecánica cuántica. También interesa su comportamiento en función de la temperatura, o la fluctuación de los átomos a ese nivel.

La realidad es que todavía no comprendemos bien qué ocurre en la escala de lo nano. Hasta aquí el doctor Adrián Bachtold, del CNM. Si no se puede medir en la nanoescala, tampoco se puede avanzar en la nanociencia.

Es decepcionante, después de tanta investigación en ingeniería molecular, de nanosistemas, la falta de éxitos en la explotación tecnológica y comercial. La manipulación de estructuras moleculares es un tema muy difícil. Y no vale recordar que hemos modificado las estructuras de los polímeros, que hoy día encontramos por todas partes. Se trata de moléculas que podemos considerar grandes.

Producción de NTC

El método más conocido para la producción de NTC consiste en la sublimación del carbono en atmósfera inerte. También la descarga mediante arco eléctrico. Consiste en generación de plasma a través de una corriente entre dos electrodos de carbón, a una distancia de 1 milímetro y en atmósfera inerte. Los electrodos alcanzan los 3.500 °C. El alineamiento, rendimiento y calidad de los NTC dependen de las condiciones del arco y la estabilidad del plasma. Otros métodos son la ablación láser y la descomposición catalítica de hidrocarburos.

La quiralidad es una propiedad con la que hay que contar en los NTC. Un objeto quiral carece de ejes de rotación. Las moléculas quirales tienen la propiedad de desviar (rotar) el plano de luz polarizada, que las atraviesa. El plano se desvía cierto ángulo. Si la luz rota hacia la derecha, esa molécula es dextrógena, swi es a la izquierda, es levógira.

En los NTC la quiralidad equivale a la dirección en que se enrolla una hoja de grafito de un átomo de espesor para formar el nanotubo. De la hoja de grafito surge la cinta, que enrollada forma el NTC. Es fácil imaginar que la cinta se puede cortar a partir de la lámina formando diferentes ángulos, desde 0 hasta 90º. La quiralidad y, por tanto, las propiedades del NTC, dependen del ángulo de corte. No es posible lograr NTC de la misma quiralidad, porque unos NTC son metálicos (conductores) y otros semiconductores. Todos los tubos están formados ensamblando exágonos, pero la quiralidad varía. Es una mezcla.

El problema subsiste, igual en los tubos monocapa, que en los multicapa. Separar los NTC por quiralidad no es posible, porque, debido a las fuerzas atractivas Van der Waals, los NTC tienden a autoensamblarse, a formar fibras o madejas.

La noticia, de enero pasado, procede de Duke University. Jie Liu y Patricia Crawford afirman que han conseguido hacer crecer NTC exclusivamente de tipo semiconductor. Su mérito es haber logrado una combinación exacta de dos alcoholes con argón e hidrógeno, con cobre como catalizador. Habrá que confirmar su método.

Hay NTC de quiralidad cero: el nanotubo visto lateralmente muestra hileras de exágonos verticales, paralelas al eje del nanotubo. Los nanotubos con quiralidad poseen hileras de exágonos, que forman un ángulo con el eje del NTC. El entrecruzamiento de los NTC, al mezclarlos con termoplásticos o resinas, aumenta mucho la viscosidad.

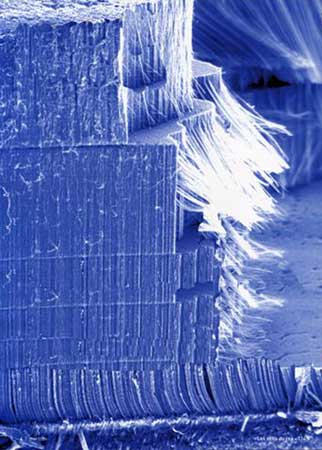

El método más práctico para seleccionar NTC es la deposición química de vapor que la realizan en el IQS, Barcelona. Se basa en la descomposición de hidrocarburos gaseosos (benceno o acetileno) llamados precursores, sobre un substrato grafito, cubierto por metales de transición (cobalto, hierro, níquel) que actúan de catalizador. Las temperaturas oscilan entre 700 y 1.500 °C. Los NTC de este método no son rectos, sino curvados, formando un conglomerado contaminado con catalizador. El diámetro de los NTC es bastante uniforme.

Cuando la pirólisis se lleva a cabo en presencia de compuestos organo-metálicos, se obtienen NTC alineados. El crecimiento de los NTC inicialmente es rápido, pero decrece mucho cuando el catalizador queda encapsulado en los NTC. La densidad es muy baja comparada con el grafito, lo cual es una gran ventaja para ciertas aplicaciones.

Las propiedades mecánicas teóricas de los NTC son fascinantes, pero en la práctica no se consiguen valores tan altos. Sus características dependen en buena parte de la elevada relación radio/longitud y de la relación superficie/volumen, lo cual a su vez supone un aumento drástico del área interfacial.

Además, son sumamente elásticos, o sea, candidatos ideales para refuerzo en polímeros, si comparamos con los reforzantes tradicionales. Por su capacidad para soportar altas deformaciones ofrecen una ventaja considerable sobre las fibras de carbono. Se presupone que se ha logrado una dispersión ideal en la matriz polimérica. Como los NTC presentan aglomerados, es un reto lograr una dispersión eficaz.

De hecho, la dispersión se logra a base de un mezclado, que actúa como una cizalla y que rompe los NTC. Si el mezclado es energético, disminuye la longitud de los NTC, lo cual no es grave. De hecho, la relación radio/longitud de los NTC sigue siendo alta, se reduce de 1.000 a 250.

Es el precio que hay que pagar para lograr una dispersión aceptable. Las propiedades finales del nanopolímero dependen del grado de dispersión y del alineamiento de los NTC. La orientación y el grado de alineamiento de los NTC se determinan con imágenes de TEM y por difracción de rayos X.

Los NTC aportan al polímero no sólo una gran mejora de las propiedades mecánicas, sino también eléctricas: conductividad, aumentada en 10 órdenes de magnitud, una ventaja sobre las cargas eléctricas conductoras.

El poliestireno, acrilonitrito-butadieno-estireno (ABS) y el polipropileno se utilizan para formar multicomponentes, donde la dispersión de los NTC se lleva a cabo usando un mezclador. La dispersión lograda se analiza mediante técnicas SEM y TEM.

La transferencia de carga de la matriz polimérica a los NTC está condicionada por la unión interfacial, por la estructura molecular del polímero y su capacidad de formar hélices ordenadas alrededor del nanotubo individual.

La distribución uniforme se consigue con una concentración de NTC baja, inferior al 1% en peso, al menos en el caso del PS y PMMA. Aumentar la concentración al 2,5 ó al 10% cambia las propiedades de carga, pero los inconvenientes superan a las ventajas.

Las matrices epoxi no se pueden reforzar con NTC, debido a las débiles uniones interfaciales entre ambas fases. Los enlaces químicos NTC-polímero dan lugar a una eficaz transferencia.

· Colominas, C. El laboratorio de los materiales del IQS apuesta por la investigación en nanotecnología de superficies. IQS 2004.

· Corrales, T. Aditivos basados en nanopartículas R. De Plásticos Modernos 2002.

· Dakajin, Olgica. Tiny tubes make the flow go. Lawrence Livermore National Laboratory. Febrero 2007.

· Edelstein, Daniel. Self-Assembly to make faster chips. IBM 2007.

· Igartúa, A. Comportamiento tribológico de los recubrimientos nanocristalinos de CrC-NiCr. Tekniker 2004.

· Montero, J. Una ventana al nanomundo. AIN, Cordovilla 2004.

· Perales Romero, E. Comportamiento colorimétrico de nanometales. Universidad de Alicante 2004.

· Poole, Ch. Introducción a la nanotecnologia. Reverté 2007.

· Rodríguez Muñoz, J.M. Zeolitas nanocristalinas. Universidad Rey Juan Carlos I 2006.

· Torres Cebada, T. Nanoquímica. Dpto. de Química Orgánica. UAM 2006.

· Veciana, J. Informe sobre nanomateriales moleculares. Instituto de Ciencias de los Materiales, Barcelona. NanoSpain 2007.