Entrevista a Gerardo Müller, director de ventas internacionales de Tebis

25 de mayo de 2011

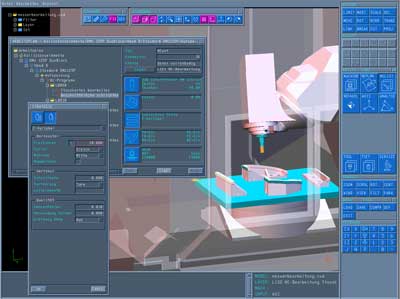

Con el objetivo de ofrecer una solución CAD/CAM con la que poder configurar los procesos de forma aún más productiva, 3.5 aporta técnicas CAD innovadoras y funciones automáticas adaptadas a la práctica que se podrán integrar sin problema en los procesos de construcción existentes. Tebis 3.5 está pensado para ayudar a reducir de forma drástica los costes por pieza. En Interempresas aprovechamos el viaje de Gerardo Müller a Barcelona para presentar este software ante sus clientes y amigos para que nos explicara con más detalle sus ventajas.

Para empezar, la versión 3.5 del software de Tebis, ¿qué mejoras aporta a una empresa del sector metalmecánico?

Lo más importante es que cada cliente hoy tiene su propio conocimiento. Los medios de producción se pueden comprar en todo el mundo, y el único capital de las empresas en sí es el conocimiento que tienen para utilizar estos medios de producción. Y este conocimiento depende mucho del personal. Muchas empresas tienen grandes problemas con la fluctuación de personal, despidos, gente joven no formada adecuadamente, jubilaciones... Y las empresas deben invertir capital en formar y mantener el conocimiento dentro de la empresa. Tebis permite recopilar y almacenar este conocimiento dentro del entorno del software. Un conocimiento costoso y valioso para la empresa que si se pierde o ciertos empleados no lo comparten, cuesta dinero a la empresa.

¿Se convierte en un valor de propiedad de la empresa?

Exactamente, y ahora por primera vez se puede proteger. Y esto es algo es muy importante porque todas la empresas quieren acceder a mercados más económicos, como China, pero sin hacer público su conocimiento. Esto es lo que permite Tebis: que nuestros clientes puedan fabricar en China pero manteniendo su conocimiento protegido bajo su responsabilidad. Es una situación única y no hay ningún otro software del mercado que lo permita.

¿Hasta qué punto está este tipo de software integrado en el sector del metal?

Todas las empresas de este sector tienen máquinas de control numérico, todas tienen acceso a la compra de herramientas de corte de alta tecnología, utilizan sistemas de software, sistemas CAM... pero todas utilizan un conocimiento individualizado. Es decir, el operario del software, el de la máquina, el que conoce las propiedades cortantes.. son personas singulares y no todas comparten esta información. Por un lado porque es difícil de documentar y por otro, porque existen rivalidades, no hay interés a la hora de compartir datos... Y en empresas de según qué tamaño, la gerencia tampoco no tiene noción de qué es lo que se puede guardar hoy en día en un sistema de fabricación. La gerencia conoce bien su sistema de contabilidad pero a menudo, vemos que la secretaria de gerencia utiliza un sistema Microsoft Office pero sin plantillas implementadas y escribir una carta es empezar con una hoja en blanco en vez de abrir una plantilla predefinida. Este concepto se puede ampliar al taller.

Están demasiado jerarquizadas; gerencia no sabe qué ocurre en el taller...

Sí, y al revés también. Muchas veces los usuarios tienen la idea de que hay mejoras que se pueden implementar, pero sea por la carga de trabajo o porque no existe una directiva por parte de gerencia para mejorar esta situación, no se produce el cambio ni fluye la información.

Y en Tebis, ¿qué retos tecnológicos encuentra a la hora de desarrollar este tipo de software?

Lo cierto es que no nos encontramos con muchos problemas. En Tebis hemos introducido un servicio de consultoría porque teníamos clientes que, por la propia carga de trabajo, no pueden dar el paso a hacer el caso ni tenían acceso a una autoridad externa de les hiciera una propuesta de mejora. Si bien es cierto que hoy en día existen muchas consultorías, éstas son empresas que no trabajan a nivel de taller. Por eso en Tebis creamos una empresa sólo dedicada a ello: Tebicon, Tebis Consulting.

Como director de ventas internacionales, ¿qué diferencias ve entre España y otros países de la UE en cuanto a la penetración de estos sistemas?

Sí, muchas diferencias. Como creadores de software tenemos ya una ventaja competitiva respecto a nuestra competencia, y es el servicio precisamente de consultoría individualizada. Y hasta el momento el acceso a este tipo de servicio lo estamos viendo en Alemania —nuestros principales clientes son alemanes— mientras que en otros países apenas se está generando. Hace dos años invertimos un importante capital en la compra de una base de clientes en España y pasamos de tener un representante a tener una delegación propia: Tebis Iberia, que ya está empezando a ofrecer servicios de consultoría, lo que permite mejorar el servicio al cliente y, por otro, abrir puertas a nuestro producto.

¿Y qué puede decirnos de su implantación en mercados como Latinoamérica?

Están incluso por delante. Por ejemplo en Brasil, un mercado que casi no ha tenido crisis y donde existe una importante inversión por parte de empresas europeas que implantan centros allí y que invierten en máquinas de producción en ese país, inversión que sólo se justifica si éstas trabajan efectivamente y planificando previamente un proceso de producción. Son máquinas costosas y la decisión para invertir se basa en varios factores y uno de ellos cuenta con la ayuda de Tebis para automatizarlas.

¿Cómo trabaja Tebis con las empresas?

Primeramente es necesario analizar la situación actual. Como segundo paso, se descubren oportunidades o errores dentro de la empresa, que representan un potencial de ahorro y en Tebis les mostramos cómo acceder a este potencial de ahorro por medio de una mejora que puede ser una implementación, una formación o una inversión en máquinas o software nuevo. Si el cliente estudia nuestra recomendación, nuestro análisis, entonces tiene una base para tomar una decisión y si decide tomarla, también le mostramos los pasos para lograr esta meta.

Normalmente todos los clientes están a ciegas, trabajan entre neblinas y no tienen un radar para tomar una decisión.

Utilizar un software como el 3.5 de Tebis permite optimizar y agilizar los procesos de producción, avanzándose a posibles problemas en su fase de diseño. ¿Se entienden así, como una inversión entre las empresas, o como un gasto?

No, son sobre todo las pequeñas empresas las que apuestan primero por estas oportunidades porque es el mismo dueño el que toma las decisiones. No hay diferencia entre las empresas por su tamaño.

Y en Alemania precisamente la mayoría de nuestros clientes son pequeños talleres y empresas de reducidas dimensiones.

En los Encuentros de Mecanizado, Alejandro Arjona, director general de la compañía, centró su ponencia en cómo optimizar procesos en los talleres de mecanizado. ¿Qué aporta Tebis en este campo, y qué mejoras el 3.5?

Hoy en día estos talleres quieren utilizar un software que les garantice que sus herramientas no sufran colisiones, algo importante porque una colisión es muy costoso para una empresa. La pieza puede salir dañada o la misma máquina y su reparación cuesta tiempo y dinero.

Evitar una colisión sólo se puede hacer si la herramienta física se está utilizando también en forma virtual dentro del software. Y todos nuestros clientes tienen una gran variedad de herramientas. Por motivos históricos han comprado a diferentes proveedores pero no están documentadas. Están en el taller y el capataz del almacén sabe dónde están, pero el mismo dueño de la empresa no tiene una visión clara de qué tipo de herramientas están a su disposición.

El primer paso entonces es montar una librería de herramientas. Eso es un esfuerzo enorme pero que trae consigo muchas ventajas, como evitar colisiones. Hay que tener en cuenta que un taller es un entorno vivo y las herramientas con el tiempo van cambiando. Hay que delegar y establecer quién es el responsable de comprar las herramientas o quién las debe catalogar. Y esas responsabilidades muchas veces no existen.

En este momento es cuando desde la consultoría de Tebis les podemos ayudar. A abrir los ojos y saber cómo organizar el taller.

Y habrá que ir introduciendo las nuevas herramientas a medida que se vayan adquiriendo, claro.

Sí, en la librería que se ha organizado. Además, estas herramientas tienen propiedades diferentes según qué materiales o máquinas que se vayan a utilizar. Ese es un conocimiento individual del cliente, no es de Tebis, y nosotros mostramos cómo puede añadir esta información dentro de la librería virtual y almacenarla allí.

Hoy en día encontramos muchas empresas que tienen una lista junto a cada máquina y cada operario sabe utilizar SU máquina.. pero es muy difícil cambiar un operario de máquina, porque esté enfermo o lo que sea.

Los programas que incluye Tebis en la versión 3.5 son individualizados a cada máquina, y eso es una gran ventaja. Permite intercambiar el personal sin perder tiempo, y también la formación del personal también es mucho más fácil. La formación especializada se ofrece a unas pocas personas autorizadas para determinadas tareas, como la compra de herramientas o autorizadas para establecer un nuevo proceso de mecanizado. Estas personas son pocas, pero los usuarios se pueden intercambiar.

¿Si los talleres compraran herramientas más estándares sería también más fácil el intercambio de información?

Claro. Además muchas veces no existen estándares documentados, y cada operario tiene su propio estándar y la misma variedad de estándar dificulta el funcionamiento en la empresa. Incluso muchos operarios tienen procesos de diferentes niveles y a veces prefieren un programa de un cierto programador, porque piensa que son más seguro, porque los conoce más, porque cree que tiene más experiencia… ¿Por qué no es posible establecer un estándar de programación o un estándar de herramientas que se van a utilizar en una empresa? Aquí es donde Tebis ayuda a abrir los ojos.

¿A qué sectores pertenecen principalmente sus clientes?

El 90% de nuestros clientes trabajan para el mundo del molde, troquel o diseño automotriz. Y el 10% trabajan para aplicaciones especiales, ya sean turbinas, energía, plantas nucleares, incluso algún cliente que trabaja en modelos de arquitectura, biomedicina —geometrías de reemplazo, prótesis— etc.

Para ejecuciones similares basta la misma programación

Tebis 3.5 permite además que, para ejecuciones similares se puede utilizar una misma biblioteca de programación. Algo único aunque no difícil. La palabra mágica detrás de esta tecnología es la automatización. Y ésta sólo es posible si tengo acceso a la información para tomar decisiones. En el momento en que puedo almacenar información dentro del software, puedo abrir la puerta a la automatización.