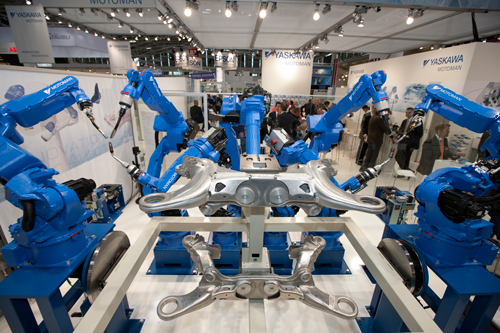

Automatica 2012 presenta soluciones para la industria del automóvil

16 de marzo de 2012

Una mirada a las calles o a las salas de exposición de los concesionarios lo demuestra: los fabricantes de automóviles ofrecen cada vez más variantes de los mismos modelos básicos. De esta manera se reduce el número de unidades de cada modelo. Esta tendencia exige soluciones de automatización más flexibles, un tema central para los fabricantes de robótica en Automatica. La clave se encuentra en el software: La programación de los robots y las líneas de robots se configura de manera cada vez más sencilla e intuitiva, de tal forma que es posible realizar con mayor facilidad y rapidez las adaptaciones.

La unificación y la integración de funciones prevén incrementar también la sencillez y la flexibilidad. Hasta ahora, por ejemplo en el pegado, se disponía de pistolas pegadoras, robots y técnicas de transporte que requerían controles individuales propios. En el futuro se prevé que los tres compartan un mismo control. De esta manera pueden evitarse las interfaces y la complejidad.

El pegado automatizado permite una construcción ligera refinada

En la fabricación de automóviles, el pegado automatizado es cada vez más importante para las empresas de automatización. Esta técnica de ensamblaje recibe un impulso adicional por la necesidad de ahorrar combustible y el mayor uso de vehículos eléctricos. En ambos casos, es imprescindible una construcción ligera refinada. Aquí se utilizan materiales imposibles de soldar como plásticos y materiales compuestos. También es interesante para las combinaciones de materiales que no pueden unirse a través de métodos “clásicos” de soldadura, como ocurre con el acero y el aluminio.

Un campo completamente nuevo para los oferentes de sistemas robóticos y para las empresas de técnicas de montaje y manipulación es la fabricación de baterías para los vehículos eléctricos. Porque hasta la fecha no se habían combinado celdas de iones de litio formando unidades tan grandes como ocurre en los motores eléctricos. Así se originan tensiones continuas entre 200 y 400 V que requieren nuevos mecanismos de seguridad también en la producción.

La fabricación de baterías, la electromovilidad en general y los diferentes temas de construcción ligera de la industria del automóvil son temas que tratarán los ponentes del Foro de Automatica, que tendrá lugar diariamente en el pabellón B1. El 23 de mayo será el día de la automoción, en el que el foro se dedicará durante toda la jornada a los retos de la industria de la automoción como un sector clave tradicional para la robótica y la automatización.

Entre los ponentes cabe citar a Arne Lakeit, director de Planificación de la Producción de Audi AG sobre el tema “A la vanguardia de la técnica: En los productos y en los procesos”, Daniel Schäfer, director de Diseño de Producción project i, BMW Group acerca de ‘BMW Megacity Vehicle: Comienzo de una nueva era con materiales compuestos de carbono’ o Benjamin Bickel, colaborador científico del Centro Tecnológico Bávaro de Técnica Motriz Eléctrica (E|Drive-Center) en la Cátedra de Automatización de la Fabricación y Sistemas de Producción sobre ‘Montaje de movilidad eléctrica en Alemania como sede de producción: Cómo afrontar los retos con planteamientos robóticos modernos’.

Un especialista de la construcción ligera, más exactamente en la fabricación de materiales compuestos de fibras de carbono, ha declarado Automatica 2012 como uno de sus principales temas. Bajo el título ‘Composite Production Automatizada (ACP)’ tendrá lugar una exposición especial y un área de innovación con la posibilidad de conversar con expertos. Entre las ofertas más destacadas al respecto en el salón cabe citar la ‘Automated Composite Production Innovation Area’, donde se mostrará en directo y en cooperación con institutos de investigación, soluciones automatizadas para la fabricación de materiales compuestos con fibras.

Solución completa para la integración óptima del proceso de soldadura

También en la construcción ligera, las técnicas de ensamblaje “calientes” como la soldadura siguen constituyendo uno de los retos centrales de la técnica de montaje y manipulación. Especialmente en la fabricación de portaejes, carrocerías con puertas y capós incluidos, parachoques y sistemas de escape, dominan tecnologías de soldadura muy diversas como la soldadura por puntos de resistencia o por arco voltaico. Junto a la necesidad de incrementar la rentabilidad y la calidad, la seguridad de los procesos de los sistemas automatizados y la documentación automática de los resultados desempeñan aquí un papel cada vez más importante.

Los sistemas informáticos industriales brindan soluciones integrales: desde la preparación racional asistida por ordenador de los procesos de trabajo, pasando por la automatización e interconexión de los sistemas individuales para formar unidades de fabricación, hasta la documentación automatizada de los procesos de trabajo y de cada producto soldado. En todos estos procesos, la sintonización y la interconexión con los componentes de hardware y software como robots, dispositivos de manipulación o sistemas informáticos son procesos muy exigentes. Por esta razón, los fabricantes de sistemas de soldadura desarrollan y optimizan constantemente los puntos de conexión correspondientes.

Optimización de la calidad en ‘tiempo real’ con la inspección en línea

Para satisfacer las exigencias de calidad cada vez mayores de la industria del automóvil, el procesamiento industrial de imágenes proporciona las tecnologías clave. La moderna técnica de medición en línea tridimensional, que destaca por su elevada exactitud, permite hoy realizar de forma rápida —y a medida de las necesidades de los procesos— las más diversas tareas de medición en la carrocería bruta, directamente durante el proceso. De esta manera, los datos de medición obtenidos pueden utilizarse directamente para optimizar la calidad en la producción.

En la industria del automóvil, la inspección de los cordones de soldadura suministrará cada vez más también los datos para una inspección manual completamente automatizada, lo que incrementará notablemente la eficacia. En lugar de decidir solamente si una pieza vale o no vale, el sistema de inspección de los cordones deberá diferenciar inequívocamente los fallos o comunicar la posición de los mismos. Desde el punto de vista funcional, la inspección de la superficie desempeña un papel cada vez más importante. Así, por ejemplo, fallos en la superficie de juntas de culatas pueden acarrear más tarde fallos de funcionamiento. El procesamiento de imágenes dispone para ello de complejos sistemas de inspección con software de verificación especial, dispositivos de exposición a la medida y cámaras de líneas.

El amplio abanico de las tecnologías relevantes para la industria del automóvil en Automatica convierte el salón en un foco de atracción para el sector. Dichael Zürn, Senior Manager Process Engineering, Daimler AG, subraya: “Automatica es una feria que reviste gran importancia para nosotros. Exhibe todas las tecnologías de automatización y el estado actual de los desarrollos. Para mí, Automatica es 'el' salón. En lo que respecta al contenido, aquí se representa un vasto abanico al que se suman algunos oferentes punteros con tecnología de montaje realmente innovadora”.