Antiguas normas UNE bajo la nueva filosofía GPS: normas EN ISO 286-1/2:2010

12 de abril de 2011

Durante el año 2010, se han publicado las nuevas normas UNE EN ISO 286-1 [3] y UNE EN ISO 286-2 [4], que recogen toda la información necesaria para el buen uso y aplicación de las calidades e intervalos de tolerancias dimensionales en las cotas de piezas. Si bien estas normas se basan en lo que se ha venido haciendo clásicamente en la industria, en este artículo presentaremos las modificaciones más relevantes y un formato nuevo en el que se recoge la información más importante y facilita enormemente el uso de las normas.

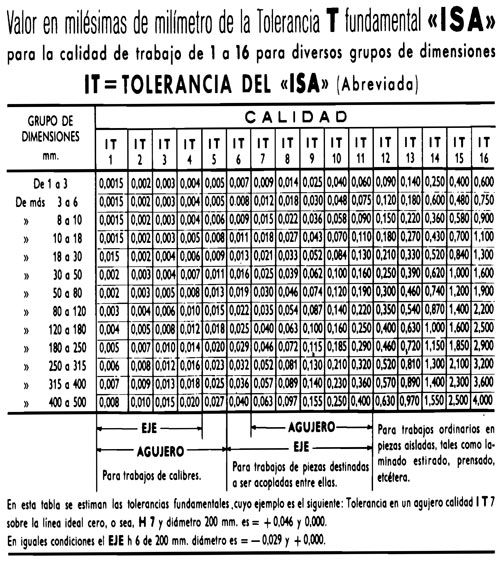

Un poco de historia. Tabla de tolera ISA

La ISA fue fundada en 1945 como ‘The Instrument Society of America’ (La Sociedad de Instrumentistas de América) y actualmente ISA es ‘The Instrumentation, Systems and Automation Society’ (La Sociedad para la Instrumentación Sistemas y Automatización); lo que le confiere un carácter global.

Desde el principio ha sido una sociedad creada para fomentar la aplicación de la Instrumentación, Sistemas Computacionales así como Sistemas de Medición y Control para procesos de Fabricación y Procesos Continuos. La sociedad es una organización educacional de carácter no lucrativo, que brinda beneficios a alrededor de 40,000 miembros en todo el mundo. Se reconoce a nivel mundial como la organización profesional líder de los especialistas de la Instrumentación. Está integrada por ingenieros, científicos, técnicos, educadores, proveedores, gerentes y estudiantes, quienes diseñan, utilizan o venden los sistemas de Instrumentación y Control.

La sociedad realiza una amplia gama de actividades, que ofrecen a sus miembros la oportunidad para la frecuente interacción con otros especialistas de la instrumentación en sus comunidades. Mediante la participación en las diferentes divisiones ISA, los miembros comparten ideas y experiencias con colegas alrededor del mundo. Estas divisiones se clasifican temáticamente en ciencias e industrias que representan a las distintas ramas de trabajo, dentro de la Tecnología de la instrumentación y el control industrial (ver Divisiones de ISA).

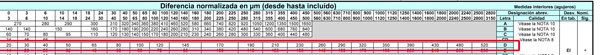

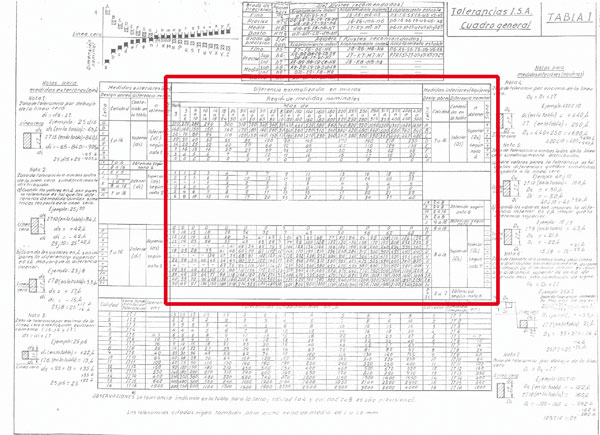

Recogiendo la experiencia de la industria, ISA publicó unas tablas que mostraban los intervalos de tolerancias más utilizados en la industria, tal y como se recoge en el ‘Manual que Máquinas. Cálculo de taller’ de A. L. Casillas [1], y que sirvió de referencia durante muchos años.

En dicho sistema, se contemplaban 16 intervalos de calidad para unas dimensiones nominales entre 1 y 500 milímetros, y con unos valores que se ajustaban a las posibilidades en la fabricación y control de aquel momento.

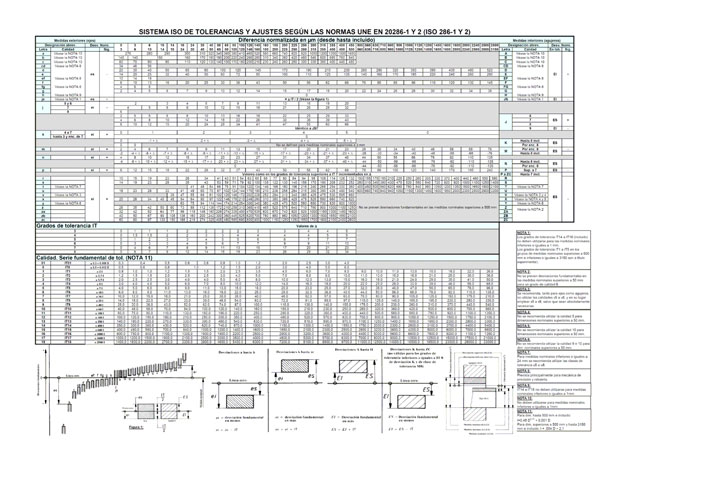

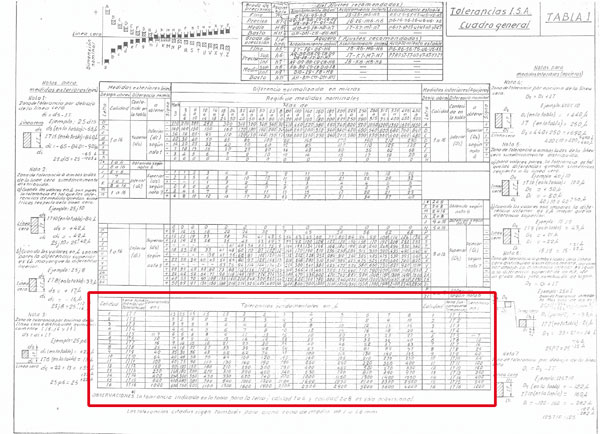

Aunando dicha información con la posición de cada intervalo de tolerancia, en la Universidad Pontificia de Comillas, se vino trabajando con un formato más práctico y que es el que se adjunta (figura 3).

Durante más de 10 años, esta tabla ha servido de material de estudio a los alumnos de Ingeniería Industrial, siendo un apoyo significativo y eficaz. De la experiencia acumulada por los profesores del área de Metrología Dimensional principalmente, se decidió actualizar la documentación a la nueva normativa ISO, pero manteniendo el formato anterior, que había demostrado sobradamente su validez pedagógica.

El relevo: ISO

La universidad, a través de los autores de este artículo, participa y representa a España en el Comité de Normalización ISO/TC 213 ‘Geometrical Product Specification and Verification’ donde se desarrolla la normalización relativa a las tolerancias dimensionales, geométricas y microgeométricas entre otras.

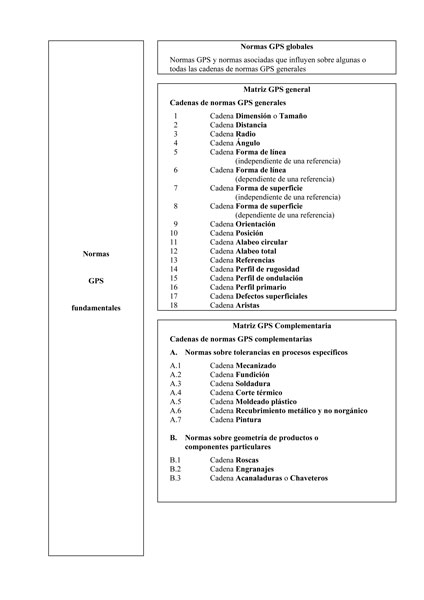

Todas ellas se basan en el concepto GPS, Geometrical Product Specification, cuya filosofía se fundamenta en los siguientes pilares, tal y como se recoge en [2]:

- Cubrir varios tipos de normas; algunas de ellas se ocupan de reglas básicas de las especificaciones (normas GPS fundamentales), otras de principios y definiciones globales (normas GPS globales), y otras se ocupan directamente de las características geométricas (normas GPS generales y complementarias) (véase figura4).

- Cubrir varios tipos de características geométricas, tales como dimensión o tamaño, distancia, ángulo, forma, situación, orientación, rugosidad, etc. (véanse las cadenas de normas GPS generales, numeradas del 1 al 17 en la figura 4).

- Estudiar las características de las piezas (sistemas de tolerancias) como resultado de diferentes procesos de fabricación, y de las características de productos (componentes) específicos (véanse las cadenas de normas GPS complementarias numeradas desde A1 a A7 y desde B1 a B3 en la figura 4).

- Intervenir en las diversas etapas de desarrollo de un producto: diseño, fabricación, metrología, aseguramiento de la calidad, etc.

- Los cuatro tipos diferentes de normas GPS forman lo que se denomina matriz GPS.

Esta matriz permite una clasificación rápida de la normativa y un acceso a la información muy interesante.

En esta línea, se han introducido conceptos nuevos como el de operador (distinto al de operario), operación, modelo de piel, etc., que si bien, muchos ya se venían manejando en la Industria, la normativa no se había hecho eco de estas tendencias hasta ahora, de ahí el interés de seguir muy de cerca esta nueva Normalización.

Las nuevas normas clasificadas y editadas bajo esta filosofía son documentos completos, autosuficientes y homogéneos, que aunque optimizables, constituyen una aproximación muy adecuada a una problemática que hasta el momento se había abordado muy tímidamente.

Las normas UNE EN ISO 286-1/2 ‘Especificación geométrica de productos (GPS) – Sistema ISO para las tolerancias dimensionales’ [3] y [4], publicadas durante el 2010, están desarrolladas bajo esta filosofía, además de incluir nuevos intervalos de tolerancia y contemplar dimensiones superiores a los 500 mm. En la matriz GPS de la figura 4, estas normas afectan al eslabón 1 de las cadenas de normas generales sobre dimensión o tamaño, distancia y radio.

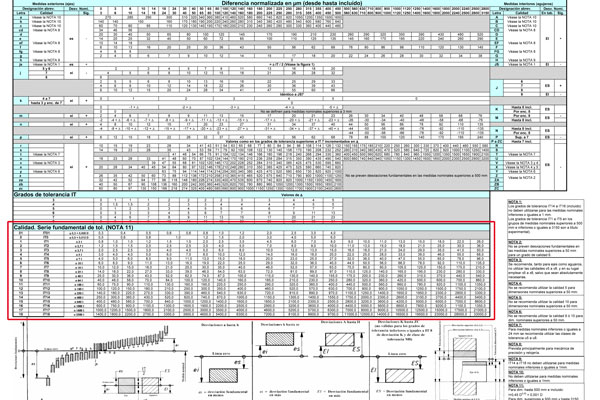

Al ampliarse el rango de dimensiones a las que aplicarlo se contemplan dimensiones desde 0 hasta 3.150 milímetros, y calidades desde 00 hasta 18. Con ello se da respuesta a nuevos métodos y un margen mucho más amplio de dimensiones.

También se han modificado los valores de los intervalos de tolerancia que anteriormente se venían utilizando, pues los métodos actuales son más precisos y versátiles.

Una nueva herramienta. Formato tabulado de la información ISO

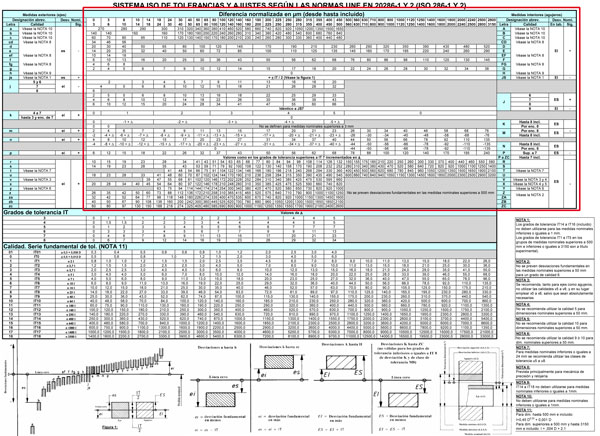

Después de años de experiencia, se ha concluido en el área de Metrología Dimensional de la Universidad, que el formato de la figura 3 resulta no sólo pedagógicamente muy útil, sino que ha demostrado ser parte del material de bolsillo de los ingenieros en su labor diaria. Por ello, se decidió adecuar la nueva información publicada en un formato similar. Evidentemente, esta nueva tabla no pretende sustituir a la normativa, sino que es una herramienta más que facilita el trabajo con las normas. No es lo mismo manejar dos normas que suman un total de 50 + 57 páginas, que una tabla resumen en formato A3. La tabla desarrollada es la que se muestra a continuación.

Si bien el manejo de la tabla resulta prácticamente inmediato para todos aquellos que están habituados al uso de las tolerancias dimensionales, se ha tomado la libertad de incluir un ejemplo que muestra cómo utilizar dicha tabla y se compara con el resultado obtenido si se siguiera con el sistema ISA.

Manual de uso de la tabla ISO

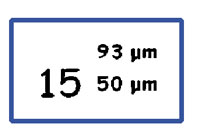

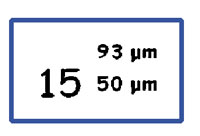

Se describe el modo de utilización mediante el cálculo de la tolerancia asociada a la cota 15 D9 de un agujero.

1. Tabla ISO. Cálculo de la tolerancia 15 D9

De aquí en adelante se utilizará una imagen reducida de la figura 6 para simplificar.

Pasos a realizar:

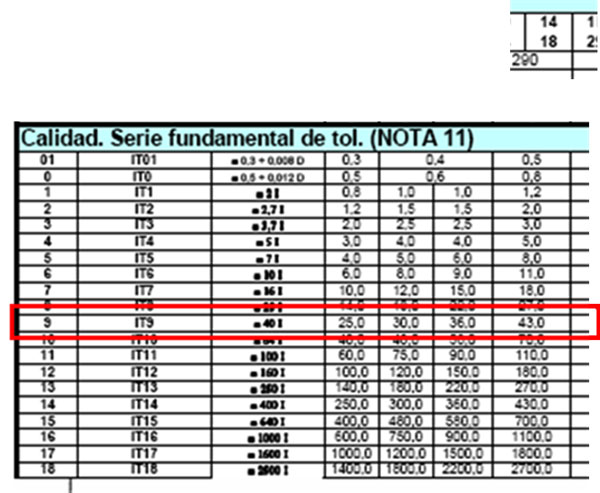

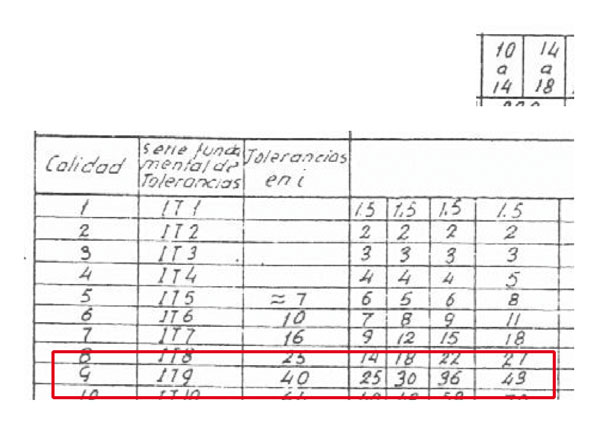

Búsqueda del intervalo de tolerancia asociado a la calidad 9 para una dimensión de 15 milímetros, en la zona de la tabla indicada en la figura 7.

Para un IT9 y una dimensión entre 14 y hasta incluido 18 milímetros, resulta un IT de 43 micrómetros.

2. Determinar la posición de la zona de tolerancia D

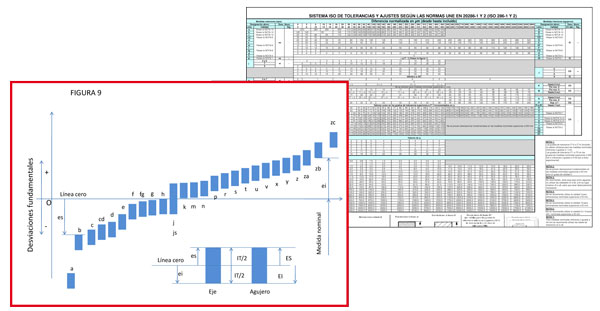

En la tabla se muestra sólo la gráfica para posiciones en ejes para simplificar, dado que es simétrico con respecto al eje horizontal. En la norma, evidentemente se recogen los dos casos, pero no hay que olvidar que este es un formato que busca la simplicidad y facilidad de manejo.

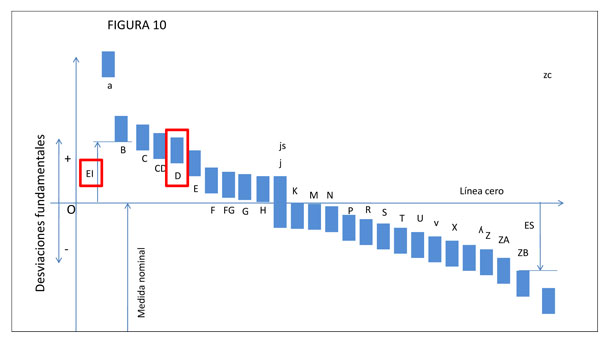

Con ello, se recurre a la gráfica de la tabla, figura 9 y usando dicha información o su simétrica (figura 10), se obtendría que la posición es la que se recuadra en la última figura.

De esta figura, se concluye que en la tabla superior se suministrará la Di ó Ei de la cota que interesa.

3. Buscar la Di en la parte superior de la tabla (véanse la figura 11 y 12).

Resultando Di = 50 μm.

4. Expresar el valor de la cota con su tolerancia.

Tabla ISA. Cálculo de la tolerancia 15 D9

De aquí en adelante se utilizará una imagen reducida de la figura 3 para simplificar.

Pasos a realizar:

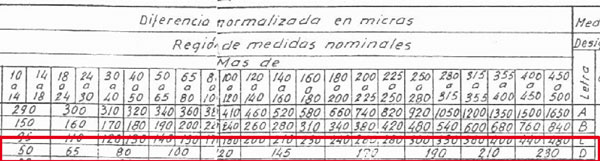

1. Búsqueda del intervalo de tolerancia asociado a la calidad 9 para una dimensión de 15 milímetros, en la zona de la tabla indicada en la figura 14.

Para un IT9 y una dimensión entre 14 y hasta incluido 18 milímetros, resulta un IT de 43 micrómetros.

2. Determinar la posición de la zona de tolerancia D.

Con ello, se recurre a la gráfica de la tabla, figura 16 y usando dicha información, se obtendría que la posición es la que se recuadra en la última figura.

De esta figura, se concluye que en la tabla se suministrará la Di ó Ei de la cota que interesa.

3. Buscar la Di en la parte superior de la tabla (véanse la figura 17 y 18).

4. Expresar el valor de la cota con su tolerancia.

Conclusiones

El uso del sistema ISA o ISO, es perfectamente válido siempre y cuando se especifique adecuadamente cuál es el utilizado, de manera que no dé lugar a confusión, y en algunos casos el resultado es el mismo tal y como demuestra el ejemplo anterior.

Se recomienda la utilización de intervalos de tolerancia normalizados pues, conducirá a:

- una reducción de costes, hasta ahora causados por la fabricación de piezas inadecuadas, consecuencia de una especificación incompleta;

- al equilibrio económico óptimo entre la especificación, fabricación y verificación;

- una ventaja competitiva en el mercado internacional.

Si además se utiliza el formato de la tabla anterior en A3 o incluso A2 se obtendrá:

- una manejo más rápido y eficaz de las normas.

- una accesibilidad a la información relevante.

- una facilidad en la programación de la obtención de las tolerancias.

Referencias

- Manual que Máquinas. Cálculo de taller de A. L. Casillas

- ISO/TR 14638:1995, Geometrical Product Specifications (GPS) — Masterplan

- UNE EN ISO 286-1: 2010 Especificación geométrica de productos (GPS) – Sistema ISO para las tolerancias dimensionales - Parte 1: Base de tolerancias, desviaciones y ajustes

- UNE EN ISO 286-2: 2010 Especificación geométrica de productos (GPS) – Sistema ISO para las tolerancias dimensionales - Parte 2: Tablas de las clases de tolerancia normalizadas y desviaciones límite para agujeros y ejes.