Matrices de conformado para el futuro con aceros del último generación

17 de diciembre de 2010

Trabajando en un ambiente automatizado la fiabilidad de las matrices es esencial, los aceros usados en las matrices son por naturaleza muy frágiles, y el riesgo de aparición de fisuras es elevado. Estos aceros provienen de un mercado global siendo suministrados bajo una norma que define una composición química muy poco detallada, sin conocer el fabricante y su control de calidad, es imposible poder confiar en el rendimiento del acero.

Pretratamiento con nitruración

Se ha visto que la manera de fabricar las matrices puede mejorarse. El temple y revenido necesario para conseguir una resistencia mecánica suficiente implica pérdidas de tiempo y hace necesario mecanizar las piezas después del temple. La empresa Construcciones Mecánicas de Galicia (Comegal), conocedora de estos problemas ha modificado su manera de fabricar sus matrices. En las partes de la matriz donde se necesita aceros de alta resistencia mecánica, Comegal emplea aceros ya pretratados a diferentes durezas según las necesidades mecánicas. Es común emplear nitruración u otros tratamientos superficiales como PVD.

Con esta forma de trabajar los problemas de deformaciones y la mecanización después del temple se evitan. La baja temperatura a la que se realiza la nitruración no afecta las propiedades del acero como pasa en un temple y revenido tradicional. Otro efecto positivo de la nitruración es que se mejora la superficie de la matriz mejorando las condiciones de fricción. Como acero pretratado, Comegal utiliza con más frecuencia el acero Toolox, fabricado en la empresa siderúrgica sueca SSAB.

SSAB es una destacada compañía especialista en aceros de alta resistencia mecánica utilizado en aplicaciones de alta responsabilidad. La compañía realiza un control de calidad en cada una de las chapas fabricadas en Toolox. Después del tratamiento térmico, se hace un control de ultrasonidos y se garantiza su dureza, resiliencia y sus características de mecanizado y homogeneidad. Se trata de una diferencia frente a los aceros tradicionales, que normalmente se suministran bajo una especificación química. Además del control de calidad único, Toolox tiene ventajas técnicas como una mayor facilidad para mecanizar, nivel de inclusiones muy bajos y un nivel de tensiones residuales mínimo.

Comegal utiliza estas ventajas en sus matrices. Como confirma Emilio, jefe de taller de Comegal: “Hemos visto que el desgaste de nuestras herramientas ha bajado de una forma significativa, alrededor de un 30%. Además la superficie de las piezas es muy importante para nuestros clientes, sobre todo en la deformación de chapas de inoxidable. Hemos podido conseguir acabados de muy alta calidad en las piezas que hemos fabricado en Toolox”. Comegal utiliza Toolox para matrices de estampado tanto de aluminio como de acero aleado e inoxidable.

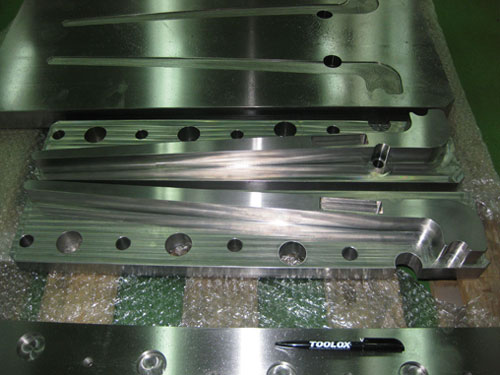

En las imágenes, se puede ver un ejemplo de una matriz hecha íntegramente de Toolox 33 con un tratamiento de carbonitruración. Las piezas con forma han sido cortadas mediante plasma, una manera mucho más eficaz comparando con la alternativa de mecanizarlo de una pieza cuadrada. En la matriz se conforman chapas de 1.5 milímetros de aluminio. La velocidad de fabricación no es muy elevada, con un tiempo de fabricación alrededor de 20 a 30 segundos por pieza, pero la matriz tenía que ser fabricada con toda urgencia, lo que hace todavía más interesante trabajar con un pretratado como Toolox.

Para el suministro de los aceros Toolox, Comegal confía en el servicio de la empresa Industrias Trimar, distribuidor de aceros de la firma SSAB. Industrias Trimar presta servicios de corte por plasma, oxicorte, corte por agua y corte por sierra para este tipo de aceros.