The spacers of Spirol allow a manufacturer of hinges doubling its production

December 15, 2010

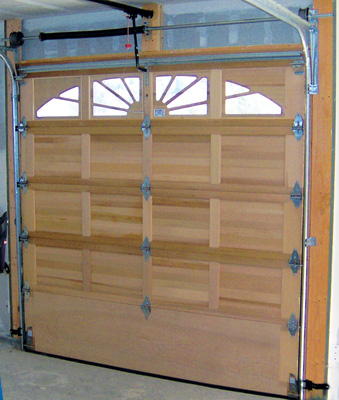

For years, the method of the manufacturer of the complete Assembly of a garage door hinge was profitable enough, with his production of 150 pieces per minute. But demand grew, and the employer had to make decisions. It was proposed to invest in new equipment for a cost of 15,000 euros. The option to buy another press to absorb the increase in volume was also considered, but in addition to the cost of this new machine, there were problems of space to locate her.

At the same time the client received a visit from Spirol during which she was shown the standard range of caps rolados cold. Immediately it was launched a review of engineering of application to determine if our 'lower cost solution' would work.

The solution, change of caps

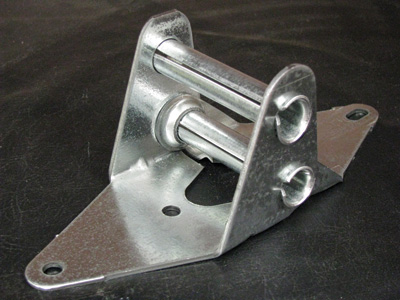

After testing and reviewing the implementation, recommended shell was one of the 30,000 standard products of the catalogue of Spirol. Using its technology of rolling cold, the pace of production now exceeds 300 caps per minute. This is equivalent to twice the client, so the piece price was much more under the pieces made by themselves. To change to the spacer standards, the customer had pieces of stock, it benefited from prices of raw materials in high volumes and without need for investment in its own process of manufacture of caps.

The savings generated by Spirol comes from the own process of rolling cold as steel strapping without any loss of material or shavings. The Department of engineering of Spirol carries more 60 years of working with customers to identify efficient, effective solutions and at the lowest cost.

The spacers Spirol gp100 of normal wall and thick wall SP150 series are used as separators, bushings of estrangement, shirts, sleeves, bushes, axles and pins. They replace cut pipes, clamps, rings and more expensive (machined) machined parts. The application more common is to use the spacers to separate two components. The ensemble is joined by a passant screw through the inner diameter of the spacer. SPIROL also has special spacers, which are manufactured to meet special requirements. They include shirts and sleeves of tension, very short spacer, tubular rivets and connectors.