Invertir en personal y maquinaria, la fórmula de éxito de Moldes J. Cereza

11 de noviembre de 2010

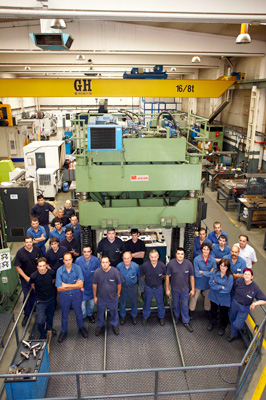

Es una empresa familiar formada por un equipo de 30 profesionales que en la actualidad es capaz de ofrecer a sus clientes un producto de muy alta calidad pero también la posibilidad de asesoramientos técnicos en todo lo que rodea al molde y a la pieza, ofrece estudios Moldflow de simulación de llenado, estudios de factibilidad, rediseños de pieza, ingeniería inversa, fabricación de moldes prototipos, desarrollo y fabricación de moldes de serie para inyección de plástico, inyección con gas, bi-materia, inyección con tela, fundición inyectada de aluminio o Zamak y moldes de soplado, puestas en marcha de producto en cualquier país del mundo y servicio postventa igualmente en cualquier lugar del mundo al que vayan nuestros moldes. Ofrecer un abanico de servicios lo más amplio posible es la única solución para competir hoy día con los países de bajo coste.

Dentro de una crisis como la actual, el sector del molde vive una situación extremadamente complicada pero que viene de muy atrás, de mucho antes que se empezase a hablar de recesión a nivel general. Al principio fueron los países del Este pero pronto se empezó a oír hablar de las posibilidades de China e India y de repente, sin tiempo para reaccionar, nuestros clientes apenas enviaban proyectos para ofertar. ¿Qué podíamos hacer en una empresa familiar dedicada al diseño y construcción de moldes (especialmente para la industria del automóvil)?. Pues marcharnos para ver cuál era la realidad de todos esos mercados a la vez que iniciábamos una dura y costosa (a todos los niveles) reorganización de toda nuestra empresa.

Como punto fuerte, basta decir que contábamos con una serie de factores a nuestro favor:

- un alto know-how.

- un parque de maquinaria moderno con lo último en tecnología y especialmente en lo que se refiere a diseño y mecanizado en cinco ejes y alta velocidad.

- la mayor parte de nuestras inversiones estaban amortizadas.

- una idea clara de por donde iba el mercado y de lo que significaba la globalización.

Por otra parte, nos decidimos a salir por todo el mundo y prospectar los países del Este, México, China e India como posibles proveedores del molde, o al menos de algunas de sus partes. Y, al mismo tiempo, hicimos una campaña comercial muy agresiva ampliando nuestra cartera de clientes recorriendo países como Francia, Alemania, Sudáfrica, Italia y algo de Estados Unidos, etc.

Tuvimos experiencias construyendo moldes en China, nos planteamos la posibilidad de instalarnos allí con un taller ‘propio’ (contando que no hay nada propio en aquel país) y también nos planteamos algún tipo de acuerdo estilo ‘joint-venture’. Pero finalmente, y tras ver los costes de un producto como el que Moldes J. Cereza elabora, con las mismas especificaciones, calidades y resultados productivos, decidimos que teníamos que jugárnosla, teníamos que apostar por un nuevo concepto de empresa, nuevas estrategias de trabajo y la tecnología más puntera disponible en el mercado.

En aquellos momentos, en los que cuando contabas al personal las dificultades del sector y lo complicado que era conseguir nuevos proyectos la gente dudaba de tu sinceridad y pensaba que lo que se querías era perjudicar su calidad de vida en el trabajo, tuvimos que decidir llevar a cabo una profunda reestructuración eliminando gastos y creando un nuevo equipo de profesionales que entendiese las necesidades de nuestros clientes, las necesidades de flexibilidad en el trabajo y que fuese consciente de los plazos más que ajustado y de los precios ínfimos que exigían hacer, en el mismo tiempo, muchos más moldes y más baratos.

Así conseguimos crear y consolidar el equipo que actualmente formamos Moldes J. Cereza que hasta el día de hoy ha sido capaz de plantar cara a los países emergentes.

En lo que a tecnología se refiere si hace ocho años introdujimos nuestra primera máquina de 5 ejes y alta velocidad (una Breton Matrix 800 con bancada de 2.500 x 2.000 x 1.500), hace tres años compramos una Hermle C40 con plato de 800 x 800 y este mismo año estamos instalando una FPT Roning con cambiador hasta 3 cabezales y 60 herramientas y dos bancadas, una fija y una rotativa que generan una superficie real de trabajo de 6 metros.

Al mismo tiempo, el personal de Moldes J. Cereza, de la mano de sus proveedores de software y herramientas, se ha preocupado mucho en desarrollar nuevas estrategias de mecanizado y numerosas pruebas con nuevas herramientas optimizando con ello los procesos y asegurando una continua innovación en el apartado de mecanizado.

Con ello hemos conseguido un mecanizado con unos acabados de altísima calidad, hemos conseguido acceder con herramienta a zonas que antes era impensable trabajar si no era con una erosión de penetración precisamente hemos reducido el trabajo de erosión más de un 85%, nos hemos evitado una enorme cantidad de horas de pulido y de ajustes ya sea de movimientos o de cierres generales de moldes.

La Breton Matrix 800 T2 es una máquina solo para acabados que, si se trabaja de la forma adecuada, con las herramientas y parámetros correctos, permite conseguir unos acabados realmente impresionantes. Esta equipada con un electromandrino capaz de girar a 24.000 rpm y girar en cinco ejes tanto de forma continua como en 3+2. La bancada es fija, lo cual permite apoyar todo el peso que se quiera y solo estás limitado para las dimensiones de la mesa (2.500 x 2.000).

Nuestra siguiente inversión en máquina herramienta fue una Hermle C40. Es una máquina que calificamos de alta productividad completamente distinta pero que se complementa muy bien con nuestro trabajo. Tiene una mesa rotativa (con 2 ejes en ella) de 800 x 800 que nos permite mecanizar piezas tales como correderas o movimientos inclinados en bloque o placas de figura siempre que entren en sus dimensiones. El cabezal es mecánico, con un alto par de potencia que permite una gran capacidad de arranque de viruta y hasta 18.000 rpm. Cuando necesitamos más vueltas para conseguir acabados de altísima precisión y calidad se activa el sistema de aire presurizado que, junto con multiplicadores almacenados en el cargador, nos permiten alcanzar velocidades continuas hasta 60.000 rpm. Esto nos permite empezar a mecanizar desde 0 con desbastes hasta la fase de acabado con fresas de hasta 0,3 milímetros de diámetro.

Nuestra inversión más reciente (instalada este mismo mes), es una FPT Roning. Una máquina con cambiador tanto de herramientas (hasta 60) como de cabezales (tres distintos), con 2 bancadas distintas pero complementarias, una fija de 4 metros y una rotativa de 2 x 2 metros que van a permitirnos trabajar tanto con una placa de grandes dimensiones como con varias placas más pequeñas puestas en escuadras especialmente diseñadas para ello.

La mesa rotativa nos va a permitir todavía más versatilidad permitiendo giros más allá de los 5 ejes que ya ofrece el cabezal de acabados y pudiendo llegar a un total de 7 ejes con la posibilidad añadida de realizar taladros profundos, algo que es también imprescindible en el tipo de molde que hacemos.

Esta inversión nos va a permitir acceder también a un tipo de trabajos que hasta ahora quedaban fuera de nuestro alcance por peso y dimensiones como moldes de pasoruedas, Ip Carriers, etc.

Hay quien dice que estamos locos pero la locura es quedarse quietos y no avanzar. Apostamos por el futuro, por el futuro de todos los que trabajamos aquí y, como todas las apuestas, a veces parece arriesgado

Y por último, pero no menos importante, está el proceso continuo de formación de nuestro personal y actualización de software de mecanizado. El equipo que forman los miembros del área de mecanizado dispone de equipos anexos a las máquinas para la elaboración de programas CAM mientras que las máquinas trabajan en automático pudiendo hacer formación in situ de aquellos que están en proceso de aprendizaje. El personal con conocimientos más avanzados recibe también formación por parte del proveedor de software en una sala especialmente habilitada para ello.

Es fundamental no solo que estar al día de las novedades y avances del sector, sino ir más allá y ser nosotros los que, viendo las necesidades que nos impone el mercado, seamos los que propongamos a nuestros proveedores los avances y mejoras que vamos a necesitar y vayamos así siempre un paso por delante.

A la hora de plantear una inversión como esta (de alrededor de 1’5 millones de euros) en medio de una situación como la actual las ideas que nos pasan por nuestra mente no son otras que las de seguir trabajando y apostando por el futuro. Queremos que nuestros clientes sigan depositando su confianza en nosotros, queremos poder ofrecerles precios y plazos que hagan que mercados de bajo coste como el chino no sean tan interesantes para ellos.

Quiero aprovechar para expresar mi agradecimiento personal y el de la familia a todo el equipo que forma Moldes J. Cereza y Prototipos y Útiles D. Cemar ya que con su interés, continuos esfuerzos y responsabilidad, hacen posible que nos superemos día a día y seamos capaces de hacer frente al momento que vivimos.