El cabezal de biselado automático, la revolución en la tecnología de corte

13 de octubre de 2010

A continuación se expone una breve historia de este tipo de elementos y sus características fundamentales.

Hace ya aproximadamente veinte años se empezó a comprobar las capacidades que los plasmas y láser podían aportar a la calderería y construcción metálica. Hoy en día, la tecnología plasma y láser ofrecen unas ventajas productivas claves y objetivas frente a otras tecnologías en el sector de la conformación metálica desde espesores finos (0,4 milímetros) hasta espesores medios (60 milímetros). Asimismo, la tecnología y equipamiento de las máquinas de corte se ha ido adaptando a las prestaciones actuales del plasma y del láser con el propósito de sacar el máximo aprovechamiento de estas tecnologías y hacer de máquinas de corte más flexibles y productivas.

Uno de los mayores avances en el campo de las máquinas de corte son, sin duda, los cabezales de corte biselado automáticos. Estos sistemas han representado posiblemente la mayor revolución tecnológica en las máquinas de corte actuales, permitiendo fabricar piezas con un nivel de acabado práctico e importantísimo. Actualmente, todas las empresas dedicadas a la construcción metálica están encontrando en estos cabezales la solución completa a los problemas de preparación de bordes para soldadura, reduciendo los costes de preparación de pieza de una forma asombrosa.

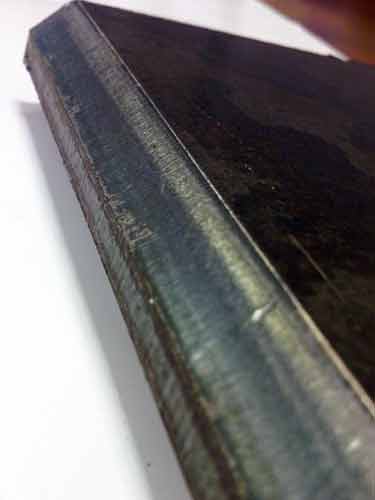

Prácticamente todas las piezas metálicas soldables desde 8 milímetros de espesor en adelante necesitan preparación de los bordes para ser soldadas de forma fiable y según normas. Hay que tener en cuenta que el rango de espesores más usual en calderería va desde 4 hasta 40 milímetros, con lo que la preparación de bordes se hace indispensable en el 90% de los trabajos. Esto se ha convertido en una necesidad global.

Los ángulos más utilizados hoy en día van desde 15º hasta 60º, aunque lo normal en todos los casos es preparar bordes con biseles entre 20 y 45º, dependiendo el tipo de trabajo y el sector. Hay que tener muy en cuenta que la capacidad del sistema de corte debe de dimensionarse en función del espesor y del ángulo que se requieran.

Existen varios tipos de cabezales de bisel para plasma y láser. Por una parte, están los clásicos cabezales giratorios compuestos de un eje angular y otro eje giratorio, los cuales han sido bastante usados en máquinas con controles numéricos tradicionales sin control a 5 ejes. Estos sistemas son mecánicamente bastante complejos y sobre todo muy voluminosos y de mantenimiento abundante y complejo. Una de las mayores limitaciones de funcionamiento de estos sistemas es la necesidad de ‘rebobinar’ el eje giratorio en los cambios de ángulo de las esquinas de la pieza, haciendo necesario la utilización de un amplio espacio entre piezas (de 20 a 50 milímetros) para poder hacer los cambios de ángulo.

Desde hace ya varios años, existen en el mercado cabezales denominados de segunda generación, basados en controles numéricos con funciones de 5 ejes.

En Tecoi hemos apostado por esta tecnología de corte en bisel por sus prestaciones y por su funcionalidad. Estos nuevos sistemas son la solución definitiva a los requerimientos de corte de los actuales trabajos de biselado y evitan todos los problemas y carencias de funcionamiento de los tradicionales cabezales giratorios. Los nuevos sistemas de 5 ejes, además de permitir giro infinito, no precisan de ningún tipo de mantenimiento de engrase ni limpieza. Además, no necesitan hacer bucles en las esquinas de las piezas en los cambios de ángulos con lo que el aprovechamiento de la chapa es inmensamente mayor.

Con los sistemas de biselado de 5 ejes se está cortando hoy en día con bancadas de corte en seco, bajo agua o cualquier sistema de bancada actual. Una de las mayores ventajas de este sistema es que no requiere una especialización del operario para hacer biseles, ya que la parametrización se realiza completamente desde el control numérico. Por otra parte, las dimensiones de estos cabezales son muy adecuadas para el corte con varios cabezales dentro de la misma chapa en fabricación de piezas pequeñas.

En la actualidad, para la tecnología láser y plasma, la solución de cabezal tipo robot o de 5 ejes es la más idónea dentro de un sector cada vez más exigente con la producción y la flexibilidad de la maquinaria.