GF AgieCharmilles exposes its vaccine anti-crisis: precision, quality and solutions

As a follow-up to special for those clients and colleagues who were unable to visit the Emo Milano 2009, GF AgieCharmilles organized its first International Technology Show (ITS) in its new Centre International of applications of Schorndorf, Germany. The event served to present in situ 15 GF AgieCharmilles machines in an innovative exhibition space occupied 1,400 square meters, as well as for the presentation of interesting examples of application of the machines from this manufacturer.

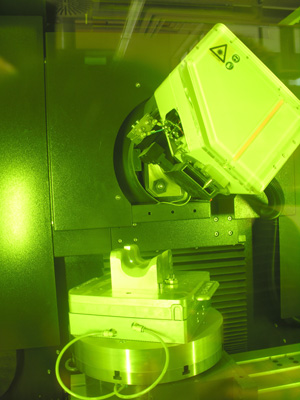

Laser ablation

One of the main and most striking developments of this company with headquarters in Switzerland is the 1,000 Ax of 3 and 5 axis Laser machine, aimed at the treatment of surfaces through ablation laser. It allows to approach complex surfaces and stands out for its ability to reproduce a surface as many times as necessary and to reduce production times. According to Bernhard Kasper, responsible for the company for Europe, "simultaneous 5-axis laser technology no offers it no other manufacturer".

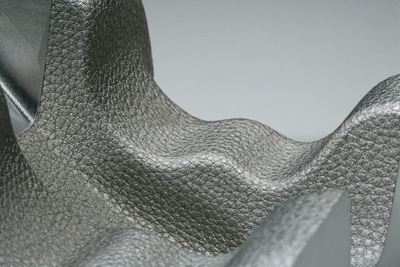

Laser ablation has been recently added to the supply of technologies offered by GF AgieCharmilles. It is used for etching, texturing, realization of microstructures, marking and labelling of geometries in 2D and even complex geometries in 3D. This technique facilitates the differentiation of the products on the market. Compared with conventional treatments of surfaces by means of chemical agents, the laser ablation is more economic, ecological and advantages of design.

Currently the range in this field consists of four machines, with solutions from the simplest Laser 500 in three axes to the 1200 Laser of 5 axes with runs of 1200 mm x 900 mm x 1200 mm (X)(, Y, Z) and maximum weight of piece of 1700 kilos. The maximum size of piece is 700 x 700 x 700 mm

EDM wire

Another new feature is part of a world in which GF AgieCharmilles moves like a fish in water: that of the eletroerosión. The model 1000 Cut OilTech, for machining ultraprecisos, has been built on the basis of a patented unibody which doubles its rigidity compared to normal buildings and provides an especially accurate rectangularidad of the two main axes X and and. The guides of the X axis and are separated, so that is not possible a mutual influence and anti-friction failures are not produced in the final parts of the routes of displacement.

His mechanical concept allows a perfectly homogeneous precision of ±1 μm in the entire work. You can work with two coils, each with a different thread (from 0.2 to 0.02 mm) type. It is a machine suitable for sectors like clockwork, electronic, medical and precision mechanical parts.

It is characterized also because usa oil as a dielectric, thus eliminating the corrosive effects of long periods of immersion of the piece. When machining is located on an automatic cycle of several pre-installed parts or machining processes carried out at night or on weekends, the pieces may remain submerged in the dielectric, which is why the intervention of the user to quickly remove the machined parts is unnecessary. In addition, with machining on oil is achieved a smaller distance between the wire and the piece, which translates into the possibility of obtaining internal minimum radii less than those obtained with water with same diameter of thread.

EDM by penetration

In EDM by penetration technology the latest news are models Form 2000 HP, Form 3000 H and Form 1000, all of them for production with very high demands. The Form 1000 is the newest, presented for the first time, designed for the micro-machining of precision and built on the patented unibody of the company. Allows machining of tools with less than 1 mm surfaces2, roughness of the final piece of Ra 0.05 μm and a minimum radius of 5 microns.

It incorporates the new ISPG generator that achieves speeds of erosion higher than the average of other products.

Precision machining

In this field the latest novelty is the Mikron HPM 400 U LP high speed machining center. It has been built in order to gain in precision and includes the revolutionary ITM system of measurement of the tool.

Intelligent measurement of the tool

The ITM (Intelligent Tool Measurement) system performs, without stopping production, a measurement of the tool extremely precise. In the words of Jens Thing, head of Marketing, "is a revolutionary system, which we have already presented at the EMO fair with a Heidenhain control and to add here in the Mikron HSM machining center 4000 LP". The repeatability of the measurement is between 1 and 2 microns and is around 50% more accurate than a laser system.

The Mikron HPM are equipped with modern technology of spindles, which focuses on vector control for all the times turning-point in the lower speed regime, accommodation of the hybrid spindle's ceramics of great stability, cooling of the shirt of the spindle through a regulated cycle coolant to achieve constant temperatures during all the work.

This series of machines are suitable for universal production of pieces of high quality with 3, 4 or 5 axes. More advanced heads (direct motor and spindle), the axes of rotation and inclination of direct drive and the robust body of machine facilitate economic and precise production.

Quality, price and solutions

Before a small group of European journalists, among them MetalUnivers / Interempresas, Bernhard Kasper, responsible for the company for Europe, referred to the significant fall of billing, around 40% in the first six months of the year. The descent is affecting equal to the business of EDM and milling and to a lesser extent serving customers. Except for China and Brazil, the descent is widespread. Nevertheless, it is convinced that "in Europe we have hit bottom and in the second half of 2010 I think that it will start improving." "Not before".

With the presentation of the new machine of laser ablation a next step could be the presentation of a hybrid machine. Kasper denied: "I do not believe in the hybrid machines, I do not think, as a whole, are economically viable for the client".

Asked about the keys to survive in these times noted the following: offer a distinctive technology, not to fight in the battle of the lower costs, accelerate the 'time to market'. And he said: "quality, price and response to a need are mandatory factors when there is a technology".