Meusburger 'gives way to the steel' with hard metal tools

In Meuburger it works only with a steel of high quality. In the stocks of this family business they expect thousands of tonnes in the most diverse qualities to be converted into ultraprecisos products. The raw material is first submitted to an annealing of elimination of tensions in the Horn. To this end, dishes are heated up to nearly 600 ° C and then cooled slowly for 15 hours. The annealing of elimination of tensions is a Meusburger carried out for all the qualities of steel and which allows to minimize internal tensions.

Playmobil, one of the clients of Meusburger

The majority of the frames are intended for manufacturers of molds and plastic products in Germany followed by Austria, France, Switzerland and Italy. Among more than 5,000 customers of Meusburger is even Geobra Brandstätter GmbH & Co (Playmobil manufacturer), a company known for particularly focused his work on the quality and, as recognizes it openly the society itself, by meticulously selecting their suppliers. Ceratizit is a Meusburger customer and buys based dishes that are machined in his own workshop of construction tools.

In fact, Meusburger and Ceratizit have been working closely since more than three decades ago. The first successful results were obtained in the tools for turning. "Opted by many manufacturers of tools that we do not want to rely on a single supplier", explains Hubert Weber, technical director of Meusburger. "In the case of CTC 5235, however is an uncontested victory: not only failed to register an increase of 30% of the useful life but also of 20% of the speed of court".

CTC 5235 with a more extensive field of application

Initially the plates with HyperCoat coating of the CTC 5235 series were developed for the machining of stainless steels and alloys of high technology, as used in the manufacture of blades of turbines. "But there are also other materials where this product can be used with success," said Stefan Bailom, technical consultant and seller of Ceratizit. "The surprising results in Meusburger confirm this." "The scope has expanded significantly".

According to Weber, "during the machining of steel is important to seek the best possible quality with optimal profitability". As for the demands of working hard metal, it emphasizes that "both the supplied hard metal and its coating must present a constant quality in order to ensure a production without problems".

The quality is and should be the key that differentiates European moulds manufacturers and thus Weber sums it up: "tools for the plastics industry are increasingly more complex." This aspect is what allows the European mould makers to be clearly distinguished from the Asian market. "The quality requirements continue to increase, and that playing in our favor." Therefore, they rely on Ceratizit, who according to the technical director of Meusburger, "is a very innovative manufacturer of tools it can often offer the solution more economic (...)." "In my opinion, the strong points of Ceratizit are good assistance and technical advice".

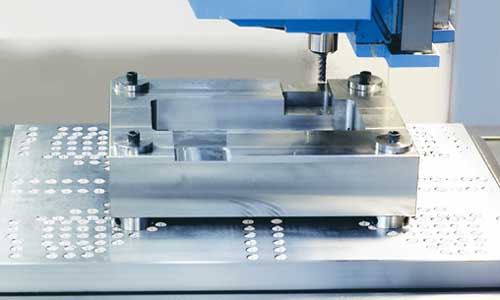

What is a rack?

The frames, also called portamoldes are used in the manufacture of plastic parts and are composed of several dishes of steel and different peripherals. Manufacturers of molds are cavities desired in these scenes (cavities in which acoplarán the imprints that are undergoing the impact of the molten material and have mechanized the negative of the figure to get) through milling and electro-erosión. The portamoldes consist of the plate on the side of the mouthpiece and the plate on the side ejector which can be separated and collected through elements of Guide (for example columns and sleeves). The two halves must fit perfectly including avoiding gap and to so close it completely.