Cómo aumentar la eficacia energética durante la soldadura

17 de julio de 2009

En clave de ahorro energético, para la soldadura no sólo son relevantes los datos característicos eléctricos del procedimiento, sino también la contemplación integral del proceso de producción. Ello incluye sobre todo los efectos de los pasos de trabajo anteriores y posteriores.

Tres aplicaciones típicas

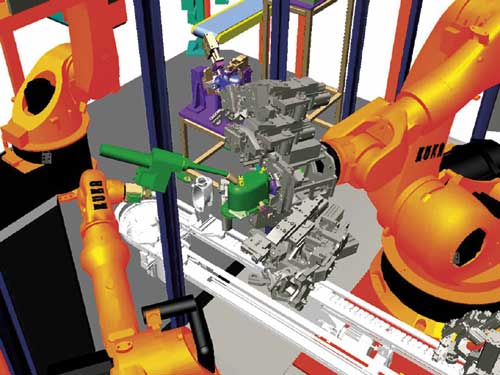

La soldadura robotizada rentable requiere un trabajo sin interrupciones. No obstante, los robots equipados con sistemas de soldadura MAG (gas activo de metal) convencionales tienen que interrumpir el proceso muy a menudo para limpiar los inyectores de las salpicaduras de soldadura. Aquí se pueden conseguir unos considerables ahorros en tiempo, energía y material, tal y como lo demuestra Ph. D. Yong joon Cho de Hyundai Motor Company. El cambio al procedimiento CMT no sólo aporta un número de salpicaduras de soldadura considerablemente menor, sino sobre todo una transición de metal más estable y una tendencia claramente inferior del electrodo de quedarse adherido. Solo ello reduce el tiempo de avería de las células de soldadura robotizadas en más de un 60% y al mismo tiempo, aumenta también la eficacia de la energía eléctrica utilizada.

Un puenteado de ranuras lo más elevado posible reduce los trabajos y costes para los pasos de producción anteriores, así como la fijación de las piezas a soldar. Según Heiko Steinmetz, el responsable de la planificación de producción, área de tecnología y conceptos, técnica de transformación, ensamblaje y montaje de Mercedes Benz, la soldadura LaserHybrid ofrece unas ventajas considerables para el empleo en grandes series. Frente a los procedimientos convencionales MIG o láser con alimentación de hilo frío, se consigue una velocidad de soldadura tres veces superior y un consumo de energía eléctrica claramente inferior, gracias a la reducida energía de estiramiento, y al mismo tiempo, una deformación térmica más reducida.

La soldadura por puntos convencional, especialmente en caso de piezas de aluminio, queda caracterizada por su elevado consumo de energía eléctrica y un alto desgaste de los electrodos. Las consecuencias son frecuentes interrupciones del proceso para cambiar los electrodos y unos costes más elevados para los electrodos. DeltaSpot es un sistema de soldadura por puntos con una cinta de proceso perimetral entre los electrodos y las chapas a ensamblar que protege los electrodos, pone a disposición el nuevo material en los puntos de contacto y reduce el consumo de energía. El proceso es flexible y controlable de forma universal, por lo que permite la soldadura por puntos continua con una calidad constante, de piezas de aluminio, diferentes calidades de acero, chapas galvanizadas y con un revestimiento orgánico. La demostrable calidad del producto y productividad superior de la instalación, los productos defectuosos claramente inferiores, así como el ahorro de energía y material conseguidos, dan lugar a una producción más eficaz y segura.