Tekla + Steel Projects + Ficep: el ‘dream team’ de la productividad

8 de junio de 2009

Todos los fabricantes de estructura metálica, sea cual sea su dimensión y capacidad, se encuentran a diario con problemas como desperdicio de material, excesiva manipulación de materiales, ineficiencia productiva, errores humanos o falta de comunicación entre oficina técnica y fabricación. Las tres empresas anfitrionas de las jornadas demostraron como, uniendo su tecnología, pueden proporcionar la optimización de cualquier proceso de producción de estructuras metálicas. Así lo demostraron Eric Beyer, Application Manager de Tekla, Wissam Dagher, Ingeniero Comercial de Steel Projects, y los representantes de Ficep: Patxi Xabier Blanco y Enrique Artaza, de Ficep Ibérica, S.A. y Giovanni Fioroni, de Ficep SpA.

Tekla Structures

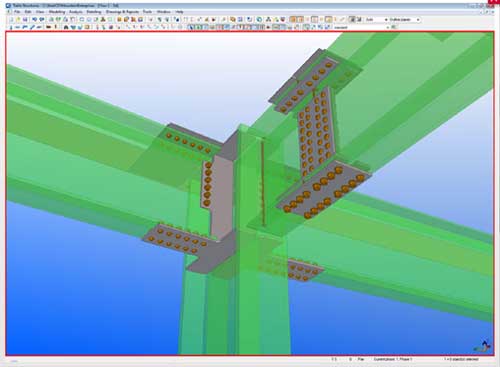

Tekla Corporation es una empresa internacional de origen finlandés que comercializa Tekla Structures, el software de modelado de información sobre construcción (BIM) para el sector del acero. Este software se integra completamente en todo el proceso de diseño estructural, desde el diseño conceptual al detalle, la fabricación y la construcción.

En la fase de diseño, Tekla Structures ofrece a los diseñadores herramientas flexibles para construir un modelo 3D detallado pensado para generar automáticamente bocetos e informes de montaje. Diseñar en un entorno 3D garantiza una colaboración exenta de errores durante las fases de fabricación y montaje. Además, todos los planos e informes se generan automáticamente a partir del modelo 3D detallado, por lo que siempre están actualizados. La configuración de este software hace posible que varios diseñadores trabajen al mismo tiempo en el mismo modelo.

Para el montaje, Tekla Structures incluye herramientas que detectan las posibles incoherencias en el diseño de la planta antes de proceder a las fases de fabricación y montaje. Asimismo, evita los costosos retrasos en el montaje. La coordinación y la planificación anticipadas garantizan que los trabajos de equipo y de fabricación llegan en la secuencia correcta.

Tekla + Steel Projects + Ficep= 4D

En las jornadas los ponentes de Tekla, Steel Projects y Ficep pudieron explicar cómo, desde un modelo Tekla, se puede importar de manera automática todo el proyecto de una obra en Steel Projects y más tarde descargar directamente todos los programas de trabajo a máquinas Ficep para que estas no sólo realicen los procesos habituales de corte o taladrado sino que además salgan todas las piezas con sus respectivos trazados y referencias para facilitar el posterior montaje.

El proceso empieza cuando se importa directamente desde el diseño 3D de Tekla (incluidos los trazados de marcado) al procesado de todas las piezas sin necesidad de programaciones adicionales. Los diferentes módulos de Steel Projects son los gestores de todos los datos del proyecto, siendo el vínculo directo entre la oficina técnica y la fabricación a pie de máquina. Toda la información del proceso se extrae del modelo de Tekla Structures y se importa directamente en la solución estándar WinSteel por medio de la aplicación que ha desarrollado Steel Projects mediante la Tekla Open API. Desde WinSteel, la información se transfiere directamente a las máquinas Ficep para procesar las piezas reales. Como remarcó Wissam Dagher, Ingeniero Comercial de Steel Projects, esta automatización limita al máximo los errores de producción y la aumenta reduciendo costes.

Una vez Steel Projects gestiona la información, realiza las oportunas órdenes de trabajo en ‘lenguaje máquina’ a las diferentes modelos de Ficep, para que éstas no sólo realicen los procesos habituales de corte o taladrado sino que además se obtengan todas las piezas con sus respectivos trazados y referencias para facilitar el posterior montaje. Y todo gracias a la gestión de archivos en formato XML. El estándar DSTV sólo describe dimensionalmente la pieza, mientras que el XML ofrece además los datos de qué y dónde, integrando los objetos en una realidad de conjunto. Mientras un diseño CAD puede ocupar hasta 100 megabytes de memoria, gracias al formato XML se puede obtener tener más información, mucho más completa y ocupando apenas 1 megabyte.

En el siguiente paso, todas las máquinas CNC de Ficep tienen la capacidad de informar de los tiempos reales de fabricación, estado y lista de producción pendiente. Steel Projects recoge toda la información de producción y pone en conocimiento de la oficina técnica, en tiempo real, el estado de proceso de todo el proyecto. Gracias a esta información, Tekla Structures puede representar en 3D el estado y la previsión del montaje, de nuevo en tiempo real. Como es fácilmente entendible, el gestionar varias obras de gran calibre no es una tarea fácil. Con la tecnología 4D gestionar múltiples proyectos es sencillo, eficiente y rentable. La gestión y el análisis de los costes (hora/máquina, hora/hombre, materiales, etc.) son cada vez más importantes en el día a día en un sector muy dependiente de la volatilidad de los precios del acero. Ello permite controlar todas las variables que hacen que un proyecto sea más o menos rentable para el estructurista. De esta manera se puede visualizar en tiempo real el estado de todos y cada uno de los procesos implicados en la finalización de un proyecto, pudiendo así subsanar posibles errores antes de que se produzcan y organizar con antelación todas las partes vinculadas a éste, sea cual sea su envergadura.

Las sinergias de todos los desarrollos llevados a cabo por los tres socios en cuestión, han confluido en el desarrollo de la tecnología 4D. Las máquinas no sólo obedecen órdenes, también ofrecen datos e informes en tiempo real. El flujo de información toma un sentido inverso: el software de diseño (Tekla) manda órdenes transformadas a lenguaje XML por el software de gestión (Steel Projects) a la máquina CNC (Ficep), que a su vez genera información que recoge Tekla con la que genera estimaciones del estado del proyecto.

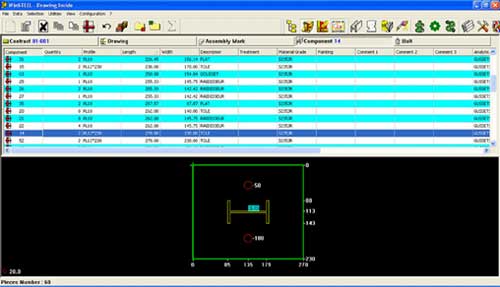

Steel Projects

Steel Projects es una empresa francesa especializada en sistemas de fabricación de acero integrados, CAM (fabricación asistida por ordenador) y MIS (sistema de información de fabricación) que ha desarrollado la interfaz entre Tekla Structures y WinSteel (sistema MIS). WinSteel es la configuración básica con la que se importa diferentes formatos y se transforma en 'lenguaje' Steel Projects. Esta aplicación recoge los datos para la creación de piezas de un diseño, plano o un pedido realizado manualmente. WinSteel se complementa con WinBar, para aprovisionamiento y ‘nesting’ de barras; WinCN, para gestión de máquinas CNC; WinSer, para la gestión de fabricación; WinNest, para ‘nesting’ de chapas; y WinPlan, de gestión de cargas en las máquinas. En configuraciones más completas, Steel Projects propone aplicaciones como SC_Stock, para gestión de almacén; SC_Prix de Revient, que administra obras; SC_Temps, para la gestión del tiempo por servicio, función y obra; SC_Achats, para administrar las compras; y SC_Devis/Metre, para la creación y seguimiento de presupuestos y mediciones.

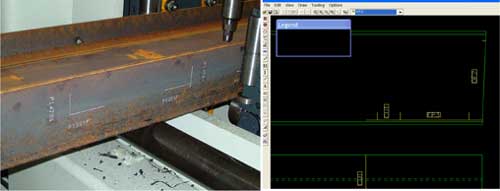

‘Scribing’, la clave del trazado

La introducción del proceso CNC del ‘scribing’ o trazado reduce los errores humanos en los procesos de diseño y montaje de la fabricación de acero, mejorando la automatización. Ficep ha incorporado a su gama de productos CNC este sistema de trazado de carburo de alta velocidad que permite trazar caracteres y líneas en la parte superior e inferior del alma, así como la en la cara exterior de las alas.

Antes, las marcas de pieza y la posición de los detalles se marcaban manualmente en función de la información obtenida de los planos de los talleres. Para aprovechar al máximo las ventajas de la tecnología de trazado, Steel Projects ha desarrollado una nueva aplicación capaz de extraer la información CNC directamente del modelo 3D de Tekla Structures y transferirla a las máquinas de fabricación del taller. La nueva Tekla Open API (siglas en inglés de ‘interfaz de programación de aplicaciones’) de Tekla Structures ha hecho posible realizar este avance. La aplicación no sólo extrae la información tradicional sobre perforación, taladrado, corte y copia que se utiliza en las extracciones de archivos CNC más comunes (como DSTV), sino que también introduce nueva información, como marcas de pieza de material detallado y ubicaciones de las piezas de material detallado sobre el material de las partes principales, referenciando absolutamente toda la pieza. Con la introducción de esta nueva interfaz y la tecnología de trazado de 4 lados, se incrementa considerablemente la eficiencia y la precisión del proceso de montaje del taller. Con el trazado, “la pieza se convierte en su propio mapa” como afirmó Patxi Xabier Blanco, director comercial de Ficep Ibérica.

Grupo Ficep

Situada en Varese (Italia), Ficep Spa. fabrica líneas e instalaciones automáticas de control numérico para los componentes estructurales de la construcción de acero, como edificios, puentes, naves industriales, torres eléctricas, etc. La filial española, Ficep Ibérica, S.A., comercializa y ofrece servicio posventa de las líneas automáticas fabricadas por el Grupo Ficep: líneas CNC de punzonado y corte de angulares; líneas CNC de punzonar, taladrar, oxicorte/plasma, para placas y chapas; y líneas de serrar, taladrar, desmembrar por oxicorte/plasma para vigas y perfiles.

Enrique Artaza presentó durante la jornada los nuevos desarrollos de Ficep, entre los que destaca un sistema único patentado por Ficep de carga y descarga con imán y un simulador completo de producción.