Development of a virtual machine for the dynamic analysis of machines-tool of big size

M. Sánchez, M. Armendia, J. Madariaga, I. Ruiz of Argandoña

IK4-Tekniker

02/12/2013IK4-Tekniker has developed a theoretical model in which engloban the dynamic capacities of the machines-tool, so much structural as of the accionamientos, and the effect of the configuration of the bows of control. This ‘Virtual Machine' allows to analyse the dynamic behaviour of the machine in his group being able to realizar the same essays that realizar in the tuned: positionings, ladders of position/speed, proofs of circumference, etc. In this work shows the validation of the model with two distinct applications. The ‘Virtual Machine' facilitates the realisation of an iterative process of design in which it can verify the effect of modifications of a simple way.

1. Introduction

Nowadays, the competition of the market globalizado requires reductions in the cost and in the time of development of the machines. Besides, the manufacturers of machine-tool no longer can allow the manufacture and essay of physical prototypes to be able to detect weak points and, in base to them, realizar the optimisation of the design. The globalisation of the markets has carried to these companies to specialise mainly in two families of products: special machines (mainly for the industry of the car) and big machines for the wind power or the aeronautical sector component manufacturing sector component manufacturing industry. Both families of products characterise because few times two machines are equal and, practically, realizar a new design in each machine produced.

In general, these machines have cinematic cartesiana and accionamientos with husillo of balls or pinion-zip. During the process of design is usual to realizar an analysis of Finite Elements employing a software like MSCNASTRAN and during this process is used to realizar the dynamic and static optimisation of the structural part of the machine. This analysis does not contemplate the interaction of the structure with the accionamiento/control, and to design machines with big bandwidth, generally required in the industry of automotive sector, is necessary to take into account said relation. Another of the fields where is necessary to take into account this interaction is in the field of the machines of big size where the strengths of cut can be of big magnitude and the machines can see affected by problems of chatter. By all this, is important to analyse the amortiguamiento that can give the system of control to each way of vibration, by what, is necessary to realizar a complete model of the machine where take into account of conjoint form so much the control, like the accionamientos and the structure. This type of model knows like virtual machine [1].

IK4-Tekniker has developed a theoretical model that simulates jointly the dynamics of the structure, accionamientos and bows of control of a machine-tool. Firstly it describes the model realizar and, next, will validate by means of two different applications.

2. Description of the model

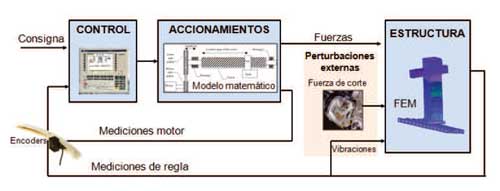

The Figure 1 sample a diagram of the model realizar integrating the control the accionamientos and the structure of the machine to analyse. The model has integrated in some surroundings Matlab/Simulink. To analyse the theoretical behaviour of a machine can study his answer in front of one consigns and/or in front of external perturbations (strengths of cutting and friction). In the case to want to analyse the behaviour of the machine in front of a real path, can obtain the same from files of code G and feed the model with her. To continuation describes each block of the model separately.

2.1 Control

The block of control designed contains the usual bows in applications motion control: a bow of proportional position (P) and a bow of speed provides-integral (PI). The bow of current considers ideal. In addition to this, exists the possibility to activate the feedforward so much of speed as of acceleration. This is a general algorithm, however, exists the possibility to adapt it to special cases. The exit of this block is the pair of the engine that enters in the block of accionamiento.

2.2 Accionamientos

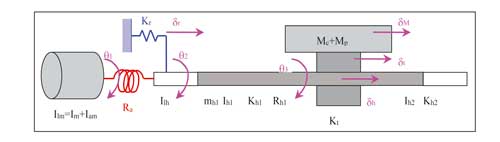

Employ some dynamic models of several degrees of freedom for the accionamientos developed by IK4-Tekniker [2]. They exist models for the three types of accionamientos more usual: husillo giratorio, nut giratoria and pinion-zip. These have realizar employing models of parameters concentrated, where obtains the matrices of mass and rigidity from the equations of power or Lagrangian. The data of entrance of these models will be the geometries, masses, inertias and rigidities of the elements of the accionamiento (almost all the data obtain of the catalogues). With the matrices of mass [M] and rigidity [K] obtains a system of space been that it implements in the global model. Like example, in the following figure can observe the degrees of freedom that have considered in the case of the husillo giratorio. To this block arrives him the signal of exit of the block of control (Pair of the engine) and obtain the strengths transmitted to the structure.

2.3 Structure

The structural part modeliza using the results obtained in the calculation realizar by means of finite elements (MEF), in the points of interaction with the block of accionamientos, in which they do the measures to feed the control and in the rest of points of interest as, for example, tip of tool. This last analysis is not possible in a real machine without employing specific material. The entrances of this block are the strengths generated in the block of accionamientos and the exit of this block are speeds and travel of the points that have taken into account in the structure.

3. Validation with experimental data

To continuation, go to analyse two cases in which it has applied the theoretical model and have realizar validations of the same by means of experimental measurements.

3.1 Example 1: Axis X of Fresadora of mobile bridge

The movement of the bridge of the fresadora studied realizar by means of a system Gantry composed by two accionamientos of pinion-zip (one in each column). The model developed integrates these two accionamientos (like this, as his corresponding controls) and a theoretical model of finite elements (MEF) of the structural part of the machine. The Figure 3 sample the diagram of Bode between the speed of the rule and the speed of the engine so much for the theoretical case like the experimental. The model developed attracts the three main ways of correct way. In the Figure 4 show the results when realizar the same positioning with the model and the real machine. The correlation between the results obtained with both systems is good. When employing the same configuration of control in the model and in the machine observes the excitation of the first way in both signals of pair. They exist some differences in the graphic of the pair engine that are achacables to errors of modelizado of the friction of the guides, that in this type of machines is used to to be important.

3.2 Example 2: Axis C of lathe

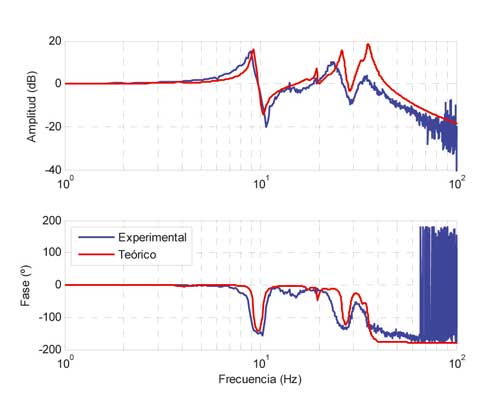

Has modelizado the behaviour of the axis C of a lathe of big dimensions (maximum size of piece Ø1.500x1.000 mm or Ø500x5.000 mm). In this case, it does not take into account the part of the structure of the machine, since it wants to centre in the dynamic behaviour of the axis C and east has a despicable influence in the structure. Like this, the model consists in a part of control and another of an accionamiento developed specifically in which modeliza the axis C, that consists in an engine that moves the dish/piece to través a reductor commercial and a train of gears, by means of parameters concentrated. To continuation compares the diagram of Bode of open bow between speed and pair engine, where observes the dynamics of the mechanical system (Figure 5to). In both cases observes with clarity the existence of a dominant way to 5,5/8,5 Hz. The theoretical model allowed to identify that this way came from of a flexibility located in one of the axles of the train of gears. When analysing the diagram of Bode in enclosed bow between speed engine and speed consigns (Figure 5b), where goes in at stake the bow of control, can observe that the result obtained with the theoretical model is very similar to the obtained of experimental form.

This type of models can be very useful since the cabezales every time have to bear pieces of greater size and with a model of this type can take into account the answer of the cabezal for different sizes of piece without having to mount them in machine. Like this, could define the rank of size piece that the machine will be able to move and the configuration of the bows of control so that his dynamic was acceptable.

4. Conclusions

Has presented a theoretical model to analyse dynamically machines-tools that engloba control, accionamientos and the structural part of the same. They have showed two applications in which the model retorts with fidelity the answer of the real machines modelizadas. The model allows to analyse the answer of machines in front of consign simple, like ladders or positionings, or more complex, like paths generated by means of code G. Also it can study the effect of strengths of perturbation, like efforts of cutting or friction.

This model allows the realisation of a process of design in which they can analyse the effect of the modifications in the dynamics without need to manufacture prototypes. Likewise, can study the dynamics of points that in the reality are not easy to measure but that they are of vital importance in the productive processes (tip of the tool). These advantages stress in big machines where the costs of prototyping and availability are especially restrictivos.

References

[1] Altintas And, Brecher C, Weck M, Witt S, T.To; “Virtual Machine tool”; In: Annals of the Cirp, Turkey, Aug, 21-27 TC M, 54/2/2005

[2] Egaña F, Ruiz I, Zatarain M, Azpeitia J, T.To; “Simulation of accionamientos in machine-tool and experimental validation”; In XIV Congress of MH, Technologies of Manufacture, Saint Sebastian, 2002, p 761