Precisión en una Micron Realm

La precisión de un sistema de medición láser se define por una parte por su repetibilidad, y por otra parte por la exactitud absoluta de la medición. Para el usuario, este último es el más importante ya que define el grado de precisión de las mediciones realizadas cuando se miden piezas de trabajo con características muy diversas. La razón de esto radica en el principio de funcionamiento del sistema. En pocas palabras, un sistema de medición láser utiliza una barrera de luz que funciona como un interruptor simple. Cuando una herramienta de rotación rompe el haz, se genera una señal de salto y se transmite al control para registrar posiciones de los ejes de la máquina. El software estándar integrado en el control de la máquina compara un valor de referencia calibrado respecto a los valores medidos de la herramienta y luego extrapola la longitud y radio de la herramienta, introduciendo estos valores de forma automática en la tabla de herramientas.

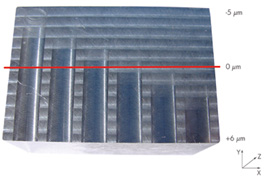

Para su preparación, un perfil escalonado se corta a lo largo del eje X. La diferencia de altura por cada paso es de 1 µm.

Independientemente del fabricante del láser, una señal de salto sólo se genera cuando un cierto porcentaje del haz de luz ha sido sombreado. Por esta razón, cuando se realizan mediciones de herramientas de características muy diferentes (por ejemplo, diámetro, forma, radio de corte, etc) el haz se sombrea de diferentes formas y puede dar lugar a imprecisiones, especialmente en sistemas láser con una óptica más simple. Al medir herramientas más pequeñas, es sobre todo la geometría del filo la que ejerce una mayor influencia sobre el resultado de la medición. Las diferentes geometrías de las herramientas de corte, sombrean el haz de diferente forma lo cual hace que se alcancen diferentes profundidades para cada herramienta cunado el láser envía la señal de salto al control CNC. Por esta razón, cuanto menor sea el diámetro del haz, menor será el error de medición creado por las diferentes geometrías de herramienta, pues un diámetro más pequeño del haz reduce al mínimo el error de sombreado para cada tipo de herramienta. Lo que esto significa en cuanto al proceso de mecanizado es que, cuando se utilizan diferentes herramientas, se crean desviaciones dimensionales en la pieza de trabajo. Los sistemas con diámetros de haz más grandes miden pequeñas herramientas como si fueran más largas de lo que son, porque la herramienta debe de entrar muy profundo en el haz para llegar al porcentaje de sombra necesario para mandar la señal de salto a control.

Haz del láser enfocado

Para contrarrestar esto, Blum-Novotest, utiliza una óptica de alta calidad sumamente precisa para poder enfocar el haz del láser. El enfoque genera un haz muy fino, con una intensidad de luz extremadamente homogénea, lo que garantiza una máxima precisión absoluta incluso para un abanico de herramientas muy amplio. Además, estos sistemas disponen de la patentada tecnología NT, que incorpora un microprocesador que identifican refrigerante y generan la señal de salto únicamente cuando el filo real ha tocado el haz del láser.

La pieza de trabajo es ranurada desde Y+ a Y- por el perfil escalonado con el fin de comprobar la precisión de posicionamiento de la máquina. En las máquinas de gama alta, la herramienta hace el primer contacto con la superficie de pieza exactamente en el lugar especificado por el usuario.

Procesos de Producción Fiables

Realmente, lo que cuenta en un proceso de mecanizado es la precisión obtenida en la pieza final, la cual se ve influenciada por un gran número de factores, cada uno de los cuales juega su papel. Las fluctuaciones de temperatura de la máquina y del entorno de la misma, el desgaste de la herramienta y los cambios en la longitud del husillo de la máquina a velocidades diferentes, todos ellos tienen un impacto directo en el resultado del mecanizado en un rango de centésimas de milímetro. Con los sistemas de medición láser, como LaserControl NT de Blum-Novotest, se puede comprobar con precisión la influencia de cada uno de estos factores. De todas formas, si la maquina en si no tiene una precisión de posicionamiento adecuado, incluso un sistema de medición láser más preciso tiene sus límites. Esa es la razón por la que Blum ofrece métodos y soluciones especialmente desarrollados. Esto nos permite probar la precisión de la máquina actual en una pieza y corroborar el nivel de precisión obtenido en las mediciones mediante láser Blum.

Comprobando la precisión de posicionamiento de la máquina

Para probar la precisión de posicionamiento de la máquina se ha empleado un perfil escalonado con escaleras de 1 micra y se ha mecanizado la pieza paralelo al eje X, tal y como se muestra en la Figura 1. La diferencia de altura de un paso a otro (en el eje Z) es de 1 micra. La precisión de posicionamiento se comprueba fresando ranuras a diferentes alturas distribuidas a lo largo del eje Y. Esto se hace varias veces, ajustando cada vez la profundidad de corte en 1 micra. Se emplea un microscopio para identificar el paso exacto donde se realizó el corte. Tal y como se muestra en la Figura 2, en una máquina excelente, se produce un corte uniforme y de perfil constante perpendicular a la dirección de corte. Esto le da al usuario información sobre la calidad de la precisión de posicionamiento de la máquina.

La precisión absoluta es la característica crucial para el usuario. En herramientas con características similares, el Blum LaserControl Nano NT alcanza una precisión de ± 0,5 micras.

Determinando la precisión absoluta

Existe la posibilidad de realizar otro tipo de ensayo para demostrar la precisión de un sistema de medición por láser. El requisito necesario para este tipo de prueba es haber testado anteriormente la precisión de la máquina. En esta prueba, varias piezas de trabajo de características muy diferentes (por ejemplo diámetro, forma de la herramienta) son medidas sin contacto mediante sistema de láser inmediatamente antes del proceso de corte. Una vez realizada la medición, se mecaniza en el centro de la estructura escalonada a una diemsion Z definida. (de Y + a Y-). Finalmente, mediante un microscopio se comprueban las profundidades micrométricas donde el primer corte de cada herramienta fue realizado. La posición del primer corte nos da la precisión micrométrica como respuesta a la pregunta de cómo de precisa ha sido mi medición. Si se aprecia una variación positiva, el valor obtenido en la medición es mayor a la longitud de herramienta y viceversa. La herramienta SF6 muestra la confirmación de que la línea cero de la herramienta corta la estructura escalonada.

Precisión absoluta a ± 0,5 µm

En el ensayo, se han medido 4 fresas cilíndricas (SF) y cuatro fresas de bola (KF) con un diámetro de 0,1 / 0,3 / 1 y 6 mm. Tal y como se aprecia en la Figura 3, cuando se utiliza un sistema de medición estándar mediante láser 'LaserControl Nano NT', la distorsión de los valores medidos (Figura 4) es de tan sólo ± 1 µm. Sin embargo, si ya es sabido antes de seleccionar el sistema láser que en la máquina se van a emplear solamente herramientas con características similares (por ejemplo, diámetro de la herramienta) (véase también la Figura 4: Herramientas SF1; SF0.1; SF0.3; KF1; KF0. 3; KF0.1), se puede aumentar la precisión absoluta hasta un rango de ± 0,5 micras.

Las pruebas se realizaron en un centro de mecanizado de alta gama bajo condiciones de mecanizado controlados.

Posibilidad de medir herramientas de hasta 5 µm de diámetro

El diámetro de la herramienta mínima que se puede medir, esencialmente depende de las condiciones en las que se utiliza el equipo. Los sistemas de medición Blum están diseñados de tal manera que garanticen una medición fiable y precisa, incluso en condiciones de mecanizado desfavorables, y para una amplia variedad de tipos de máquina. En el micro-mecanizado, hay diferentes condiciones que se pueden observar aparte de las vistas anteriormente. Por esta razón, Blum tiene disponibles dispositivos especialmente adaptados para diferentes tipos de tareas y entornos de medición. Si se necesita medir herramientas extremadamente pequeñas para aplicaciones especiales, Blum pre-configura los sistemas láser antes de ser entregados con la finalidad de satisfacer al máximo las necesidades del cliente.

En última instancia, el nivel de precisión obtenible siempre se reduce a una interacción entre el centro de mecanizado y el sistema de medición. Si se van a fabricar piezas de máxima precisión, por un lado se necesita de una máquina excelente y por otro lado, que el sistema de medición este posicionado y amarrado de forma que aporte una máxima precisión, eso sí, manteniendo la velocidad de giro de corte real del cabezal. Si se requiere precisión en un rango micrométrico, un sistema de medición láser de Blum es la única solución.