Herramientas de cerámica de alta velocidad

El óxido de aluminio (Al2O3), tiene una resistencia a la oxidación muy buena y una excelente vida de herramienta en el mecanizado continuo de alta velocidad de metales a base de hierro.

Por otra parte, el nitruro de silicio (Si3N4) tiene una alta resistencia a la fractura y resistencia a la oxidación. Es el mejor material para aplicaciones de desbaste en materiales a base de hierro. Las herramientas de corte de cerámica tienen una vida útil más larga y pueden alcanzar mayores niveles de productividad en comparación con herramientas de metal duro.

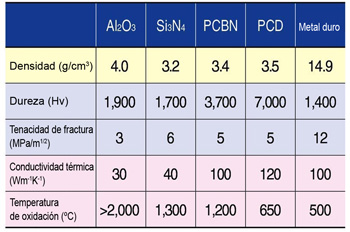

En la tabla 1 se muestran las propiedades mecánicas y térmicas de los diferentes materiales de las herramientas de corte.

El mejor trabajo para las herramientas de corte de cerámica

Sabemos que las herramientas de corte de cerámica se utilizan para cortar material extremadamente duro. El óxido de aluminio es bueno para el mecanizado de corte continuo de hierro fundido y del acero endurecido. El nitruro de silicio se utiliza para aplicaciones de desbaste en fundición y para aplicaciones de acabado de alta velocidad en aleaciones a base de Níquel.

1) Acero endurecido

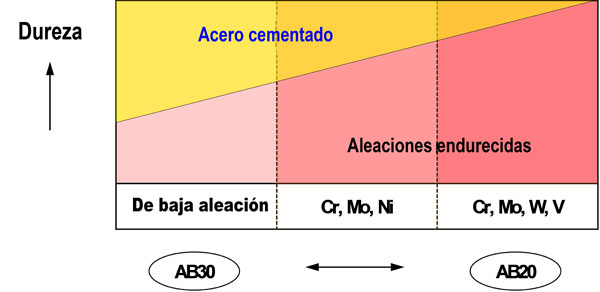

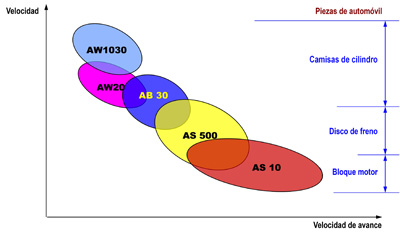

Las herramientas de óxido de aluminio son adecuadas para mecanizar acero endurecido debido a su excelente resistencia a la oxidación y estabilidad térmica. Taegutec tiene una gama de calidades de óxido de aluminio basadas en una mezcla de cerámicas para este tipo de aplicaciones. La calidad AB30 ha sido desarrollada para el mecanizado de acero templado en general, como el acero al carbono y acero de baja aleación (SCR, SCM). La AB20 es una excelente calidad de acero de alta aleación con gran dureza. La TB650 (CBN) se recomienda para el mecanizado de acero endurecido. El diagrama esquemático de la figura 1 muestra las calidades recomendadas de cerámica para varios tipos de aceros endurecidos.

La calidad AB20 es adecuada para el mecanizado de acero de alta dureza (CrMoNi) y acero para herramientas (SKD11) debido a su alta dureza y resistencia a la oxidación.

2) Fundición

En general, la cerámica es la mejor herramienta de corte para mecanizar fundición a alta velocidad, debido a su alta dureza y resistencia a la fractura moderada. La calidad de cerámica AW20 es buena para el corte continuo a alta velocidad de fundición. Tiene una excelente resistencia a la oxidación y estabilidad térmica en comparación con cualquier otra calidad de cerámica. El Nitruro de silicio a base de calidades de cerámica (AS500 o AS10) tiene una alta resistencia la fractura y una dureza moderada. Por esta razón, se recomienda este material para aplicaciones de desbaste en fundición tales como el torneado de discos de freno y el fresado de bloques cilíndricos. Las herramientas de cerámica proporcionan una mayor productividad y mayores ahorros en el coste comparado con las herramientas de carburo.

3) Súper-aleaciones

La cerámica es la selección ideal para velocidad de corte alta de materiales exóticos, especialmente las súper-aleaciones a base de Níquel. El material a mecanizar se utiliza ampliamente para piezas de la industria aeroespacial y es muy difícil de cortar. La calidad de Nitruro de Silicio (AS20) se recomienda para tornear a alta velocidad y para el fresado de Inconel 718. Tiene una alta resistencia a la fractura y una estabilidad térmica moderada.

Ventajas de utilizar herramientas de cerámica

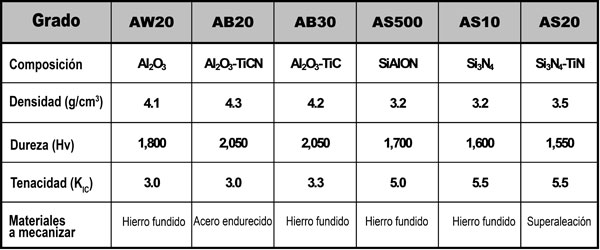

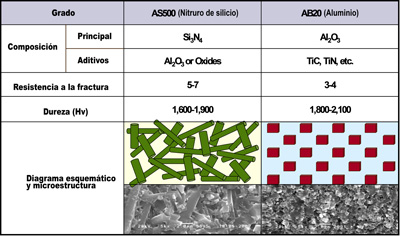

Como ya hemos mencionado, las calidades de cerámica tienen mejores propiedades físicas que las otras calidades. Las propiedades físicas de las calidades de cerámica de Taegutec se perciben en la tabla 2. En esta tabla se demuestra que las calidades de nitruro de silicio (AS10 y AS500) tienen mayor resistencia a la fractura, mientras que las calidades a base de óxido de aluminio tienen una mayor dureza. En la tabla 3 se demuestra la comparación entre el nitruro de silicio y las herramientas de óxido de aluminio a base de cerámica. Se muestra que el nitruro de silicio es más tenaz que el óxido de aluminio debido a su microestructura alargada, mientras que el óxido de aluminio es más duro debido a sus pequeños granos duros. Es por ello que se recomienda la calidad AS10 (o AS500) para el desbaste de materiales de hierro fundido, mientras que las calidades AW20, AB20 y AB30 son adecuadas para el corte continuo de metales a base de hierro.

1) Mecanizado de Alta Velocidad de camisas de cilindros

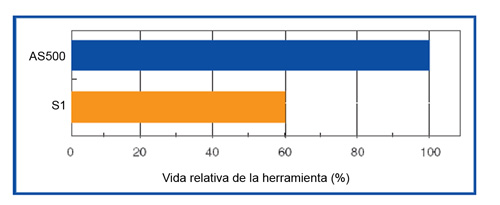

La calidad de Taegutec AW20 (o bien la AW1030 – calidad cerámica de óxido de aluminio con una capa recubierta de AlTiN), es una calidad muy buena para el mecanizado de alta velocidad de camisas de cilindros. Tiene una excelente resistencia al desgaste y una mayor vida de la herramienta que cualquier otra calidad de cerámica. Un ejemplo del éxito de esta aplicación se muestra en la figura 2. La vida de la herramienta de la AW1030 es casi el doble que la competencia, la calidad A1. La calidad de Taegutec AW1030 es una calidad pura de óxido de aluminio con una capa de recubrimiento PVD TiAlN y con un tratamiento especial del filo de corte. La excelente vida de la herramienta proviene de una combinación de su calidad y preparación del filo de corte. Está protegido por la patente PCT, PCT/KR06/05707.

2) Mecanizado de discos de freno

Recientemente hemos desarrollado la nueva calidad SiAlON (AS500) para el mecanizado de alta velocidad de los discos de freno. Tiene una alta dureza y alta resistencia a la fractura debido a su aleación, diseñada especialmente con tecnología de sinterización. Cuenta con una fuerte fiabilidad gracias al gran número de pruebas realizadas en el mercado global. La figura 3 muestra los patrones de desgaste de las plaquitas de cerámica después de mecanizar los discos de freno. La calidad AS500 tiene una vida de la herramienta 30% más larga que la herramienta de la competencia con las mismas condiciones de desgaste del flanco.

La larga vida de la herramienta se debe a su fase doble alfa / beta microestructura SiAlON. La fase Alfa SiAlON contribuye a la alta resistencia al desgaste y la fase beta contribuye a incrementar la resistencia a la fractura. Mecanizando discos de freno se puede garantizar mayor productividad que cualquier otra herramienta.

3) Rodillos de acero

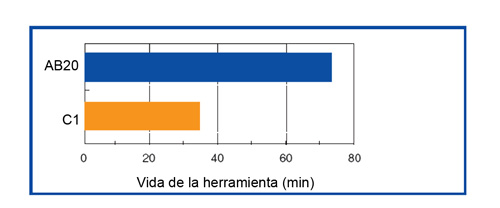

Las herramientas de corte de cerámica son una buena elección para mecanizados pesados de rodillos de acero con alta dureza, especialmente, acero rápido, acero cromado, rodillos de Níquel y rodillos adamite. La calidad AS500 se recomienda para aplicaciones de desbaste, mientras que la AB20 se recomienda, en torneado, para acabado de rodillos extremadamente duros. El ejemplo de torneado de desbaste de rodillo adamite se muestra en la figura 4. En esta se demuestra que la calidad de Taegutec AS500 tiene una vida útil de un 40% más que la calidad de la competencia (SiN) en el mercado coreano. El resultado de las prueba de torneado en acabado se muestra en la figura 5. La calidad AB20 tiene una excelente vida de la herramienta en aplicaciones de acabado de rodillos de acero a alta velocidad.

Conclusión

Taegutec produce herramientas de corte de cerámica únicas y de alta calidad para diversas aplicaciones tales como el mecanizado de alta velocidad de camisas de cilindros, y para rodillos de acero. La calidad AS500 de SiAlON se ha desarrollado para el mecanizado de alta velocidad de los discos de freno y para desbaste de rodillos de acero. La calidad AW1030 con recubrimiento PVD es una calidad excelente para el corte continuo de piezas de hierro gris y grafito compactado. Mientras que la calidad AB2010 recubierta en PVD tiene una vida de la herramienta más larga que las herramientas de cerámica mixtas de la competencia en el mecanizado de acero templado.

Taegutec se esfuerza por suministrar herramientas de cerámica únicas que sirven para aumentar la productividad y disminuir los costos de producción de nuestros clientes.