Estudio acerca de la tipología de las máquinas medidoras por coordenadas (MMC)

Las primeras MMC aparecieron a finales de la década de los años 50 del siglo XX y, actualmente, se han convertido en uno de los instrumentos de la metrología cuya presencia es fundamental en el departamento de calidad de la mayor parte de las empresas [Hansen et al, 1999]. Dichos equipos son capaces de ofrecer un control efectivo del proceso de fabricación de cualquier producto, caracterizado por una evaluación rápida y precisa de los aspectos dimensionales de éste [Carmignato et al, 2010].

Las MMC constan de dos partes principales: el palpador o sonda y el sistema que permite su movimiento por todo el volumen de medida del equipo. El palpador o sonda, que puede ser de contacto o sin contacto, recoge la información de la pieza y la envía a un ordenador donde, a través de un software, se pueden determinar tanto mediciones dimensionales (distancia entre elementos, posiciones, longitudes, ángulos, etc.) como desviaciones de la regularidad geométrica (errores de redondez, de planitud, de rectitud o de paralelismo, entre otros).

Tipología de las MMC

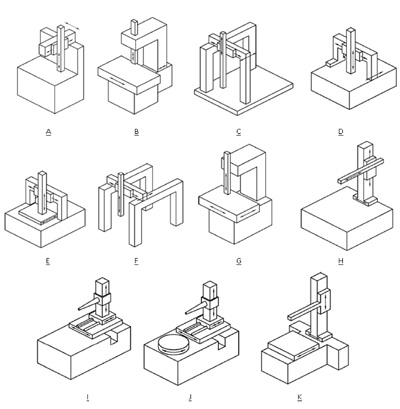

La arquitectura de una máquina medidora por coordenadas cambia dependiendo de varios parámetros entre los que se encuentran las direcciones de desplazamiento de sus componentes, cómo se realizan estos y su volumen de medición. La norma UNE-EN ISO 10360-1 realiza una clasificación de los distintos tipos (ver figura 1). Cada una de ellas cuenta con una serie de ventajas e inconvenientes que la harán más adecuada para unas aplicaciones determinadas en detrimento de otras para las que no será tan eficaz.

La primera de ellas es la máquina de cantilever [UNE-EN ISO 10360-1, 2001]. Consta de tres componentes móviles a lo largo de tres guías perpendiculares entre sí. El sistema de palpado va solidario con el primer componente, el cual se mueve verticalmente respecto al segundo y ambos se desplazan respecto al tercero horizontalmente. Éste, además, se mueve horizontalmente con respecto de la base de la máquina a través de unas guías y se encuentra apoyado en un solo extremo. Existen dos posibilidades de diseño: la de mesa fija, en la cual la pieza se sitúa sobre la base de la máquina, y la de mesa móvil, en la que la pieza va directamente colocada sobre el tercer componente.

Es un tipo de arquitectura que no se utiliza mucho actualmente y originalmente se aplicaba en máquinas medidoras por coordenadas manuales. Como la mesa de apoyo no incluye las guías de movimiento, se pueden medir piezas relativamente pesadas sin influir esto en la precisión de la medida. Al ser la parte móvil bastante ligera, es una máquina bastante ágil en modo manual y trabaja a altas velocidades en modo automático [Hocken et al, 2012].

El volumen de medida es largo en una dirección pero limitado en los otros dos ejes, por lo que es particularmente adecuada para medir piezas largas y delgadas. Además, al tener tres lados abiertos, posee una buena accesibilidad a todas las partes de la pieza [Dotson et al, 2003].

Como inconveniente, cabe destacar que al tomar medidas en el extremo del brazo de medida, la inclinación de éste puede provocar pequeñas variaciones en las medidas, lo cual debe ser corregido mediante el software de control de la máquina. Además, las frecuencias naturales del sistema son menores, lo cual limita el tamaño de la máquina [Hocken et al, 2012].

Una modificación de ésta es la de tipo puente en forma de L [UNE-EN ISO 10360-1, 2001]. En ella, el tercer componente se mueve horizontalmente sobre dos guías, una al nivel de la base y otra por encima de ésta, es decir, incorpora un soporte en el lado opuesto de la viga en cantilever. Como normalmente son adaptaciones de ésta, suelen tener velocidades de trabajo lentas y poseen bajas frecuencias de resonancia, lo que limita su tamaño [Hocken et al, 2012].

Otro tipo de máquina sería la MMC de puente móvil [UNE-EN ISO 10360-1, 2001]. Tiene tres componentes que se mueven a lo largo de guías perpendiculares entre sí y el sistema de palpado va solidario con el primero de ellos. Este primero, además, se mueve verticalmente respecto al segundo y juntos se mueven horizontalmente respecto al tercero. Este último se apoya sobre dos columnas, las cuales reposan en lados opuestos de la base de la máquina, y se mueve horizontalmente respecto a la base sobre la que se sitúa la pieza.

Es la más utilizada en la industria y sus volúmenes de medida varían desde los más pequeños, de 0,1 dm³, hasta los más grandes, de 8 m³, siendo éste el límite en el cual es posible realizar mediciones de una forma eficiente. Se pueden medir piezas con un rango de tamaños pequeño-medio y da lugar a valores de incertidumbre pequeños, siendo posible por lo tanto conseguir una gran precisión en la medida [Hocken et al, 2012]. Además, el movimiento de los ejes puede ser manual o automático.

La ventaja de este tipo de MMC con respecto del anterior es que las imprecisiones debidas a la existencia de un único brazo desaparecen al contar, en este caso, con dos [Hocken et al, 2012]. Sin embargo, al existir una columna a cada lado, podrían originarse problemas de accesibilidad de la sonda dependiendo del tipo de piezas que se deseen medir.

En la Figura 2 se muestra una imagen de la máquina medidora por coordenadas perteneciente a la Universidad Pública de Navarra (UPNA). Dicha máquina, que es de puente móvil, es una DEA Global Image Clima con cabezal articulado del tipo PH10MQ. El programa de medición que emplea es PC-DMISTM 3.7, que es uno de los más extendidos y populares dentro del campo de las máquinas medidoras por coordenadas. La incertidumbre específica (u) de la máquina viene dada por la siguiente expresión: u = (1,7 + 3·L/1.000) µm, donde L representa la longitud que se desea evaluar. Asimismo, su volumen de medida viene dado por: 850 mm (X) x 1460 mm (Y) x 780 mm (Z).

Una variación de este tipo de máquina sería la de puente fijo [UNE-EN ISO 10360-1, 2001], en la que el puente permanece rígidamente unido al resto de la máquina y es la mesa en la que se sitúan las piezas la que proporciona un grado de libertad, ya que se mueve horizontalmente con respecto del puente.

Esta estructura rígida hace que sea la MMC de mayor precisión y se suele utilizar en la calibración de patrones [Dotson et al, 2003]. Sin embargo, su rendimiento no es muy bueno ya que su velocidad de trabajo se ve reducida por el hecho de que la mesa móvil tiene un peso bastante elevado [Hocken et al, 2012].

Un cuarto tipo de máquina es la de tipo pórtico o gantry. Según la norma UNE-EN ISO 10360-1, se encuentra compuesta por tres componentes que se mueven a lo largo de guías perpendiculares entre sí, estando el sistema de palpado fijo al primer componente, el cual se encuentra posicionado y se mueve verticalmente respecto al segundo. El conjunto del primero y del segundo se mueven horizontalmente respecto al tercero y éste se mueve horizontalmente sobre dos raíles encajados en la base de la máquina, uno a cada lado de ésta.

Es la máquina de mayor volumen de medida ya que puede llegar hasta 100 m3, o incluso hasta volúmenes bastante superiores al anterior, y se utiliza para realizar mediciones precisas en piezas muy grandes, tales como motores, vehículos o componentes de estructuras aeroespaciales [Dotson et al, 2003].

Otra ventaja es que su arquitectura permite un acceso libre a todas las partes del volumen de medida. Además, el hecho de que únicamente la viga horizontal se mueva hace que la precisión sea bastante aceptable, incluso para las más grandes. La configuración básica suele ser relativamente económica pero si se requieren características especiales que aumenten la precisión, los costes pueden verse incrementados de manera importante [Hocken et al, 2012].

El siguiente tipo de máquina sería la de columna [UNE-EN ISO 10360-1, 2001]. El movimiento horizontal se realiza mediante la mesa en la que se sitúa la pieza y el sistema de palpado se desplaza verticalmente sobre una columna fija. Esta configuración puede dar lugar a un gran precisión pero al tener una estructura con forma de C, puede verse afectada por variaciones térmicas. Esto hace que sean utilizadas en ambientes especialmente acondicionados, es decir, sin grandes gradientes térmicos, tales como laboratorios de metrología y no tanto en entornos productivos [Dotson et al, 2003].

Finalmente, el último tipo de MMC que se contempla en esta clasificación sería la de brazo horizontal [UNE-EN ISO 10360-1, 2001] que, a su vez, puede contar con diferentes configuraciones: con cabezal móvil, con mesa fija, con mesa fija y plato giratorio o con mesa móvil, entre otras.

La primera de ellas, de cabezal móvil, está compuesta por tres componentes que se mueven a lo largo de guías perpendiculares entre sí. El sistema de palpado va fijo al primer componente y se mueve horizontalmente respecto al segundo. Ambos se mueven verticalmente respecto al tercero que se mueve también horizontalmente con respecto a la base de la máquina donde se sitúa la pieza. En la de mesa fija, la diferencia es que el primer componente sólo se apoya en el segundo componente en un extremo en disposición tipo cantilever. La de mesa fija y plato giratorio es similar pero incorpora un plato giratorio en la mesa de la máquina y, sobre éste, se coloca la pieza que se quiere medir. Finalmente, la de mesa móvil es similar pero la pieza se sitúa directamente sobre el tercer componente.

Todas ellas tienen como ventaja su excelente accesibilidad a todas las partes de la pieza que se desea medir y su alta velocidad de trabajo, lo que las hace adecuadas para su uso en el sector de la automoción, por ejemplo, a la hora de medir carrocerías o motores. Por el contrario, la precisión se ve un poco afectada por la falta de rigidez de sus componentes, lo que obliga muchas veces a compensar las posibles variaciones mediante el software de control de la máquina. Su brazo móvil puede llegar a tener un campo de medida de hasta 25 m [Hocken et al, 2012].

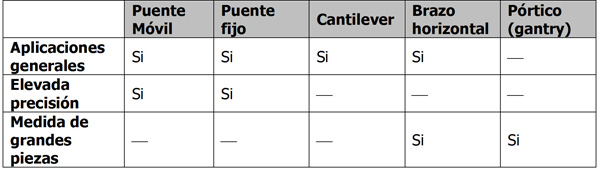

En la tabla 1 se muestra un resumen con las configuraciones de MMC más empleadas, comparando algunas de sus características metrológicas más importantes.

Tipos de sondas

Las mediciones en las máquinas medidoras por coordenadas se realizan a través de la sonda, que es la parte móvil y que se desplaza en las direcciones de los ejes por todo el volumen de medida de la máquina. La norma UNE-EN ISO 10360-1 la denomina de una forma más técnica como sistema de palpado. Su misión es tomar las coordenadas (X, Y, Z) de puntos concretos de la pieza para que, de esta forma, el software asociado a la máquina pueda obtener las mediciones necesarias.

La sonda o sistema de palpado es la base del funcionamiento de la MMC. Actualmente, se encuentran disponibles en el mercado una gran variedad de sistemas y, aunque suelen ser compatibles con la mayor parte de las máquinas, cada usuario debería determinar cuál es el que mejor se ajusta a sus necesidades concretas.

Existen dos tipos fundamentales de sondas: las de contacto y las de no contacto. Como su propio nombre indica, las primeras tocan físicamente la pieza y, a su vez, se pueden clasificar en sondas fijas, sondas de palpado punto a punto o sondas de palpado continuo (‘scanning’).

Las sondas fijas se utilizan en MMC manuales ya que el operario pone en contacto, manualmente, la sonda con la pieza en la posición que más convenga, espera a que la MMC se estabilice y es él mismo quién ordena a ésta registrar su posición. Existen en gran variedad de configuraciones y se utilizan actualmente para medir superficies curvas, distancias entre elementos, ángulos y diámetros de ejes o de agujeros en aplicaciones que no requieran de gran precisión. El inconveniente que pueden tener es que, al ser manejadas directamente por el operador, su repetibilidad no puede asegurarse si hay un cambio de operador, apareciendo posibles inconsistencias en las medidas.

Las sondas de palpado punto a punto (también llamadas sondas de disparo por contacto) obtienen diferentes puntos sobre la pieza de forma discreta y son las más utilizadas actualmente. Cada vez que la punta de la sonda entra en contacto con la pieza, se genera una señal electrónica de forma que las coordenadas de la posición de ésta en ese momento quedan registradas. Pueden ser manejadas manualmente o automáticamente y cuentan con una gran variedad de cabezales y accesorios, lo que les da una gran versatilidad. Además, eliminan la influencia del operario en las mediciones. Los posibles errores provocados por flexión de la punta de la sonda o por diferentes sensibilidades de ésta, según el ángulo de contacto con la pieza, se subsanan mediante la aplicación de sensores piezoeléctricos o galgas extensométricas, respectivamente, para conseguir precisiones por debajo de un micrómetro.

A modo de ejemplo, en la gigura 3 se muestra una sonda de contacto punto a punto de la marca Renishaw. La sonda de contacto, que es una de las disponibles en la MMC de la UPNA, es una sonda modelo TP-200 y emplea en su fabricación la tecnología de galgas extensométricas. El conjunto vástago-punta del palpador presenta una unión de tipo magnética, lo que facilita un rápido cambio del mismo. En el caso de la figura 3, la longitud del vástago del palpador es de 20 milímetros y su punta es una esfera de rubí con diámetro de 3 milímetros.

El último tipo de sistemas de palpado de contacto son las sondas de palpado continuo (también conocidas como sondas de inspección), las cuales, aunque también pueden ser utilizadas como las anteriores para tomar puntos de manera discreta, su función principal es el registro continuo de las coordenadas de una serie de puntos de la superficie de la pieza cada segundo, determinando su forma y tamaño. Para conseguir esta elevada velocidad de registro de puntos, se requiere de software especial ya que los elementos geométricos que utilizan los programas tradicionales no son suficientes para generar trayectorias con el número de puntos necesario. Este tipo de sondas se utiliza para inspeccionar y medir con una gran precisión formas irregulares, tales como álabes de turbina o distintas partes de un automóvil. Además, pueden ser utilizadas en aplicaciones de ingeniería inversa.

El extremo de la sonda que entra en contacto con la superficie de la pieza, que se conoce con el nombre de punta del palpador, es generalmente una esfera de rubí sintético en lo que se conoce como palpadores rectos. Se utiliza como material de fabricación de la punta el rubí por su elevada dureza, lo que minimiza el desgaste, así como por su baja densidad, que hace que la masa de la punta sea más pequeña y, por lo tanto, que se reduzca la posibilidad de una detección errónea de un punto debido a las vibraciones de la máquina. Antes de comenzar a realizar las medidas con la MMC, se debe asegurar la ubicación y el diámetro de la esfera de la forma más precisa posible y, para ello, se utiliza una esfera calibrada de unos 30 milímetros de diámetro, generalmente fabricada de material cerámico, con la que la máquina puede determinar estos parámetros previos a cualquier medición.

En la figura 4 se presenta una sonda de contacto continuo también de la marca Renishaw. La que aparece en dicha figura es una del modelo SP-25. Lleva montado un conjunto vástago-punta con una longitud de 21 milímetros y una punta esférica de rubí de 5 milímetros de diámetro.

Además de palpadores rectos, existen otros tipos de palpadores cuyo uso es más específico como pueden ser: los palpadores en estrella utilizados para inspeccionar superficies diversas, palpadores de punta para inspeccionar agujeros pequeños o formas roscadas con precisión, palpadores con vástago de cerámica para agujeros y superficies profundas, palpadores de disco para muescas y estrías en diámetros interiores y palpadores cilíndricos para medir agujeros en láminas, los centros de éstos y superficies roscadas, entre otros.

El otro tipo de sondas que existe son las sondas de no contacto y que, normalmente, se suelen utilizar en aplicaciones donde la pieza sea flexible o de un material blando (por ejemplo, de espuma) y un contacto de la sonda pueda distorsionar la geometría de la propia pieza. Sin embargo, en la actualidad tienen menor precisión que las de contacto.

El primer tipo de sonda de no contacto es la sonda láser. Funciona igual que la sonda de disparo por contacto pero, en este caso, es un haz de láser que funciona como interruptor óptico y que interactúa con la superficie de la pieza. La sonda proyecta un haz de láser sobre la superficie de la pieza y, entonces, la posición de ésta se determina por triangulación en la lente que se encuentran en el receptor. Con este tipo de sondas pueden aparecer ciertos problemas como, por ejemplo, en la medida de superficies esféricas, si el haz se refleja en otra dirección que no sea la del detector de fotodiodo.

En la figura 5 se muestra la sonda láser disponible en la máquina medidora por coordenadas de la UPNA. En este caso, se trata de un modelo Metris LC-50 con un láser de clase 2 que presenta una incertidumbre de 15 μm y una velocidad de escaneado hasta 19.200 puntos/s con un paso de 0,1 milímetros.

El otro tipo de sondas de no contacto son las sondas de visión. Éstas no hacen una medición directa sino que obtienen una especie de ‘fotografía’ de la pieza, que se digitaliza y a partir de la cual se obtienen las dimensiones de la misma. Suelen ser rápidas y precisas y se utilizan fundamentalmente donde se requiera una inspección rápida de la pieza.

Software de medición

Una vez que la sonda lleva a cabo los contactos con la superficie de la pieza, la información recogida debe ser analizada a través de un software específico, de forma que sea traducida en un conjunto de elementos geométricos conocidos (tales como planos, esferas, círculos, etc.) por medio de modelos de ajuste que pueden ser más o menos complejos. Una vez realizadas estas aproximaciones a elementos geométricos, se podrán calcular diversos tipos de operaciones entre ellos (como, por ejemplo, intersecciones), posiciones, distancias entre elementos o errores geométricos de las piezas (tales como de redondez, de cilindricidad, de planitud, etc.).

Según la norma UNE-EN ISO 10360-1:2001, se define a un software de referencia como el que calcula los valores de parámetros de referencia así como los residuos de referencia del elemento gaussiano asociado a cada conjunto de datos, siendo dichos valores de referencia los valores numéricos de los parámetros empleados en la parametrización de referencia para un conjunto particular de datos de referencia.

En consecuencia, un software de medición comprende el conjunto de programas, procedimientos y documentación empleados para controlar una máquina medidora por coordenadas. La utilización de un buen programa de medición de la MMC asegura una buena precisión en las medidas, análisis estadísticos de alto nivel completados con bases de datos y, en definitiva, permite un control en tiempo real de la máquina. Por lo tanto, el desarrollo de software de medición adecuado en el caso de las MMCs es uno de los factores más importantes a la hora de explicar la importancia que han alcanzado éstas dentro del campo de la metrología industrial.

Como ya se mencionó anteriormente, el programa de medición que se utiliza en el caso concreto de la máquina de la Universidad Pública de Navarra es PC-DMISTM. Dicho software empleado está desarrollado por la empresa norteamericana Hexagon Metrology S.A. y da acceso, de una forma sencilla, a funciones de programación, evaluación y obtención de informes acerca de la pieza concreta que se está analizando.

PC-DMIS es, en general, el software utilizado en las máquinas medidoras por coordenadas fabricadas por Hexagon Metrology S.A. pero, además, puede ser utilizado en la mayoría de equipos de otros fabricantes. PC-DMIS aparece en diferentes versiones que cuentan con módulos opcionales, a fin de satisfacer los requerimientos específicos de cada usuario [PC-DMIS, 2012].

Por otro lado, PC-DMIS puede ser también ejecutado de forma ‘offline’, es decir, sin necesidad de conexión a la MMC, lo que permite generar los programas mientras la máquina sigue trabajando sobre otras piezas. Esto es muy útil en entornos de alta productividad, donde se debe optimizar el tiempo de trabajo de las MMCs.

MCOSMOS (cuyo acrónimo significa ‘Mitutoyo Controlled Open System for Modular Operation Support’) es otro software que se utiliza en el control de MMC. Está desarrollado por la empresa japonesa Mitutoyo S.A., dentro de su plataforma de soportes informáticos MiCAT (‘Mitutoyo Intelligent Computer Aided. Technology’) [MiCAT (Mitutoyo S.A.), 2003]. Permite el tratamiento de una gran cantidad de información de forma sencilla, transmitiéndola a través de todas las diversas áreas del entorno de producción. Cuenta con diferentes módulos instalables para satisfacer las necesidades específicas de cada cliente.

Calypso, desarrollado por la empresa alemana Carl Zeiss S.A., cuenta también, al igual que los dos anteriores, con diferentes módulos y versiones adaptadas a las necesidades del cliente [Calypso (Carl Zeiss S.A.), 2010].

Además de estos tres programas de medición para MMCs, que son los más extendidos y representativos, existen otros muchos más ya que la mayor parte de los fabricantes de máquinas medidoras por coordenadas suelen contar con su propio software desarrollado. Por tanto, lo más cómodo para el posible usuario es adquirir el software que mejor se adapte a sus necesidades al mismo tiempo que la máquina de medición de coordenadas.

Calibración

Como ya se ha mencionado, las máquinas medidoras por coordenadas se utilizan para medir todo tipo de geometrías complejas tanto en laboratorios de metrología como en las propias empresas. Sin embargo, su precisión en las medidas realizadas puede verse afectada con el tiempo debido a la aparición progresiva de ciertos errores en la MMC.

Existen 21 errores geométricos posibles entre los que se encuentran: los errores de desplazamiento lineal en cada uno de los ejes (3 en total), los errores de rectitud en una dirección debido al movimiento en otra (6 en total), los errores angulares con respecto de cada uno de los ejes (9 en total, donde cada uno de los tres posibles errores angulares recibe, en inglés, el nombre particular de ‘roll’, ‘pitch’ ó ‘yaw’) y, finalmente, los errores de cuadratura entre cada par de ejes (3 en total) [Hocken et al, 2012].

Además, el funcionamiento de una MMC se ve también afectado por su peso propio, el material del que está fabricada, sus años de servicio, las aceleraciones a las que se ve sometida, las vibraciones que pueden aparecer, el sistema de palpado, el controlador y el entorno en el que se encuentra ubicada [Agapiou et al, 2007].

Afortunadamente, los software de control actuales permiten compensar estos errores a partir de procedimientos periódicos de calibración, de forma que el operador de la máquina introduce la información necesaria en el software sobre cada error, es decir, cuánto se desvía cada medición de su valor real, y el software lo ajusta adecuadamente para futuras lecturas.

Según la norma UNE-EN ISO 10360-2:2010, que recoge los ensayos de aceptación y verificación periódica de máquinas de medición por coordenadas, existen diferentes tipos de procedimientos de calibración aunque todos ellos encaminados a asegurar la máxima precisión en las mediciones.

En primer lugar, existe un ensayo de aceptación que no es más que un conjunto de operaciones acordadas entre el fabricante y el usuario con el fin de verificar que las prestaciones de la máquina se cumplen.

En segundo lugar, se define un ensayo de verificación periódica de manera que, como su propio nombre indica, se verifique periódicamente (los fabricantes recomiendan una frecuencia, al menos, anual) que las prestaciones de la máquina siguen cumpliendo lo estipulado por el usuario. Este ensayo se lleva a cabo según los mismos procedimientos que los del ensayo de aceptación.

Además, para asegurar que se mantiene el nivel de confianza en las mediciones realizadas con la MMC, existe otro ensayo, denominado como control periódico, que es especificado por el usuario y que se lleva a cabo entre los ensayos de verificación periódica, con la frecuencia que el propio usuario estime necesaria.

El procedimiento de calibración viene definido en las diferentes partes de la norma UNE-EN ISO 10360 (1 a 6) y resumido en el Procedimiento DI-027 del Centro Español de Metrología (CEM) aunque existen otros procedimientos tales como el ASME B89 ó el VDI/VDE 2617. Todos ellos se basan en mediciones precisas de patrones previamente calibrados con una precisión superior a la de la máquina, para comprobar que las medidas entran dentro de unas tolerancias previamente definidas por el fabricante en el ensayo de aceptación. Sin embargo, difieren principalmente en el número y la forma de las comprobaciones que se deben realizar.

Además de estos procedimientos ya definidos, es recomendable el control periódico de la máquina, para lo cual, el usuario realiza las mediciones pertinentes ya conocidas de un instrumento determinado y comprueba que la máquina sigue ofreciendo el nivel de precisión requerido y no presenta errores importantes con una frecuencia bastante superior a la de los ensayos de verificación periódica (mensual o, incluso, semanal).

Los instrumentos que se utilizan son variados aunque todos deben contar con distancias conocidas fijas entre elementos geométricos sencillos de medir, ser mecánicamente robustos, tener un acabado superficial bueno para que no afecte a la medición y un coeficiente de dilatación térmica similar al de las piezas que habitualmente se midan con la máquina.

Entre los diferentes objetos que se utilizan destacan los platos y barras de bolas, los platos y barras de agujeros, artefactos circulares, piezas especialmente diseñadas (ver figura 6), cumpliendo las condiciones anteriores y que sean similares a las medidas realizadas habitualmente con la máquina, o incluso, sistemas láser. Aunque algunos de estos podrían ser utilizados en los ensayos de calibración periódica, normalmente se utilizan para asegurar un control de la máquina rutinario y sencillo para el usuario.

![Figura 6. Ejemplo de artefacto para MMC recogido en [Agapiou et al, 2007] Figura 6. Ejemplo de artefacto para MMC recogido en [Agapiou et al, 2007]](https://img.interempresas.net/fotos/778540.jpeg)

Por tanto, es totalmente recomendable seguir un control exhaustivo de las mediciones de la máquina ya que, si bien se trata de máquinas muy precisas y de extraordinaria fiabilidad, una pequeña variación en alguna parte del sistema de medición puede conducir a errores que deberían ser detectados a la mayor brevedad posible.

Resumen y conclusiones finales

En el presente trabajo se ha realizado un estudio acerca de la tipología más característica de las máquinas medidoras por coordenadas (MMC). Este tipo de equipos son utilizados en gran cantidad de aplicaciones industriales así como, en general, en el campo de la metrología, dado que éstas son capaces de obtener medidas con gran precisión dimensional. Asimismo, se han descrito los principales tipos de sondas más importantes que pueden llevar incorporadas, además de aspectos tales como los principales softwares de medición utilizados en las mismas así como el objeto de su calibración.

Referencias bibliográficas

[1] Agapiou, J.S.; Du, H., Assuring the day-to-day accuracy of coordinate measuring machines - A comparison of tools and procedures, Journal of Manufacturing Processes, Vol. 9 (2), 2007, pp. 109-120.

[2] CALYPSO (Carl Zeiss S.A.). http://www.zeiss.com/4125682000247242/

Contents-Frame/B9A995179F8F16728625789A00575334.

[3] Carmignato, S.; Voltan, A.; Savio, E., Metrological performance of optical coordinate measuring machines under industrial conditions, CIRP Annals - Manufacturing Technology, Vol. 59 (1), 2010, pp. 497-500.

[4] Dotson, C.; Harlow, R.; Thompson, R.L., Fundamentals of Dimensional Metrology, Ed. Thomson Delmar Learning, New York, 2003.

[5] Hansen, H.N.; De Chiffre, L., An industrial comparison of coordinate measuring machines in Scandinavia with focus on uncertainty statements, Precision Engineering, Vol. 23 (3), 1999, pp. 185-195.

[6] Hocken, R.J.; Pereira, P.H. (Editors), Coordinate Measuring Machines and Systems, Ed. CRC Press, Boca Raton, 2012.

[7] Leach, R.H., Fundamental Principles of Engineering Nanometrology, Ed. Elsevier, Oxford, 2010.

[8] MiCAT (Mitutoyo S.A.). http://www.mitutoyo.com/pdf/1701.pdf.

[9] PC-DMISTM (Hexagon Metrology S.A.). http://www.pcdmis.com.

[10] Procedimiento de Calibración DI-027: Medidores de Tres Coordenadas, Ed. Centro Español de Metrología (CEM), Madrid, 2003.

[11] UNE-EN ISO 10360-1: Especificación Geométrica de Productos (GPS). Ensayos de Aceptación y de Verificación Periódica de Máquinas de Medición por Coordenadas (MMC). Parte 1: Vocabulario (ISO 10360-1:2000), Ed. AENOR, Madrid, 2001.

[12] UNE-EN ISO 10360-2: Especificación Geométrica de Productos (GPS). Ensayos de Aceptación y de Verificación Periódica de Máquinas de Medición por Coordenadas (MMC). Parte 2: MMC Utilizadas para la Medición de Dimensiones Lineales (ISO 10360-2:2009), Ed. AENOR, Madrid, 2010.