iMachining: el CAM que reduce hasta el 70% el tiempo de mecanizado

20 años poniendo en valor ideas

Fundada en 1998, CimWorks está formada por profesionales con más de 25 años de experiencia en el área de la Informática Técnica. Ricardo Aguirreche, director de Desarrollo de Negocio del Grupo CimWorks, fue el encargado de presentar su compañía a los asistentes al seminario, formada mayoritariamente por ingenieros y diseñadores industriales. También estuvo presente Esteve Galindo, director general de esta empresa que desde 2001 pertenece al Grupo CDM, con base en Parma (Italia). Tras estos años de experiencia en la industria del CAD, CAM, CAE, PLM, CimWoks cuenta con más de 1.000 clientes. Aguirreche presumió que “16 años después, nuestros primeros 50 clientes hoy todavía lo siguen siendo”.

CimWorks fue el primer distribuidor de SolidWorks en España y con esa experiencia proporciona desde hace 10 años todos los productos y servicios de SolidWorks, el software de referencia en el mercado para diseño mecánico 3D. “Contamos con el mejor equipo y los mejores medios para realizar formación, consultoría, asistencia técnica y otros servicios requeridos por nuestros clientes”.

Aguirreche desgranó las cuatro áreas de negocio de CimWorks que cubren de forma integral los diferentes aspectos de la estrategia PLM de sus clientes: Consultoría Tecnológica; soluciones de creación de la Información de Producto; soluciones de Gestión de la Innovación y el Desarrollo de Productos; y Servicios Profesionales.

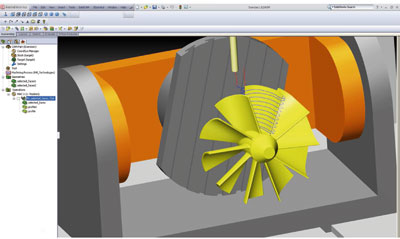

SolidCAM es la solución de CAM para SolidWorks, totalmente integrada, que cubre todas las aplicaciones CNC —fresado 2.5D, mecanizado de superficies de alta velocidad (HSS), mecanizado de alta velocidad (HSM), mecanizado indexado multicara (4/5 ejes), fresado 5 ejes simultáneos, torneado, fresado-torneado hasta 7 ejes, corte por hilo— y soporta todas las aplicaciones CNC de software de CAM, incluyendo 2.5D Fresa, 3D Fresa/HSM, Indexado y Fresa 4/5 ejes simultáneos, Torno, Fresa-Torno para máquinas CNC multitorreta y multihusillo y WireEDM (Hilo).

Esta revolucionaria tecnología iMachining de SolidCAM permite ahorrar hasta un 70% del tiempo de mecanizado CNC y prolonga la vida las herramientas entre 2 y 3 veces. Juan José Jiménez, responsable de Aplicaciones de CimWorks, llevó a cabo la presentación de iMachining, aplicación que lleva en el sector varios años, con más de 16.000 puestos instalados en todo el mundo, pero sin presencia en el mercado español.

Trayectorias revolucionarias

Muchos profesionales del mecanizado han tenido dificultades en los procesos de mecanizado de alta velocidad con sus programas CAM debido a la muy poca atención (o ninguna) a la necesidad del usuario para obtener ayuda en la decisión sobre las condiciones de corte adecuado o a la dependencia de los parámetros de condiciones de corte en el estado de la máquina-herramienta. Estos programas tampoco se ‘esforzaban’ en tratar de maximizar el área de corte por trayectorias en espiral, y la reducción de la zona de corte mediante trayectorias trocoidales o no le prestaban atención a las vibraciones y ruidos, y las posibles formas de reducirlos.

Para dar respuesta a estos contratiempos que se planteaban, SolidCAM decidió en 2006 desarrollar el primer producto que realmente satisficiera las expectativas del mecanizado de alta velocidad y proporcionara una solución óptima a estos problemas. Así nació iMachining, que con la particularidad de haber sido diseñado de cero, sin partir de ningún programa previo, genera automáticamente los programas de CNC que se adhiere a los principios del mecanizado de alta velocidad, lo que permite un tiempo de mecanizado mucho más corto, vida de herramienta más larga y reducción significativa en el desgaste de la máquina-herramienta en comparación con los métodos convencionales de fresado y con los sistemas de CAM existentes.

Juan José Jiménez resumió los principales objetivos de iMachining en cuatro puntos: “experiencia simplificada”, con un manejo muy sencillo por parte de usuario; generación de trayectorias optimizadas; corte eficiente de la pieza; y altas tasas de arranque de material.

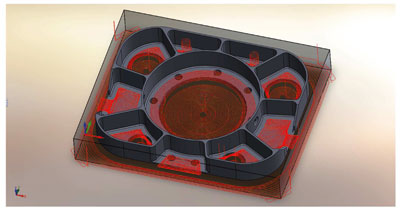

Un beneficio adicional muy importante del uso de iMachining es la gran reducción de las tensiones mecánicas y térmicas sufridas por la pieza en comparación con el fresado convencional. Esto se logra gracias a la única característica de iMachining que garantiza las condiciones de corte exactas para cada punto de la trayectoria de la herramienta, y gracias al éxito de iMachining de lograr el porcentaje más alto en la industria de zonas de corte con trayectorias en espiral. Estos beneficios son de gran importancia para un gran número de industrias, incluyendo la aeroespacial y la del molde.

Este CAM incluye dos opciones: por un lado, generador de trayectorias independientes, y por otro un generador de condiciones de corte, “y es aquí donde iMachining se diferencia de los otros CAM del mercado, que se olvidan de este factor, puesto que es el usuario el que debe dar las condiciones de corte, profundidad de pasada, velocidad, etc.”, afirmó Jiménez.

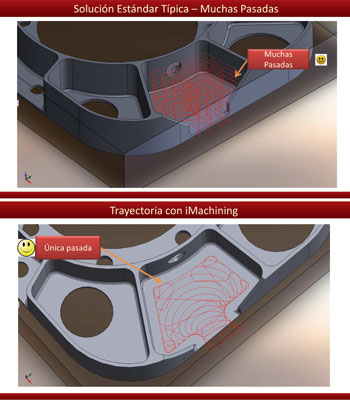

En cuanto a las trayectorias, se planteaban tres dificultades en los sistemas más convencionales: la sobrecarga en las herramientas, con cargas impredecibles; cortes en vacío ineficientes; y trayectorias no tangentes, con cambios agudos en las mismas. En cambio, iMachining proporciona soluciones a todos estos problemas: el solapamiento entre las pasadas está controlado, por lo que no se sobrecarga la herramienta; proporciona el mecanizado exacto del tocho, por lo que no corta en vacío; y ofrece trayectorias tangentes suaves con un mecanizado también suave.

Hay dos factores que diferencian las trayectorias de iMachining con las de otros programas CAM: el uso por un lado de ‘espirales Morphing’; y por el otro de ‘separación inteligente’.

Las espirales Morphing son más eficientes porque provocan menos retracciones, la herramienta permanece en contacto con el material y la máquina avanza más rápido pero con movimientos suaves. En cambio, las trayectorias de solapamiento paralelos incrementan las reposiciones, los golpes de herramienta y de máquina, las entradas y salidas y las retracciones. A diferencia de espirales convencionales se adaptan de forma continua a la geometría del elemento que está mecanizando, maximizando el tiempo de ‘herramienta cortando’.

Por su parte, la separación inteligente de áreas, “que genera zonas para poderlas mecanizar posteriormente” formando espirales Morphing en cualquier geometría y mecanizando las zonas con mayor material primero para así ahorrar tiempo de programación.

Todas las trayectorias de iMachining cortan material, y nunca ‘cortan aire’. Desde la aproximación inicial hasta el último corte, hay una representación del bloque restante que se actualiza continuamente y asegura que cada trayectoria corta realmente material. El sistema aplica un ‘Reposicionamiento inteligente’, a profundidad de corte, para mover la herramienta de un corte al siguiente, y solamente se levanta cuando es absolutamente necesario.

El programa también proporciona control de las condiciones de corte en cada uno de los puntos su trayectoria, cosa que aporta más datos en mecanizaciones de materiales más duros, por ejemplo.

Asistente de cálculo de las condiciones de corte

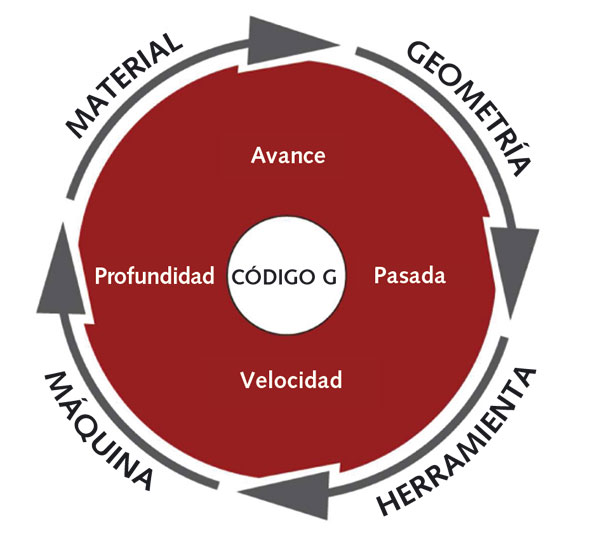

“Hasta ahora ningún software CAM calculaba y proporcionaba los datos de corte, era el operario quien debía dar los valores adecuados”, aseguró Jiménez. Hay que tener en cuenta todos los parámetros, que están relacionados entre sí: avance, velocidad giro, profundidad, etc. El operario debe calcular en función de material a cortar, herramienta… “Trabajar de esta forma tiene sus inconvenientes, porque no se tienen en cuenta todos las variables ni valores ni están sincronizados todos los parámetros, por lo que los resultados no son los más óptimos ni los que permiten mecanizar de forma más rápida”.

Con el ‘Asistente Tecnológico’ exclusivo de SolidCAM iMachining calcula automáticamente las condiciones de corte, teniendo en cuenta todos los parámetros de mecanizado en base a la herramienta, la geometría, la máquina y los materiales. En su base de datos de material todos estos factores están sincronizados, “por lo que el usuario no tiene que definir nada”.

Este asistente es “el primero en la industria”, y calcula avances, velocidades, profundidades y anchura de corte optimizados. Incorpora tecnologías como la llamada ‘Distancia de pasada controlada’ (pendiente de pantente) que asegura que las condiciones de corte de las trayectorias calculadas con iMachining son totalmente correctas, proporciona una carga de herramienta constante y a la vez reduce el desgaste de la herramienta. Asimismo, el control deslizante ‘iMachining Level Slider’ permite que el usuario escoja entre 8 niveles de ajuste para adaptarse automáticamente al agarre ‘real’, el portaherramientas, y las condiciones de máquina.