Interview to Jorge Novella Llorca, manager of Mundimold

Mundimold Is a skilled company in the mould manufacturing for the injection of thermoplastic that initiated his activity like company of support to a plant inyectadora specialised in menaje and plastic boxes. In 1986 it constituted like independent social reason designated Mundimold S.A. and, in 2010, inaugurated some new installations in the population of Ribarroja of the Turia (Valencia) that have more than 3.000 square metres to allow the expansion of the company and cover the growth of the world-wide demand of his products and services, including the extension of the departments of production of high performance as well as the department of R&D.

The main centre of production of Mundimold finds in Valencia but from 2009 has permanent headquarters in Miami (EE UU) and, later expanded his department of R&D in Milan (Italy). Of the same way, has permanent strategic collaborators in Colombia and Italy. “But in addition to the commitment with the customer, Mundimold has from does years a commitment with the quality, labour hygiene and innovation that has seen rewarded with the obtaining of the Certification of Quality ISO 9001, the one of Environingingment ISO 14001 by ENAC and the recognition of the project of R&D for the design and development of moulds of high performance by part of the Centre for Industrial Technology Development pertaining to the Ministry of Science and Innovation”, explains Jorge Novella Llorca, manager of Mundimold.

Which types of moulds do and which capacity of production have in the company?

Mundimold Offers global solutions for the industry of packaging to world-wide level. Our services include the gestión and complete implantation of projects, the investigation and the development of new plastic articles and the manufacture of the metallic moulds for his injection.

The moulds that produces Mundimold, and that find in the rank of weights between 3 and 80 tonnes, are designed for the optimisation of the cycle of production and has allowed us be world-wide leaders inside this specialisation in the sector of the packaging.

Which applications have his moulds, for which products are designed?

National and international customers like Coca-Tail, Pepsi-tail, Fontvella, Schoeller Ark System, etc. have deposited his confidence in Mundimold for the development of his new projects inside the sector of the packaging.

Mundimold Is specialised in the rigid packaging, agricultural boxes, boxes of bottles, industrial boxes, palés, big containers and menaje of high range. The investigation and the internal development and the application of new technologies has allowed us cover all the needs of our customers in the development colaborativo of his needs.

Besides, the company has carried the investigation and the development to all the processes of the company, by means of the utilisation of methodologies Read Product Development and Read Management, allowing us analyse the flows of materials and of information of all the process, visualising the opportunities of improvement.

Mundimold Has established the aim to standardise the clear-cut actions by the multidisciplinary team of improvement, ensure the reliability of the product and of the terms of delivery and, besides reduce the costs and increase the productivity in the ‘Design to Manufacture'.

To reach ours put, that is to create a culture of continuous improvement and gestión of the knowledge that keep in the time, put in practice of form continued activities of work in team (Workshops) with the tools Read Management.

And in his opinion, which will be the tendency in the next years in the sector of the packaging?

Mundimold Guides his steps following a strategic planning that includes studies of international market as well as the gestión of the knowledge of the current and future needs relative to the geographic field as to the field of evolution of the products. This planning allows to identify the potential customers as well as anticipate to his needs. Thus, Mundimold initiated does already 15 years the insertion in markets so shoot like Latin America, EE UU, consolidating this position in the last years in determinate areas like Chile, Peru and Mexico.

With regard to the future tendencies of product, Mundimold bets by the introduction of new plastic materials, ‘compounds' in the articles and the combination of productive processes up to now independent, that allow to our customers reduce the costs of manufacture without reducing neither the quality neither the final use of the same.

Mundimold Has customers in crowd of countries. There are differences regarding the demand of moulds according to the countries? Which?

The demand of projects is related directly with the situation sociopolítica and economic of the country, his demographic growth as well as the increase of the per capita income that influences directly in the tendencies of consumption of his population. On the other hand, with regard to our developments for the agricultural sector, finds influenciada by the new location of the agricultural productive areas, does years Spain and Italy were zones prioritarias and, at present, everything is displacing to countries or emergent areas. For example, the growth of the agricultural sector in Peru is upper to 20% annual.

In which machines and tools trust to fulfil with the exigencias of his customers?

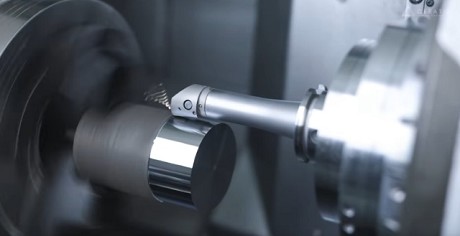

Mundimold, after the investigation of processes and the continuous improvement in the manufacture, beside the specialisation has implanted a planning of acquisition of resources and active with, among others, the strategic aim to reduce the term of delivery of the projects. For this, Mundimold has, among others, of 5 machining centres Mikron of high speed, 3 of them of three axles, 2 machining centres of high performance robotizado of 5 axles with cambiadores of palés, as well as a centre Mecof of 3+2 axles that allows to mechanise plates until 4.000 x 2.500 x 1.500 millimetres multipuesto.

Regarding tools almost 90% of which use are Hitachi.

Precisely with regard to these tools Hitachi, of which have and for which works?

Have of a skilled range of tools of interchangeable plate of desbaste and finishing (ASR Beak, Beak Maxi, ASM Mini, ASPV, ARPF, etc.). By the peculiarity of our moulds find us with the need to mechanise slots for nerves of all type of depth, (having displaced the spark-erosion to a residual employment)- Also have a high range of milling cutters miniature of hard metal with more than 3.000 references in stock of immediate delivery, flat, tóricas and spherical with a very wide range of voladizos with diameters that go from 0,2 until 3 millimetres of diameter.

Which advantages contribute them these tools? What did them decant by them?

Ours philosophy is that the machines work 24 hours 7 days to the week, therefore we need tools that give us reliability in our processes, the maximum performance to level of conditions of cutting and, besides that they guarantee us a time of prolonged work without suffering breaks neither wears. These conditionings fulfil them of form very remarkable the tools of Hitachi.

What value of the company like providers?

The rapidity in the delivery of the tools in less than 24h, his specialisation like manufacturers or the support of his structure of technicians, that contributes a value added like advisers of mechanised. Besides, thanks to the wide network of Hitachi Tool all over the world, the company can give personalised assistance and adapted to the particular needs in an increasingly competitive market. And with the Production 50 and a narrow bilateral collaboration, increase the profitability by means of the analysis and optimisation of the productive processes.

The manufacturers of tools work in new solutions to cover the needs with which can find his customers, already was regarding materials, hardnesses, etc. Is sufficient? The relation customer-manufacturer of tools promotes this work of innovation?

The continuous evolution in new materials and in new processes of manufacture involves a need of relation colaborativa with our providers, in the case of Hitachi, the relation bases in the investigation and the conjoint development, devoting by both parts weekly resources to the continuous improvement. Neither Mundimold neither Hitachi see another way to grow in the gestión of the knowledge.

On the other hand, also the gestión of the tools is a service that offer the manufacturers. It is important for you?

In our case, and because of the specialisation and to the implantation of systems just in time that providers like Hitachi manage of an efficient way, this service does not mean a competitive improvement for Mundimold. But we believe really that the gestión of any appearance or active of the company and the control of the same is a need to cover in any type of organisation.

To finalise, can explain us some current project in which they are working, where the tools can contribute a differential factor?

At present are developing a new concept of palé for the Latin American market. We have checked, after a complex project in collaboration with Hitachi, a significant reduction of our costs in the process of manufacture of the nerves, the slots that configure the base of the palé. This improvement, that has supposed the complete elimination of the process of spark-erosion by penetration and that has allowed us fulfil with some standards of superficial finishing and of reduction of adjust in the assembling, has translated in a reduction of 35% in the term of delivery of the mould and a reduction of costs of 20%.

The flexibility in the politics of assistance to the customer of Hitachi has allowed us obtain these results already in the first real project.