Modernisation of controls and electrical manoeuvres

29 November 2011

However, the technologies of control evolve to a vertiginous rhythm, so that a lot of machines at present in production have remained obsolete precisely in his automation. Besides, the lines modernizan in his mechanical components, well because they substitute elements that have dilapidated because of the wear of the teams, or by the introduction of new additional systems (feeders, transfer, carrier of formats, etc.) in plough to improve the efficiency. But, in a lot of installations, the possibilities of mechanical improvements find increasingly limited in the incorporation of these new elements, because the lines are controlled by old teams of automatisms and his association with third systems of new generation does costly and presents, case to attain , lacks in the provision. And that say has when it requires adapt the installations to the new rules of security. The attain it with old teams of control can result a nightmare. Given the rapidity with that the electronic teams evolve appears, also, a problem with the spares of the automatisms. The spares in his majority discontinued are increasingly difficult to locate and his prices increase substantially of year in year. All this supposes unnecessary and unemployed costs long of machine.

The users see, with frustration, as his machines find in good condition but can not be modernizadas by the limitations of ancient controls. In summary, the modernisation of the control can suppose a decisive factor to improve the installation.

From does some years the team of Fast of Fagor Arrasate is realising works of adecuación of electrical installations and of control to the new technologies, expanding his provision and substituting the obsolete systems by new platforms with important improvements for the installations, so much of production as of equipment. We offer a wide experience in projects of migration of the installations, so much in the control as in the association to teams of last generation.

Each day are more the customers that approach to Fagor Arrasate to pose his interests in this field. After studying them, the company is able to recommend the optimum updates that allow them open doors to future functionalities of the sector, as well as the immediate availability of the teams in the market. Like this, some of the improvements that have obtained after modernizar the control are:

- Increase of speed of signals of control.

- Increase of productions.

- Increase in the number of coin that they can be used.

- Speed in the location and replacement of teams.

- Improves of diagnostics of the teams.

- Minimisation in the stops of the production.

- Chequeo External of all the teams from maintenance.

- Guarantee in the spares.

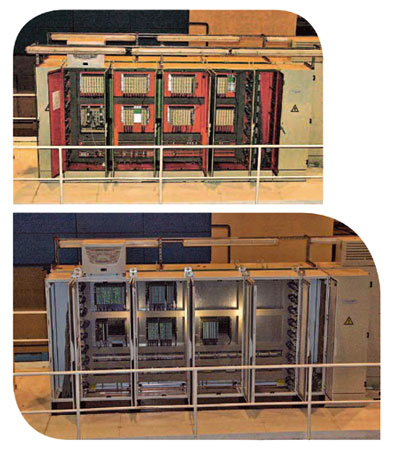

Can see , to continuation, some examples of works already realised:

Migration of the control of press in an installation of Portugal

realised the replacement of the ancient cupboard with a PLC Simatic S5 discontinued by one new with PLC S7 CPU 416 more the necessary extensions.

Modification of a complete installation of a system of stamping

The modernizacion supposed the following works:

- Change of cupboard giving more provision to the installation, with incorporation of a regulator of frequency for the engine with option of change of speed of press.

- New team of control with automaton Pilz for securities and Simatic for management of signals.

- Preparation of screens with diagnostic of the installation.

- Graphic advice of operation to production.

- Visualisation of parameters of press.

- Adjust of encoders by means of screen.

- Historical of failures.

Press monoblock with new control with screen of digital visualisation in the total

The projects of Fagor Arrasate cover different demands:

- Analysis of installations and proposals of improvement.

- Adaptation to rules of security CE.

- Replacement of systems of control and management.

- Migration of projects of any platform.

- Integration of screens of visualisation.

- Diagnostic, prevention and location of failures.

- Integration of new teams to the existent.

- Set up of the installation (modality key in hand).

- Courses of training so much for maintenance as for operarios.

- Continuous advice and coverages in situ or via modem.