La ingeniería en una empresa tradicional sevillana consolida su posicionamiento aeronáutico

7 de septiembre de 2011

Inicios

La empresa surge en 1970 fundada por Antonio González Jaén como pionera en el grabado con fresa. Gracias a su dedicación por la calidad del producto, servicio sin horario al cliente y a la adquisición de la primera máquina controlada por ordenador en 1984, se convirtió rápidamente en el grabador más prestigioso de Sevilla. Merced a esta reputación comenzó a realizar grabados para Construcciones Aeronáuticas y empresas del sector aeronáutico.

Darío González Fernández, hijo del fundador, realizó estudios de Ingeniería Técnica Industrial en la Politécnica de Sevilla y se incorporó en 2001 a la empresa familiar. En 2003 la empresa se trasladó a una nave industrial. A partir de este momento se dejó la dirección en manos de Darío y comenzaron a aplicarse en la empresa los conocimientos avanzados de Ingeniería pero aplicándolos con una filosofía tradicional ya que la figura del fundador todavía tenía mucho peso en la empresa. A la vez que se realizaban cálculos complejos en producción y se aplicaban procesos avanzados de fabricación se mantenía un amor por el resultado, un respeto máximo por el cliente y una economía ajustada (contraria a los altos endeudamientos que se fomentan en las escuelas de negocios). En 2004 se inició el servicio de mecanizado CNC con un notable éxito, trabajando con empresas muy importantes del sector y fabricando piezas muy complejas.

Departamento de Ingeniería

En 2007 creamos una oficina técnica con dos ingenieros técnicos industriales. Su función era investigar y desarrollar productos en los que la empresa tenía dificultades en cuanto a coste y calidad y desarrollar otros productos nuevos para la compañía. Dedicaban un 50% de su tiempo a estos productos, pero además daban soporte en cuanto a cálculos y programación a los trabajos que se realizaban de grabado y mecanizado. También apoyaban en trabajos de calidad y producción cuando era necesario y en proyectos de mejora industrial. Este departamento suponía un aumento importante en el coste de personal de la empresa, pero sabíamos que en algún momento nos daría resultados.

El primer resultado de esta oficina surgió en 2008 cuando se nos pidió oferta para fabricar los mismos accesorios que ya fabricábamos pero en este caso para el nuevo avión A400M. Gracias al departamento creado, ofertamos, además de la fabricación, el diseño y validación de los mismos. Este punto fue determinante para ganar la oferta y finalmente firmar dos contratos.

En paralelo a este proyecto se aplicaban nuevos sistemas de fabricación y gestión:

- Sistema de Gestión de Calidad. La empresa se certificó en las normas ISO 9001 y en la aeronáutica EN 9100 mejorando los procesos de control, evaluación de proveedores, comunicación con el cliente, formación continua, etc.

- Lean Manufacturing. Para mejorar los precios se aplicó la filosofía originada en Japón a través de la cual se mejoran los tiempos de entrega y se reducen los despilfarros.

- Implantación de ERP. Se invirtió en la compra e implantación de un software de gestión integral que reduce nuestras tareas administrativas y nos da información a tiempo real del funcionamiento de las diferentes áreas de la empresa.

- Reuniones de equipo. Se comenzaron a organizar reuniones semanales para organizar la producción, para mejorar aspectos de calidad y para informar de las estrategias de la empresa. Aunque durante este tiempo la empresa no producía sin embargo el personal entendía las necesidades de la empresa, se mejoraba el trabajo en equipo y la respuesta al cliente era coordinada.

- Colaboración con institutos tecnológicos. Comenzamos a realizar colaboraciones con Universidades, centros tecnológicos, laboratorios y asistencia a jornadas técnicas. Notables han sido los resultados con el Instituto Andaluz de Tecnología (IAT) en cuanto al área de diseño, mejora de procesos industriales y aplicación de nuevos materiales.

- Especialización y diferenciación. Al analizar las diferentes líneas de productos, nos dimos cuenta que en algunas teníamos más de 400 empresas competidoras. Esto nos llevó a concentrar nuestros esfuerzos en productos muy avanzados tecnológicamente y en diferenciar otros a través de la calidad y el uso de nuevas tecnologías.

Esquivamos la crisis

En 2008 se comienza a hablar de crisis. Aún tengo en la memoria la cara de Bush anunciando dificultades financieras. Creo que nadie en ese momento pensó como llegaría a afectarnos. Reconozco que yo tampoco. Había escuchado hablar de muchas crisis pero ninguna tenía nada que ver con lo que se avecinaba. Lo otro eran simples bajadas de trabajo que duraban tres meses.

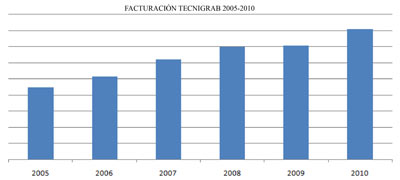

No es hasta el segundo trimestre del 2009 cuando no se nota una parada de los pedidos coincidiendo con un una bajada cíclica del trabajo aeronáutico. Tuvimos que hacer esfuerzos de reestructuración y controlar el gasto pero a final del año se recuperó la producción y todo quedó en un largo susto. A partir de ese momento y fruto de los productos desarrollados y de los contratos firmados la facturación continuó creciendo.

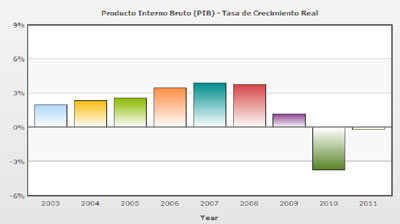

En la siguiente tabla se aprecia el efecto de la crisis en la economía española referida a la tasa de variación del producto interior bruto nacional. En la otra tabla podemos comprobar que esta recesión prácticamente no ha afectado en la facturación de Tecnigrab, es más, podemos comprobar un aumento de la misma en el último año de un 17%.

Trabajo para el futuro

Seguramente no podríamos hacer ahora lo que hicimos en un momento de bonanza económica como fue 2007, ya que tuvimos que aumentar el coste de personal de forma importante.

Si tengo que hacer autocrítica hay dos puntos en los que la empresa podría haber mejorado:

- Diversificación. Deberíamos haber sido capaces de diversificar en otros sectores como el ferroviario o el naval.

- Internacionalización. La siempre difícil y costosa tarea de internacionalización es todavía una tarea pendiente en la cual estamos trabajando. Hay otras empresas aeronáuticas en el resto del mundo que compran los productos que nosotros ofrecemos. Fuera del sector aeronáutico se está produciendo una mejora de la economía en otros países.

No creemos que la crisis pase pronto por eso seguimos trabajando en la mejora de los procesos. Una empresa no debe esperar a que los clientes les pidan productos nuevos o mejoras en los procesos, sino que el trabajo debe ser constante de forma interna y ofrecer las mejoras de forma gratuita. Los proyectos deben hacerse con antelación e intentando prever el futuro. Esta es la tarea del empresario. Si quieres reaccionar cuando tienes el problema encima ya es demasiado tarde, así que tenemos que trabajar hoy, para estar preparados dentro de dos años. Los esfuerzos que debemos hacer hoy con vistas al futuro deben pasar por optimizar la fabricación para adaptarse a la reducción de costes que se está produciendo a nivel global. Boeing y Airbus están trabajando desde hace años en este sentido para competir con empresas de países emergentes (China, Brasil, Rusia, …).

Hemos comenzado dos proyectos de I+D+i que esperamos nos den fruto en los próximos años y hemos creado un plan estratégico para 2011-2016 en el que concentrar nuestros esfuerzos en tres líneas de negocio: placas de identificación, placas de control y placas de protección.