Planificar el mecanizado de moldes y matrices

Cuanto más grande es una pieza y cuanto más complicada es, más importante es la planificación del proceso. Es muy importante adoptar una actitud abierta en lo que se refiere a los métodos de mecanizado y herramientas de corte. En muchos casos puede ser de gran valor tener un colaborador externo que tenga experiencias diversas en múltiples áreas y que pueda proporcionar una perspectiva diferente así como aportar nuevas ideas.

En nuestros tiempos, con la competitividad como premisa para sobrevivir, una de las herramientas fundamentales es la computerización de la producción. En el caso de la industria de los moldes y matrices es una cuestión de invertir en equipos avanzados y en sistemas de CAD/CAM. Pero incluso haciendo esto, es de la máxima importancia utilizar todo el potencial de los softwares CAM.

En muchos casos, la fuerza de la tradición en la programación es muy fuerte. La forma tradicional y más sencilla para programar los recorridos de las herramientas es la utilización de la vieja técnica de fresado copiado, con muchas entradas y salidas en el material. A menudo esto significa que muchos softwares muy versátiles y potentes, máquinas y herramientas de corte se utilizan con muchas limitaciones.

Los sistemas modernos de CAD/CAM se pueden aprovechar mucho más si se dejan de lado formas de pensar anticuadas y hábitos tradicionales.

Si cuando se utiliza una técnica de programación en la que lo principal es cortar material con un valor Z constante, se usan recorridos de herramienta de contorneado en combinación con fresado de rebaje, el resultado será:

- un tiempo de mecanizado bastante más corto

- mejor utilización de máquina y herramienta

- mejor calidad geométrica del molde o matriz mecanizada

- menor pulido manual y tiempo de pruebas

Se ha demostrado que, en combinación con herramientas de amarre y corte modernas, este concepto puede reducir el tiempo de producción a la mitad.

En principio, un trabajo nuevo y más detallado es más complejo y requiere más tiempo. La pregunta que debe hacerse es: ¿dónde es más elevado el coste por hora? ¿en el departamento de planificación de procesos, en una estación de trabajo o en la máquina-herramienta? La respuesta está bastante clara, ya que el coste por hora de una máquina es por lo menos 2 ó 3 veces más que el de una estación de trabajo.

Una vez familiarizados con la nueva forma de programar/pensar, la programación se hará cada vez más rutinaria y más rápida. La experiencia ha demostrado que, a largo plazo, se puede hacer con más rapidez una programación avanzada de los recorridos de la herramienta que con la programación convencional.

Mediante una programación avanzada y el acabado

en una máquina-herramienta de precisión, el tiempo de pulido puede ser reducido

Elección correcta de la herramienta de corte

- definir las exigencias mínimas de radio y la profundidad máxima de la cavidad

- estimar la cantidad de material a eliminar. Es importante tener en cuenta que desbastar y semiacabar un molde o matriz de grandes dimensiones es una tarea que se hace con más eficacia y de forma más productiva con los métodos y herramientas convencionales. Para el acabado siempre es mejor recurrir al mecanizado de alta velocidad. Esto es debido a que el índice de desbaste de material en la alta velocidad es mucho más bajo que en el mecanizado convencional, con la excepción del mecanizado de aluminio o materiales no férreos.

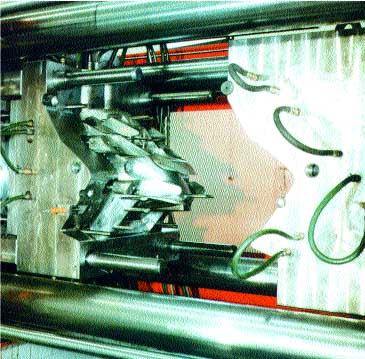

- La preparación (superficies fresadas y paralelas) y fijación de la pieza en bruto es de gran importancia, porque siempre es una fuente de vibraciones. Si se está trabajando con alta velocidad, este punto adquiere todavía más relevancia. Cuando se trabaja con métodos de alta velocidad e incluso con mecanizados convencionales exigentes en lo que se refiere a la precisión del molde o matriz, se debería siempre utilizar máquinas específicas para desbastados, semiacabados, acabados y superacabados.

Las guías y husillos a bolas están sometidos a mayores tensiones cuando se desbasta, por ejemplo. Esto tendrá un mayor impacto en el acabado de la superficie y en la precisión de la geometría de los moldes o matrices que están siendo objeto de mecanizados de acabado en esa máquina-herramienta. Esto resultará en una mayor necesidad de pulido a mano y más tiempo para pruebas. Si recordamos que uno de los objetivos actuales es reducir el pulido manual, se puede concluir que la utilización de la misma máquina para labores de desbastado y acabado es una solución equivocada. Por ejemplo, el tiempo para pulir a mano un molde para un capot de un coche grande puede llegar a las 400 horas.

Si se puede reducir este tiempo con un buen mecanizado, no sólo estamos bajando el coste, sino también mejorando la precisión geométrica del molde. Una máquina-herramienta mecaniza con exactitud aquello para lo que ha sido programada y por ello la precisión geométrica será mejor cuanto más se puedan mecanizar el molde o la matriz. Sin embargo, cuando hay mucho trabajo manual de acabado, la precisión geométrica no será tan buena, por factores como la presión que cada persona ejerce al pulir o el método que utilice, por citar sólo dos causas.

Añadiendo en total unas 50 horas en una programación avanzada (una pieza pequeña) y el acabado en una máquina-herramienta de precisión, el pulido puede ser reducido a 100 ó 150 horas e incluso menos. Existen además otras ventajas si se mecaniza con tolerancias más precisas y acabado superficial. Una de ellas es que la mayor precisión geométrica requiere luego menos tiempos de pruebas. Otra, que por ejemplo un molde para prensas tendrá una vida más larga y que aumenta la competitividad gracias a una mayor calidad de la pieza.

Un ser humano no puede competir en precisión, por mucha experiencia que tenga, con un recorrido de la herramienta computerizado. Si hablamos de aplicaciones de alta velocidad es absolutamente factible eliminar totalmente los trabajos manuales de pulido si se utiliza una programación avanzada y adaptada, máquinas-herramienta específicas y herramientas de corte idóneas.

Los sistemas modernos de CAD/CAM se pueden aprovechar mucho más si se dejan de lado formas

de pensar anticuadas y hábitos tradicionales

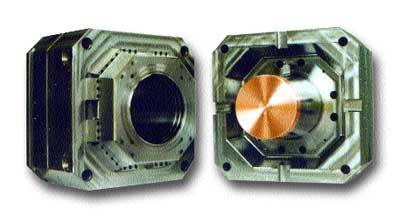

La versatilidad de placas de corte redondas

Por otro lado, si se utilizan las placas redondas, que permiten fresar todos los materiales y en todas las

direcciones, se suavizarán las transiciones entre los pasos y se facilitará el posterior trabajo de semiacabado, resultando finalmente en una mejor calidad del molde o matriz.

Otra característica de las placas redondas es que crean espesores diversos de la viruta, lo cual permite mayores índices de alimentación en comparación con la mayoría de las placas con otras formas. El corte de las placas redondas es muy suave ya que el ángulo de acometida cambia sucesivamente de casi cero a 90 grados. En la máxima profundidad de corte el ángulo de acometida es de 45 grados y cuando se copia con los periféricos, de 90 grados.

Las placas redondas deberían ser siempre la primera opción para desbastar. En el mecanizado de cinco ejes son muy adecuados y prácticamente no tienen limitaciones.