Program in half the time

During the past 40 years, Crabtree has designed and manufactured printing presses, injectors and ovens for drying for clients around the world made from cans of gasoline up boxes of cookies.

Although the origins of Crabtree date back to early 19th century, there is nothing of outdated in this company of 250 employees that today uses the most modern manufacturing practices. His team of designers used the latest CAD systems to update and improve the design and function of the product, while the large number of machines tools CNC workshop allows the company mecanice most of their own components.

All manufacturing and jobs in metal sheets, as well as specialized as the gear cutting tasks are outsourced. This combination of own and subcontracted manufacturing allows that Crabtree produce printing turnkey lines with systems of feeding of metal plates at one end and ovens for drying in the other. The average delivery time to build these systems is 12 weeks.

Timely production

With Code Wizard of EdgeCAM, Crabtree engineers can complete a simple template and quickly generate their own post-processors. "This not only saves us much time, money and problems, but it also gives us more freedom and flexibility to plan production and the reprogramming of the burdens of work", explains Robson.

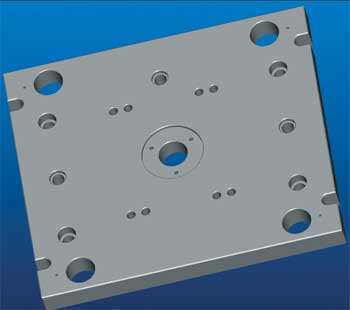

As the installation of four seats of EdgeCAM Crabtree is mainly used for applications of turning and milling of two axes and 2 1/2 axis, developers of the company believe that it is faster return to drawing components within EdgeCAM instead of working with imported data from design SDRCthat are mainly used to work more complex multiejes. Savings produced by the functionality of EdgeCAM, Robson quotes the example of schedule a series of holes machining during the production of large frameworks of press. "The edge of the frame contains a large number of holes." Before it was difficult to see exactly that happened when it was programmed a series of specific diameters. With EdgeCAM, certain holes can connect and disconnect, a characteristic which programmers makes the task much less confusing, which in turn means that there is less chance of errors, and just as we use the mouse to point and click", the programming is also faster".

Currently, 75 percent of the programming carried out by Robson and his team is done off-line, via DNC introduced programs to the appropriate machine. The remaining work is classified as turning "easy", and is programmed in the workshop using the direct input in the control of the machine.

Transitional period

is done off-line, with programmes introduced via DNC to the appropriate machine

Robson also mentions the ToolStore module, which is based on two direct panels side by side. "The edition was a nightmare, but now it only took a few seconds to use a new tool." "In addition, the ability to see a 3D model of this tool in action is something that we didn't have before." EdgeCAM also has a Stock creation command that automatically creates material in relation to the limits of any model of component design. There is also an option of sobre-recorrido, that allows to create additional material beyond the original boundary if necessary.