Impulso a la productividad en el mecanizado de moldes y matrices

El mecanizado de moldes y matrices puede llegar a ser un negocio costoso. Con frecuencia, el material de la pieza es caro, y la programación y el mecanizado suelen ser complejos. No obstante, en un mercado global, poder ofrecer servicios de fabricación de herramientas a precios extremadamente competitivos es esencial para la supervivencia del negocio. Con esto en mente, Sandvik Coromant cuenta con una nueva fresa que ofrece una productividad hasta un 20% superior que las herramientas comparables de la competencia; de hecho, ofrece una solución altamente rentable para acelerar los procesos de mecanizado.

Muchos elementos de la vida diaria se producen en el sector de los moldes y las matrices. Entre estos artículos se encuentran desde bloques de cilindros y cigüeñales, hasta botellas, carcasas de teléfonos móviles y soldados de juguete. Los moldes de estampación, de forja, de inyección y de acabado son sólo un ejemplo de las herramientas de forma compleja que reflejan o copian con precisión la forma de la pieza final que va a producirse en serie.

En la producción de moldes y matrices, la reducción más importante de los ciclos tiene lugar en las operaciones de desbaste y semiacabado, dado que son aquéllas en las que se elimina la mayor cantidad de material. No obstante, los aceros templados utilizados habitualmente para la fabricación de herramientas (>45 HRc) son muy difíciles de mecanizar, ya que suelen fresarse en su estado endurecido para evitar así que el tratamiento térmico afecte a la geometría. Como consecuencia, en los últimos años, los fabricantes de herramientas de corte se han visto obligados a encontrar tecnologías capaces de acelerar esta parte del proceso en materiales como el P20, H13 y S7, entre otros.

Una selección cuidadosa

La estrategia de mecanizado adecuada está directamente relacionada con la elección de las herramientas de corte correctas. Como resultado, la fresa es un factor fundamental para garantizar la productividad y la rentabilidad. La aplicación de un avance elevado y una acción de corte ligera siempre tiene éxito en las fresas utilizadas a estos efectos. Aquí, el secreto reside en una combinación optimizada del diseño del filo y la calidad.

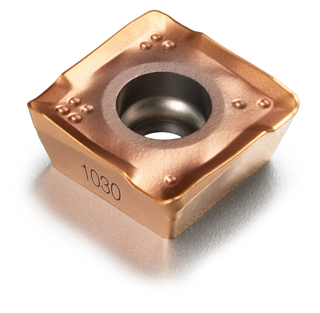

Para ello, Sandvik Coromant ha desarrollado una nueva fresa que ofrece una productividad hasta un 20% superior a las herramientas comparables de la competencia. CoroMill 419 es una fresa de plaquita intercambiable de gran avance con cinco filos por plaquita, dos más que las herramientas de la competencia habituales, que aportan una rentabilidad añadida. Esta fresa está específicamente diseñada para proporcionar un excelente rendimiento en las operaciones de desbaste y semiacabado de aceros templados. Las duraderas plaquitas de la fresa, resistentes y robustas, ofrecen un mecanizado fiable a profundidades hasta 2 mm. Al utilizar plaquitas de faceta paralela, las velocidades de avance recomendadas (fz) para las aplicaciones de planeado son entre 0,5 – 1,1 mm/z. Para las aplicaciones de fresado de perfiles, se recomienda el uso de plaquitas radiales.

La capacidad de la fresa de minimizar las fuerzas axiales deriva directamente de la aplicación de un ángulo de posición de 19° y un ángulo de inclinación axial positivo. Un ángulo de posición reducido genera una viruta más fina, lo cual, a su vez, mantiene un grosor de viruta adecuado para la geometría de la plaquita. Asimismo, un menor ángulo de posición dirige las fuerzas de corte en dirección axial, hacia el husillo, lo cual resulta en una mayor estabilidad y es menos exigente con la máquina. Por este motivo, al realizar operaciones de gran avance, las fresas deben aplicarse con un empañe completo del diámetro, no inferior a la mitad de la anchura de su plaquita. Las fresas con un empañe inferior a la mitad de la anchura de su plaquita se verán sometidas a un efecto de empuje y, dado que el corte no estará equilibrado, esto probablemente provocará más vibraciones.

Rentabilidad añadida

Cada plaquita CoroMill 419 tiene un total de cinco filos de corte: las plaquitas están disponibles en una amplia gama de calidades y cinco geometrías especiales a la medida de los requisitos específicos. La geometría de la herramienta de corte juega un papel fundamental a la hora de controlar el efecto térmico, e influye en cómo se forma y evacua la viruta del corte. Una geometría incorrecta, a menudo, puede dar lugar a un fallo prematuro de la herramienta y crear componentes con un acabado de mala calidad; motivo por el cual las herramientas deben diseñarse específicamente para el mecanizado de materiales templados.

En lo referente a la temperatura, la capacidad de suministro de refrigerante a través de la herramienta de todas las fresas CoroMill 419 permite aplicar refrigerante de aire comprimido para una evacuación de viruta optimizada en el fresado de cavidades profundas y la interpolación helicoidal. Este tipo de refrigeración es preferible porque evita las fisuras térmicas provocadas por la aplicación de refrigerante por inundación en el mecanizado de aceros templados.

Complejidad del proceso

El mecanizado de moldes es una disciplina compleja. A menudo requiere el planeado de áreas tanto grandes como reducidas, el mecanizado de escuadras o paredes profundas y el mecanizado de ranuras largas, profundas y estrechas. Además, el mecanizado de cavidades a menudo requiere operaciones de mecanizado axial y en rampa. CoroMill 419 está indicada para operaciones de planeado y fresado de perfiles, incluyendo el mecanizado en rampa y la interpolación helicoidal, así como el mecanizado de mayor alcance, habitual en muchas aplicaciones de fabricación de herramientas profundas y extrañas.

A lo largo de esta gama de operaciones, se ha demostrado que el planeado de gran avance pone menos exigencias en la tenacidad y más exigencias en la resistencia al calor y al desgaste. Estas últimas pueden superarse, fácilmente, aplicando una calidad más resistente al desgaste y/o al calor. Por ejemplo, para el planeado de acero templado, es recomendable empezar con la calidad GC1010 de Sandvik Coromant y, si fuera necesario aportar más seguridad, con la calidad GC1030.

Altas temperaturas de trabajo

Gracias a su sustrato y recubrimiento multi-capa de PVD de TiAIN (nitruro de titanio aluminio), la calidad GC1030 ofrece a los usuarios una resistencia al desgaste incrementada y una tenacidad del filo optimizada. La calidad resiste bien los recorridos de herramienta poco favorables, los problemas de estabilidad, los largos voladizos y las cavidades profundas. El gran atributo del TiAlN es su habilidad de trabajar a temperaturas hasta 800 ºC. Esta alta resistencia térmica permite al usuario aplicar mayores velocidades y avances sin dañar la herramienta de corte.

Por el contrario, el fresado de perfiles de gran avance en acero templado exige una gran tenacidad de la plaquita. Por ello, al producir escuadras o superficies en 3D, o al mecanizar en rampa o cajear, empezar con una calidad más tenaz puede aportar grandes beneficios. Aquí, es recomendable empezar con GC1030 y optimizar con GC1010.

La calidad de plaquita de PVD GC1010 está indicada para cualquier taller que experimente problemas con las fisuras perpendiculares o la deformación plástica al mecanizar en aceros templados. Un excelente rendimiento está garantizado. Por ejemplo, al mecanizar un componente en acero templado CMC 04.1 (50 HRc), GC1010 duró 24 minutos. La profundidad de corte fue de 2 mm, a una velocidad de 50 m/min y un avance por diente de 0,11 mm.

Ventajas adicionales

Obviamente, en el mecanizado de moldes y matrices, el uso de CoroMill 419 aporta múltiples beneficios más. Por ejemplo, la ligera acción de corte, de gran avance, genera menos ruido, lo que, a su vez, da lugar a un entorno de trabajo más favorable para el operario. El bajo consumo de energía es otra ventaja útil, que pocos pueden ignorar con los altos precios del mercado energético actual. Además, el diseño inherente de la fresa produce menos desechos.

Diseñada para satisfacer las filosofías de mecanizado de las actuales operaciones de fabricación, CoroMill 419 está disponible en diámetros hasta 100 mm para ajustarse a Coromant Capto, acoplamientos de eje o mangos cilíndricos.