Recuperadores de energía

¿Cuántas veces los clientes, y nosotros mismos, nos planteamos por qué utilizar aire comprimido como energía?. Evidentemente la respuesta es que sus múltiples ventajas, todas ellas ampliamente conocidas, hacen que su principal desventaja (energía altamente costosa de producir) pese menos a la hora de tomar las decisiones.

Una vez analizado este punto, ¿significa esto que como usuarios deben asumir que estos sistemas son energéticamente un ‘desastre’?. Evidentemente como especialistas mundiales del sector y como compañía totalmente comprometida con la sostenibilidad la respuesta es no.

Atlas Copco se ha caracterizado durante toda su historia por desarrollar equipos cada vez más eficientes, así como opciones que permiten disminuir el gasto energético asociado a la producción del aire comprimido, por lo que ¿qué más podemos hacer para ayudar a nuestros clientes a hacer del aire comprimido una energía ‘rentable’?

Si analizamos las distintas variables que influyen en los costes de operación de compresor, Coste del Ciclo de Vida, veremos claramente que el consumo eléctrico representa como termino medio, el 70 % del coste de operación total en 5 años de utilización.

Dando un paso más, ¿podemos reducir este consumo eléctrico? La respuesta es sí, principalmente a través de inversión en nuevas tecnologías. Una vez reducido el consumo, bajo la premisa de ‘La energía ni se destruye, solo se transforma’, la siguiente pregunta sería ¿qué ocurre con la energía que se sigue utilizando en el proceso?

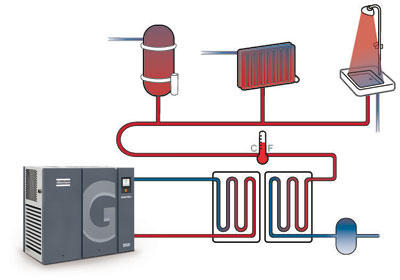

Como valor medio, el 10% de la energía consumida se transforma en calor que permanece en el aire comprimido. El resto da lugar al calor irradiado en el motor, calor absorbido por el líquido refrigerante y calor irradiado en los refrigeradores. Por lo tanto, aproximadamente el 90 % de la energía se encuentra en disposición de ser recuperada y reutilizada para otros fines por ejemplo a través de intercambiadores que permitan calentar agua. Si somos capaces de encontrar la aplicación adecuada en la instalación, podremos generar importantes ahorros energéticos a nuestros clientes.

¿Qué podemos hacer con el calor capturado? Nuestros nuevos kits de servicios de recuperación de energía nos permiten captar este calor para aprovecharlo en otras aplicaciones por ejemplo para:

- calefacción auxiliar o principal

- Calentamiento de procesos industriales y procesos de secado

- Calentamiento de agua para lavanderías, limpieza industrial e instalaciones sanitarias

- Comedores y cocinas grandes

- Industria Alimentaría, química y farmacéutica

- Precalentamiento de agua para otros procesos