Células solares de plástico: la energía de colores

22 de diciembre de 2009

Juan Bisquert

Juan Bisquert (1962, M. Sc. Physics Universitat de València 1985, Ph. D. Physics Universitat de València 1992) es catedrático de Física Aplicada en la Universitat Jaume I de Castelló, donde dirige el Grupo de Dispositivos Fotovoltaicos y Optoelectrónicos compuesto de 12 físicos y químicos. Ha publicado más de 190 trabajos en revistas internacionales y capítulos de libro y ha dirigido más de 20 proyectos de investigación, incluyendo un proyecto Consolider titulado ‘Dispositivos Optoelectrónicos y Fotovoltaicos híbridos para energía Renovable’ (HOPE). Es ‘referee’ en más de 40 revistas científicas, pertenece al consejo editorial de ‘Energy and Environmental Science’, y actúa como evaluador de proyectos en mas de 10 países de Europa, Estados Unidos y Asia.

Los principales temas de actividad actual son la mejora de eficiencia y estabilidad de células de Grätzel, la aplicación de puntos cuánticos como sensibilizadores, la caracterización de células totalmente orgánicas (heterounión masiva) y el estudio de inyección y transporte de carga en LED orgánicos (OLED). En el campo de la tecnología ha creado la empresa spin-off: Xop Física, S.L., que comercializa un sensor de humedad para el riego.

El siglo XX se ha caracterizado por un enorme aumento del consumo de energía por persona, particularmente en los países desarrollados. El paradigma de la extensión de la energía a toda la población fue el vehículo motorizado: coches, camiones, aviones, facilitaron la movilidad de la gente y las mercancías. El motor de explosión aprovecha la notable concentración de energía disponible en los hidrocarburos que dan lugar a la gasolina o el gas-oil (la concentración de energía tanto en volumen como en peso es indispensable, ya que el vehículo debe transportar su propio combustible). Pero ahora somos conscientes que al usar derivados del petróleo, lo que hacemos es consumir de forma irreversible reservas acumuladas por la acción de la fotosíntesis hace millones de años. Con ello, liberamos gases que habían sido fijados en el subsuelo por las plantas primigenias, principalmente CO2. Estos gases interfieren con el tráfico normal de la radiación solar y dan lugar al calentamiento progresivo de la superficie de la tierra, con una probabilidad muy elevada de desembocar en un cambio climático global de consecuencias catastróficas. En términos más inmediatos, el motor es ruidoso y los gases de escape contaminan la atmósfera de las ciudades. Por lo tanto conducir un coche ahora comienza a tener unas contrapartidas visibles para una ciudadanía cada vez más consciente de estos factores.

El presente sistema de energía no es sostenible y se requieren importantes transformaciones que deberán atender a tanto la realidad de las fuerzas del mercado, como la superior realidad de la fuerzas de la naturaleza. Está claro que la actividad científica, tecnológica y económica da lugar a profundos cambios de nuestro entorno, pero no es menos cierto que una vez transformado el entorno, no tenemos más remedio que vivir en él. Los gases de invernadero acumulados en las atmósfera durante las últimas décadas ya están produciendo alteraciones visibles en el clima, y el riesgo de una catástrofe global es tan grave que su solución no se puede diferir a ‘futuras generaciones’, sino que lo tendremos que resolver nosotros, los que estamos aquí ahora. Es el momento de cambiar actitudes y recurrir a la innovación. Seremos más conscientes y responsables respecto al impacto de nuestras actividades sobre el entorno que habitamos, y se producirá una transformación notable del sistema de energía que afectará profundamente nuestro sistema de vida. No sólo exigiremos que los coches actuales recorran cada vez más kilómetros por litro de combustible, mediante el aumento de la eficiencia de los motores. Muy probablemente veremos la extensión de automóviles silenciosos, movidos por baterías alimentadas por energías renovables, que mantendrán limpio el aire que respiramos y producirán cantidades mínimas de CO2. Este cambio será uno de los vectores significativos de la modificación general de las fuentes principales de energía, que dará lugar a una multitud de nuevos productos, necesidades y costumbres.

El sol es la mayor fuente de energía que existe sobre la tierra, y suministra una potencia de unos 120.000 Teravatios (TW) en forma de radiación electromagnética compuesta de luz visible e infrarrojo. Esta potencia es unas 10.000 veces superior al consumo actual de toda la humanidad. La creciente urgencia por encontrar fuentes de energía estables y libres de carbono, ha dado lugar a un extraordinario desarrollo de la energía solar fotovoltaica. La irradiación solar se produce con el mismo ciclo diurno que gobierna todas nuestras actividades, por lo que el suministro de electricidad solar se adapta bien a las necesidades de energía de la población. Está disponible en todas partes y contribuye a la autonomía del suministro energético, y por último, la energía solar se puede producir de forma distribuida, evitando las pérdidas de distribución en grandes líneas de transmisión. En un futuro, seguramente no muy lejano incorporaremos células solares que producirán energía benigna y libre de contaminación, a nuestras viviendas, tanto en el techo como en las fachadas e incluso en las ventanas, a los vehículos, y en la ropa, como en la figura 1.

A pesar de todas las notables ventajas mencionadas, el uso de electricidad solar mediante conversores fotovoltaicos todavía está limitado, y la principal razón es que el coste de los dispositivos que convierten la luz del sol en electricidad, denominados células solares, es bastante elevado, de manera que la electricidad solar, a un coste de unos 4 euros por vatio, no puede competir con otras fuentes de generación (en las que a menudo no se tienen en cuenta los costes asociados a la emisión de gases de efecto invernadero, la inestabilidad política, etc.). Sin embargo, el crecimiento del mercado fotovoltaico mundial es de un 40% en la última década, y de un 100% en el año 2008. La energía solar ha pasado de ser una curiosidad de unos cuantos kilovatios domésticos en los años 1980, a realizar una economía de gran escala que constituye una fuente seria de suministro ya en orden de Gigavatios. Cuando se disipe la polvareda de las batallas legislativas y especulativas ocurridas recientemente en relación con las grandes instalaciones realizadas en España, seguramente podremos comprobar que el coste de las células solares y demás componentes de las instalaciones se reduce progresivamente.

Tecnologías fototovoltaicas de segunda generación

Las células solares tradicionales aprovecharon el conocimiento y la tecnología de los semiconductores empleados en electrónica, y una gran parte del mercado mundial se abastece con células de silicio. Para formar los cristales de silicio se requieren altas temperaturas de preparación, que encarecen el material base. Además, estas células solares, aunque dan altos rendimientos de conversión de luz a electricidad (en torno al 15%) son muy frágiles y poco manejables.

Cuando en los años 80 se reconocieron estas limitaciones a la expansión de la energía solar fotovoltaica, comenzó un notable esfuerzo de investigación y desarrollo para encontrar materiales alternativos convenientes y más baratos, que están dando frutos reales ahora. De estos esfuerzos surgieron varias familias de materiales semiconductores muy prometedores, denominados genéricamente ‘de capa delgada’ (‘thin film’), y que se puede considerar la segunda generación de células solares. Los materiales de capa delgada se llaman así porque son mejores absorbedores de la luz que el silicio cristalino, y funcionan bien con mucho menor grosor de la capa activa (unos pocos micrómetros, frente a los cientos de micrómetros que necesita el silicio cristalino para absorber completamente la radiación solar). Además, no es necesario cortar las capas semiconductoras a partir de un cristal, sino que se pueden depositar sobre un substrato grande, de vidrio, por ejemplo, lo que reduce significativamente los costes de preparación.

Tal como hemos comentado, después de varias décadas de investigación y desarrollo, se ha logrado resolver un sinfín de barreras técnicas para la producción de células solares efectivas de gran área, y en este momento se está produciendo una entrada masiva de las células inorgánicas de capa fina en el mercado. Por ejemplo estamos viendo una gran extensión de la producción de células de silicio amorfo, ya que varias compañías como Applied Materials (EE UU) proporcionan maquinaria llave en mano para producir células muy consistentes y efectivas a gran escala, mediante un proceso continuo que consiste en la deposición de los átomos de silicio a partir de gas silano. Aunque la eficiencia es relativamente baja (alrededor de 7%), el precio del panel por vatio es una fracción del de las células de silicio, y además, este tipo de fábricas, como las ya instaladas en España (T-Solar y Gadir Solar) pueden producir paneles de grandes dimensiones, de unos 5x6 metros cuadrados, que resultan muy atractivos en numerosas aplicaciones. A estos factores hay que añadir la verdadera capacidad de producción de energía de cada tecnología, que no está determinada solamente por el rendimiento de conversión. Efectivamente, la producción de energía por kW instalado depende muy acusadamente del aprovechamiento de la luz de baja intensidad, de la capacidad para captar la radiación lateral, y de la resistencia de la célula para mantener su factor de conversión (la eficiencia) cuando aumente su temperatura. Las células de silicio amorfo se comportan mejor que el silicio cristalino en todos estos aspectos, y por ello, con un rendimiento (a igual área) que es aproximadamente la mitad, el silicio amorfo puede producir más energía al cabo del año y resulta notablemente atractivo. Si añadimos la reducción de costes de manufactura, encontramos un producto muy atractivo incluso para la conversión de energía a gran escala.

Pero el desarrollo más notable dentro de las tecnologías inorgánicas de capa fina es el enorme crecimiento de la producción de células de CdTe (teluro de cadmio). En 2008 la empresa First Solar Inc. EE UU consiguió la rebaja de los costes de producción a 1,1 dólares por vatio, con una capacidad de producción de células por un total de 1 Gigavatio anual. Estos resultados han mejorado en 2009 con la espectacular reducción de costes a 0,85 dólares por vatio en 2009. Con estos avances, las tecnologías de capa delgada, que han logrado una porción del 12% del mercado en 2008, pueden llegar a ocupar un 20% en 2010.

Las células solares de colorante

Mientras se consolidan en el mercado las células inorgánicas de gran área, tecnologías innovadoras de tercera generación basadas en plásticos y nanotecnologías irrumpen con fuerza como elementos prometedores para la conversión fotovoltaica. Mientras las células inorgánicas (tanto las de silicio cristalino, como las de capa fina) se basan en un único semiconductor que realiza la conversión de luz a electricidad, las células solares híbridas y orgánicas adoptan un modelo diferente de conversión fotovoltaica en términos de las propiedades de los materiales, que emplea una mezcla de éstos. Esta estrategia permite reducir las exigencias de pureza y por tanto emplear rutas químicas de preparación de baja temperatura. Se presenta la posibilidad de obtener dispositivos de muy bajo coste cuando se produzcan a gran escala. Además, este planteamiento es muy versátil en cuanto a la variación de materiales y componentes. Por tanto, estas tecnologías presentan grandes ventajas potenciales y características novedosas que facilitarán aplicaciones de integración de las células solares en múltiples ámbitos. Un ejemplo es el complemento de cargador de móvil que mostramos en la figura 1. Además del bajo coste de producción, las células solares híbridas y orgánicas se realizan con facilidad en substrato flexible y ligero, y admiten cualquier variación de color.

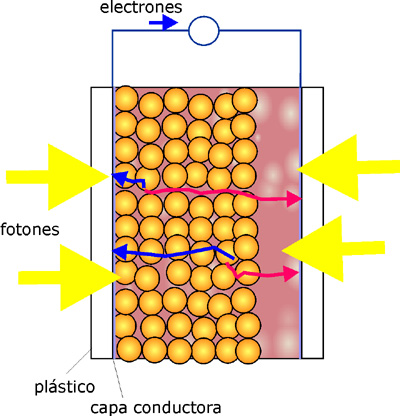

La versión más desarrollada de células híbridas es la célula de titanio nanoestructurado sensibilizado con colorante, descubierta por el científico suizo Michael Grätzel y sus colaboradores en 1991, que para abreviar llamamos DSC (‘dye solar cell’) o también ‘célula de Grätzel’. Estas células toman como base una matriz porosa de un óxido metálico resistente y barato, como TiO2 o ZnO, véase la figura 2. Empleando partículas de óxido de unos 10 nanómetros de tamaño, se consigue un área interna gigantesca para realizar la conversión fotovoltaica. Dicha función corresponde a una molécula orgánica, un colorante que es el absorbedor de luz. Se encuentra anclado en la superficie interna de la matriz y cuando se ilumina inyecta electrones al semiconductor. El circuito interno se completa con un líquido conductor que regenera el colorante oxidado.

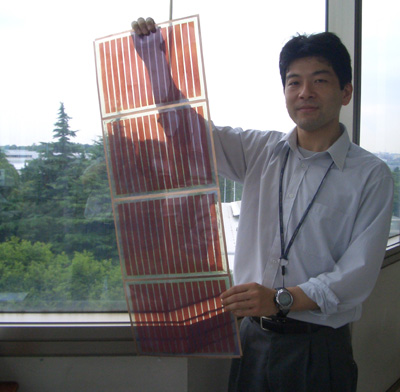

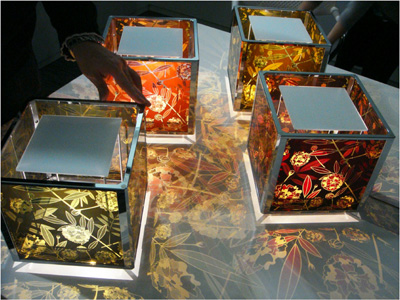

Las ventajas de la célula de Grätzel son numerosas. Los materiales de base son baratos y abundantes, el proceso de preparación es bastante sencillo, y el dispositivo es muy versátil para realizar configuraciones que se adapten a diferentes necesidades. Por ejemplo, la figura 3 muestra prototipos de DSC con la misma estructura pero empleando diferentes colorantes, que permiten realizar el color de la célula de la forma deseada. Hay que resaltar la célula blanca, que utiliza un colorante que absorbe solamente la radiación infrarroja del espectro solar, y por tanto refleja todos los colores. Dicho colorante también permite realizar células solares transparentes a nuestra visión. Por otra parte, como el titanio es compatible con un substrato plástico, también se pueden realizar DSC flexibles, y un ejemplo de paneles de plástico se presenta en la figura 4. Todas estas configuraciones son mecánicamente robustas y se pueden manipular con facilidad.

Es obvio que con esta facilidad de variar los colores, así como los substratos, las DSC pueden adaptarse a un gran número de nuevas aplicaciones. Una característica muy importante de las DSC es su facilidad de integración con elementos arquitectónicos, vehículos, etc. Dyesol, una compañía radicada en Australia que se dedica al suministro de materiales y maquinaria para la producción de DSC, ha promovido varios proyectos en Europa que ya tratan de realizar DSC para integración en arquitectura. El proyecto Chose, en Roma, desarrolla células de colorante traslúcidas en substrato de vidrio para fachadas de edificios, mientras que Chorus, en Cardiff, Gran Bretaña, exploran las DSC sobre substrato de acero que se pueda integrar en techos industriales.

La presencia de elementos orgánicos en las células híbridas, permite incorporar un sinfín de materiales con propiedades deseadas, pero por otra parte estos materiales son menos resistentes a la degradación que los materiales inorgánicos. Durante mucho tiempo existieron dudas, en el ámbito de la investigación, sobre la viabilidad de las células de Grätzel para resistir años de operación en las altas temperaturas que se producen cuando la célula se calienta al sol. Sin embargo, en el momento actual estas reticencias se han superado. Ahora muchos laboratorios, tanto científicos como industriales, están llevando a cabo el proceso de escalar las células a gran tamaño, así como el montaje de líneas piloto. Se producen células en grandes cantidades y se puede comprobar su consistencia y durabilidad. También se ha realizado un notable esfuerzo para obtener líquidos viscosos, geles, sellantes y colorantes que permitan la operación prolongada. Varios laboratorios están realizando tests similares a los de las células de silicio amorfo, para garantizar la calidad de sus productos. Por otra parte, las eficiencias de conversión de las células récord (en área menor que 1 centímetro cuadrado) siguen aumentado. El profesor Peng Wang, del Instituto de Química Aplicada de Chengchun, en China, es un experto en el desarrollo de colorantes avanzados que ha reportado el año 2009 varias veces eficiencias superiores a 11,1% a iluminación equivalente a un sol. Y en el congreso de Materials Research Society, celebrado en Boston en diciembre de 2009, Michael Grätzel reportó la primera célula de colorante que supera la eficiencia de conversión de luz a electricidad de 12%.

Todo hace pensar que la tecnología DSC está despegando el vuelo en este momento para integrarse en el mercado como una opción más, quizás al principio pequeña en comparación con las tecnologías ya establecidas, pero con potencial para convertirse en una opción muy importante para la conversión fotovoltaica. Las DSC tienen una notable capacidad para captar radiación difusa o de baja intensidad, y son células excelentes para productos de interior, como el prototipo de lámpara producido por Sony Corp., figura 5. Tal como hemos explicado, por sus propiedades de transparencia y color a medida se pueden integrar en ventanas, fachadas, techos de vehículos, etc. Y también constituyen una opción destacable para la conversión de energía a gran escala. Es necesario aumentar las eficiencias y la estabilidad, pero este proceso puede producirse de forma rápida, ya que depende en gran medida de las inversiones de capital para desarrollar la tecnología con el incentivo de obtener una buena posición de salida en un futuro gran mercado. Además, el bajo coste de la manufactura y la maquinaria para producir DSC, en comparación con la referencia de las células de silicio amorfo, reduce notablemente las inversiones necesarias para instalar una planta de producción. Las menores demandas de capital pueden dar lugar a una rápida expansión de las tecnologías fotovoltaicas híbridas, ya que la barrera para el arranque es mucho menor. Ciertamente, las inversiones y los proyectos de industrialización son ya una realidad. Por ejemplo 3GSolar es una empresa basada en capital de inversión situada en Tel-Aviv que ha desarrollado la tecnología DSC durante los últimos años. En cooperación con el profesor Arie Zaban de la Universidad de Bar-Ilan, han puesto a punto un sistema innovador para ampliar el area activa de las células mediante protección interna de los contactos. De este modo 3GSolar ha demostrado paneles estables, y su objetivo inmediato es realizar células de 15x15 centímetros con eficiencia del 7,5%, que permitirán una eficiencia de 7% a nivel de panel, para conseguir una producción de 8 Megavatios anuales a un coste de manufactura de 1,40 dólares por vatio.

Las células solares orgánicas

Otra tecnología que experimenta actualmente un desarrollo espectacular son las células basadas en mezclas de componentes orgánicos. La actividad en este ámbito también tuvo comienzo alrededor de 1990, cuando empezaron a utilizarse profusamente los plásticos conductores. En 1991, el profesor Richard Friend y sus colaboradores, demostraron en la Universidad de Cambridge, Reino Unido, el LED (dispositivo electroluminiscente) orgánico, que rápidamente dio lugar a aplicaciones comerciales, y hoy se emplea normalmente en pantallas de teléfono móvil. Los LED orgánicos también empiezan a abordar el mercado de las televisiones de gran tamaño. Sobre la base de estos eficientes polímeros emisores de luz, el premio Nobel de química, el profesor Alan J. Heeger, de la Universidad de California en Santa Barbara, y numerosos colaboradores en Europa, realizaron células solares compuestas de mezclas de un polímero conjugado, absorbedor de la luz, y otro polímero aceptador de electrones, este último normalmente basado en la famosa molécula en forma de balón de fútbol conocida como fulereno.

Las células de plástico tienen una serie de características que las convierten en un dispositivo prometedor con un sinfín de aplicaciones. Por ejemplo, se pueden usar tecnologías de impresión para producir células solares igual que se hacen periódicos. Además, se adaptan de forma natural a dispositivos portátiles de electrónica, y tarjetas de crédito o de identificación. A medida que se desarrolle el campo de la electrónica orgánica, las células orgánicas aparecen como el complemento ideal para proporcionar con autonomía la electricidad que necesitan los nuevos dispositivos.

Sin embargo, existen algunos impedimentos para realizar este tipo de aplicaciones. A diferencia de las DSC, las células orgánicas carecen de una matriz rígida de semiconductor. La morfología interna de la célula, es decir, la mezcla de materiales orgánicos, puede experimentar transformaciones durante la operación a iluminación de un sol. Además, los polímeros conjugados son relativamente reactivos en el ambiente, que degrada las propiedades de la célula. Por estos motivos, y además por las eficiencias muy bajas que se conseguían al principio, durante muchos años estas células no fueron consideradas un candidato convincente para dar lugar a productos industriales. Din embargo, en los últimos tres años, aproximadamente, la situación ha cambiado radicalmente. En 2007 el grupo de Heeger reportó por primera vez eficiencias superiores a 5%, y desde entonces se produce un aumento sostenido, que actualmente llega al 7%. Importantes industrias químicas han lanzado proyectos de desarrollo para obtener las moléculas más efectivas en estas células. Por ello, el desarrollo actual de los materiales se encuentra envuelto en el secretismo característico de competición por obtener la propiedad intelectual de los mejores materiales. Mediante la mejora de materiales fotoactivos, y con robustas barreras de encapsulado, Konarka, una compañía con capital de inversión de capital basada en California, y bajo la dirección técnica de Heeger, ha demostrado pequeños paneles que mantienen los parámetros sin degradación durante un año a la intemperie. También en Europa se llevan a cabo importantes proyectos de demostración donde se ensayan las técnicas ede manufactura para producir células orgánicas en grandes cantidades. La figura 6 muestra paneles del Laboratorio Nacional para Energía Sostenible de Risø, en Dinamarca. En este proyecto, dirigido por el profesor Frederik Krebs, se han realizado panales orgánicos de 1 x 1,7 metros, formado cada uno por 24 módulos de 20 x 25 centímetros. Cada panel produce unos 11 vatios.

Durante la década de 1990-2000, la actividad de investigación en este tipo de células en España fue muy escasa. Fue el profesor Pedro Salvador, investigador del CSIC, quien primero realizó trabajos sobre DSC, en colaboración con investigadores de Berlín. A principios de la década de 2000, el grupo de Juan Bisquert, en la Universitat Jaume I de Castelló, comenzó a obtener resultados destacados que posteriormente han tenido un gran impacto en cuanto a los principios de operación y métodos de caracterización de DSC.

Recientemente, las actividades científicas en estos ámbitos de investigación han experimentado una notable extensión. A medida que la comunidad científica internacional avanzaba en este tipo de estudios, muchos investigadores españoles se interesaron por el tema. En 2007 se obtuvo un impulso importante a la investigación con un proyecto Consolider denominado HOPE (Dispositivos Híbridos y Orgánicos para Energías Renovables), dirigido por Juan Bisquert. El proyecto conlleva una dotación de 4.000.000 de euros para un equipo de unos 100 investigadores durante 5 años. Este proyecto trata de coordinar e impulsar la investigación sobre dispositivos híbridos y orgánicos con un enfoque muy aplicado, en consonancia con el desarrollo actual de dicho campo de investigación. Posteriormente, el gobierno de España ha proporcionado otro impulso a estos temas al subvencionar el proyecto Fotomol, dedicado a actividades preindustriales, y dirigido por Emilio Palomares, investigador ICREA en el Institut d’Investigacions en Química de Catalunya, en Tarragona. Por lo tanto, los grupos de Bisquert y Palomares realizan en la actualidad dispositivos DSC, y el grupo de Hernán Míguez, investigador del CSIC del Instituto de Materiales de Sevilla, investiga el acoplamiento de cristales fotónicos a células de colorante para mejorar sus propiedades ópticas. También hay que resaltar los resultados del profesor Tomás Torres, de la Universidad Autónoma de Madrid, que ha sintetizado un conjunto de colorantes basados en ftalocianinas con una gran capacidad de absorción de fotones en la parte roja en infrarroja del espectro solar. Por otra parte, el doctor Henk Bolink realiza células orgánicas en el Instituto de Ciencia Molecular de Valencia, y Roberto Pacios, investigador del centro de investigación Ikerlan de Mondragón, ha realizado pequeños módulos de células orgánicas para integración con otros instrumentos.Gracias a estas contribuciones, y a la otros grupos que participan en el proyecto Consolider HOPE (http://www.consoliderhope.uji.es/), podemos afirmar que actualmente los investigadores españoles constituyen una fuerza notable en el campo de las células solares híbridas y orgánicas, y son capaces de proponer nuevas ideas y materiales.

Sin embargo, en el campo de la industrialización de las células solares híbridas y orgánicas la situación es menos esperanzadora. Por un lado tenemos que la investigación competitiva comenzó con muchos años de retraso respecto de países del norte de Europa y de Asia. Por otro lado, aunque en este momento la base de personal especializado y conocimiento científico se encuentra disponible en varias Universidades y Centros Tecnológicos, el lanzamiento de proyectos de industrialización requiere inversiones arriesgadas. En este aspecto tenemos la desventaja de la falta de cultura de inversión en innovaciones científicas y tecnológicas. Sin embargo, en el pasado reciente se han producido muchos acontecimientos que demuestran que las inversiones aparentemente ‘seguras’ y rápidamente ‘rentables’ no siempre lo son tanto. Es posible que comience un cambio de mentalidad que haga fluir las inversiones a apuestas de mayor riesgo pero con enormes beneficios potenciales. Tal como hemos explicado en este artículo, en el momento actual, se produce la coalescencia de las innovaciones científicas sobre células solares híbridas y orgánicas realizadas en los últimos años, en productos competitivos que saldrán al mercado en los próximos años. Es por tanto el momento adecuado para participar en la competición por desarrollar los productos más atractivos.

Por último, debemos indicar la necesidad que las políticas de apoyo público, que incentivan las instalaciones fotovoltaicas, tengan un mayor grado de planificación y serenidad para evitar los altibajos que han ocurrido recientemente, y así puedan dar lugar a un desarrollo estable y sostenido de la industria fotovoltaica. Sobre todo, dichos incentivos deben apoyar los elementos innovadores que darán una ventaja en un mercado extraordinariamente competitivo. También es muy importante facilitar que los consumidores puedan incorporar la producción de energía fotovoltaica en sus viviendas con pequeñas instalaciones, eliminando las lentísimas barreras administrativas que existen en la actualidad.

Nota del autor

Estoy muy agradecido a Tsukasa Yoshida, Tsutomu Miyasaka, Reiko Ogura, Torben Damgaard Nielsen y Frederik Krebs, por proporcionar las imágenes que ilustran este artículo. Nuestro trabajo en células solares híbridas y orgánicas está financiado principalmente por los proyectos de MCIN Consolider HOPE CSD2007-00007 y MAT2007-62982, y por el proyecto Prometeo 09I179 de la Generalitat Valenciana.