Latest in the sanitation of piping solutions

April 23, 2010

In fact, the CIPP cured in work with UV system, is beginning to develop in the beginning of the 1980s (it has more than 20 years of experience) and so the glass fibre fabric are used as the basis and the resin polyester ISO-NPG or vinylester, fotopolimerizables.

Both the manufacture of the fabric and its impregnation, are carried out at the premises of the manufacturer through an industrial process that ensures the consistent quality of the final product. Once soaked, the gilding is transferred to work in packages resistant to UV radiation, not being necessary to use refrigeration transport.

Sleeve Liner with glass fibre reinforcement: first quality for multiple applications

Plastics reinforced with fiberglass (FRP) are used for decades in applications where industrial materials are required maximum stability, excellent chemical resistance and extreme durability.

Particularly important are the plastics reinforced with fiberglass in aviation technology and space, as well as in the the automotive industry, manufacturing of pipes etc. Most of the times are used as fiber composites, (a composite is a composite of two or more together materials that has properties different from its components taken separately) sleeve liner of FRP, glass fibres reinforced resin (matrix) in which embuten and permeate.

Range of application

With sleeves FRP liner is possible to rehabilitate all usual cross sections of the pipes. (See 3 typical examples).

Installation: I shot with winch

The implementation work is performed with the gilding in driving to rehabilitate through existing registration wells, by shooting a winch, without need for civil works of any surface, even for large diameters.

In order to ensure the homogenous polymerization of the gilding, the entire process in controlled and registered for the computer.

This procedure is the only one which allows the visual control of the interior of the gilding during the curing process.

After rehabilitation the client receives a comprehensive report that includes a detail with the registered parameter values.

Advantages of the system of the fiber of glass curated by UV

The advantages of this system come largely from the quality of the materials used and the 'cleaning' of light curing process, as well as a major circumferential stiffness due to the use of fiberglass.

No retraction, this system gets the best values of impermeability and resistance to bending, ensuring maximum tightness. It also ensures the highest quality of manufacture due to the industrial process of manufacture and impregnation of the manga.

It stands out also for ease of transport and storage, great stability at room temperature, the possibility of storage for several months and the rapidity of execution, with a speed of setting up to 2 meters per second.

Technology at the highest level: the innovation as a principle

- The CIPP system is used with success since the 1970s

- It is applicable to almost any driving

- Leader in sanitation

- It prolongs the useful life of the pipe 50 years

- Up to 400 m

- Permanent evolution, adapted solutions

- Design governed by international law

Thanks to the flexibility of the material used with CIPP installation lengths can be made up to 400 millimetres, without problem, in a single operation, the pipe to rehabilitate must be clean of sediments and obstacles that from entering it, according to the State of the pipe, and according to the static requirements, the gilding wall thickness varies between 3 and 30 mm. Relying on the international classification for coating systems, we can offer our customers according to need different CIPP procedures which differ both in the structure of the (amount and type of layers), lining of the type of used resin, of the thickness of wall or of the technology of hardening.

The CIPP procedure is being used since the 1970s successfully for the sanitation of drinking water and sewage pipes, based on the constant improvement of materials and equipment used, this procedure has meanwhile credited as leading technology for sanitation. This procedure can rehabilitate the way more fast, economic, ecological and effective all sorts of sections (circular, oval, special, etc.). The high quality of this technology guarantees a minimum time of use of 50 years. This technology for the rehabilitation of pipelines is based on a flexible tube impregnated resin is introduced in the pipe to rehabilitate a pit of registration to another with subsequent hardening or hardening process.

Data from pipes to rehabilitate types of pipes

Where and what kind of pipes can we rehabilitate?

Today day is a program with the most different procedures for the inspection, cleaning and renovation of all kinds of pipes, such as:

- Waste water

- Drinking water

- Gas

- Petroleum, petrochemical

- Industry

For each problem of leaks in open conditions or pressure, we offer a quick, simple and economic solution.

Operation and maintenance

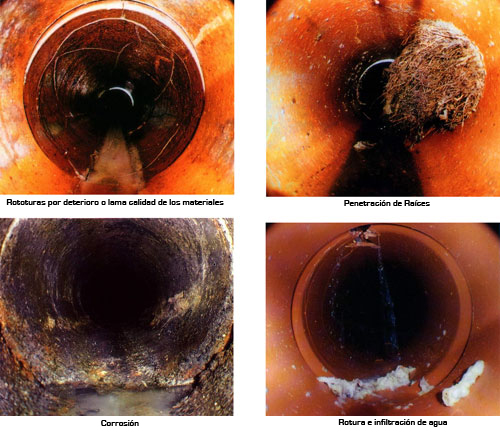

In the operation and maintenance of pipes, the main challenges are given by the antiquity of the existing management systems; flow losses high, leading to contamination of the subsoil; corrosion and penetration of roots; or the difficulty in the urban core of the cities for the excavation. Also involved the breakage of pipes due to the natural decay and poor quality of the materials; and the infiltration of groundwater to the network with the increased flow thereby creating an important energy expenditure of the sewage treatment plants.

Everywhere, pipes suffer a deterioration due to sediment, erosion wear and tear, aging and corrosion, conditions of the ground, etc., generating a danger to the environment with the loss of valuable raw materials such as drinking water, gas, oil, etc. as shown pictures and as we have seen previously in other images are back to show the impact that with more frequency we are in the network.

Advantages of the systems of curing in situ CIPP

What can we offer them?

The conventional replacement of pipes through excavation is expensive, slow, noisy and generally raises considerable problems for the movement and pedestrian traffic. With the implementation of the technology of collectors without opening of ditch rehabilitation we are avoiding cutting path and provision guaranteeing us a minimal environmental impact and a performance that you can spend all the quality controls completed once the work.

The advantages of the sanitation of pipes without open ditch found on the following aspects:

- High profitability

- Protection of existing infrastructures and urban roads

- Extremely reduced construction times in comparison with conventional methods.

- Minimizing or avoiding the court via and supply

- Minimal environmental impact, with a significant reduction in noise

- Success and lasting guarantee.

As a systems of rehabilitation are the gilding of fiberglass cured by ultraviolet; the Manga Polimerizada system; and the setting with teams of ultraviolet rays.

The gilding consists basically of a fabric of polyester reinforced with fiberglass FRP, seamless of any kind, steeped in unsaturated polyester resins.

The fabric used Duroplastic polyester and fiber glass in proportions suitable to enable an optimal light curing of the resin and at the same time, obtain optimal mechanical properties and durability.

It requires little time for the process of setting, so it minimizes the environmental impact in terms of energy consumption and emissions of estirenos, this system offers the highest levels of strength.

As regards the range of application, we can say that it is mainly designed for sanitation systems or pipes of industrial pipe from 150 and up to 1,200 mm in section. The sewers rehabilitated with sleeves fulfilled its function reliably with minimal wall thicknesses and can pay off with a minimum of 50 years, as investment in the long term in the municipal infrastructure

Finally, on the sleeves of FRP, highlight that they are light, robust and with excellent mechanical properties. Thanks to a complex of specially developed glass fibres obtained a remarkably uniform dilatation in all around. And given the excellent mechanical properties of the gilding glass fibre, it is possible to achieve a fully self-supporting rehabilitation with a reduced thickness, which allows an outstanding improvement of the hydraulic properties of the new leadership, estimated at 40% the improvement of the hydraulic capacity of the new network after its rehabilitation.

Previous works

The preparatory work for a sanitation of pipes are often generally consist in the cleaning of the sections to rehabilitate and determination of the State through inspection by CCTV. Piping systems are constantly exposed to influences of the environment, which as we have explained above can give rise to

- Corrosion

- Dirt

- Inlays on the surface of the tubes

- Penetration of roots

- Cracks and vanishing points