Un tejido cerámico para industrializar la construcción

18 de mayo de 2011

El trabajo con cerámica en construcción está normalmente supeditado a la pericia del obrero que coloca tradicionalmente el material pieza a pieza sobre la superficie. Justo la idea contraria a lo que introduce Flexbrick al facilitar unas rutinas de trabajo mucho más industrializadas que ofrecen numerosas ventajas para la construcción con cerámica e innovadoras opciones para los arquitectos.

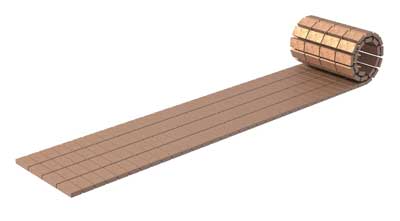

¿Pero cómo funciona este sistema patentado? Todo se fundamenta en el concepto de tejido cerámico ideado por Sarrablo, que contó con el apoyo de 2,5 millones de euros invertidos por Malpesa y Piera Ecocerámica. “Se trata de piezas cerámicas con el formato de siempre armadas sobre un trenzado de acero inoxidable que permite acometer formatos de grandes dimensiones y con una gran perfección geométrica”, señaló durante la presentación celebrada en la sede del iTec de Barcelona. Además, cada pieza de cerámica tiene dos ranuras por las que entra la malla, sin soldaduras, lo que refuerza la vida útil del producto.

La malla de acero, provista por la compañía Estruct, no sólo refuerza la estructura sino que es lo que realmente hace posible el principio de flexibilidad de la marca Flexbrick y la transición hacia un modelo de producción industrial. Como las piezas van prendidas del acero se pueden idear formatos de hasta 20 metros lineales, que se transportan. o plegados en palets, o enrollados en bobinas como si de una alfombra se tratase. Asimismo, el conjunto permitiría el enganche a través de grúas para su traslado en la obra.

“El tejido flexible se adapta a cualquier curvatura con ejecuciones próximas a las de obra civil”, asegura Sarrablo. “En ocasiones, se puede ejecutar hasta diez veces más rápido en comparación con el sistema tradicional pieza a pieza”. La precisión y calidad en la colocación de las piezas viene garantizada por el lugar donde se origina el tejido: un taller de la misma obra al aire libre. Allí, las máquinas tejedoras (prototipos todavía) se encarga de hilar la malla de acero para que el operario se encargue de posicionar cada pieza sin perder detalle, valiéndose de unas juntas bien alineadas, y bajo unas mayores medidas de seguridad. En el taller también se confeccionan las distintas variaciones en la trama de la estructura, lo que da lugar a un amplio configuración de diseños (en rompejunta, en retícula y calado, entre otros) y gamas cromáticas.

Y de ahí a la obra en cuestión. Dice que el director general de Piera Ecocerámica, Lluís Pinardel, que la construcción con Flexbrick se inspira en lo que sería “la fabricación de un automóvil en una planta de ensamblaje y que resulta un “elemento innovador que se alinea con las necesidades de arquitectos y constructores”. En este sentido, el presidente de Cerámica Malpesa, José Malpesa, se refirió al producto como “un traje a medida para proyectos constructivos específicos”, a la vez que alabó el ahorro que reporta su utilización en obra, entre un 20 y 25% más económica en el caso de las fachadas.

Aplicaciones

Entre las variadas aplicaciones del sistema destacan los revestimientos horizontales como pavimentos de zonas urbanas y jardines, pavimentos interiores y cubiertas planas. Asimismo, Flexbrick está diseñado para ejecutar pavimentos drenantes por medio de las juntas y posibilitar el crecimiento de vegetación o el uso de gravillas sin que se produzca un movimiento de las piezas de cerámica bien sujetas por la malla de acero, que aumenta su resistencia.

El ritmo colocación del producto en estas superficies puede alcanzar los 250 metros cuadrados al día, requiriendo solamente dos operarios y una grúa, según explica Sarrablo, que compara este procedimiento con el que se lleva a cabo para acondicionar los campos de fútbol.

Los revestimientos colgantes como fachadas ventiladas, celosías o cubiertas inclinadas o curvas son otro de los grandes beneficiados por el tejido cerámico. Los anclajes de acero en los laterales impiden el desplome, por un lado, y la versatilidad del producto lo hace adaptable a cualquier curvatura, por otro.

La ligereza y resistencia permite al arquitecto proyectar techos catenarios en seco y envolventes continuas para construir pérgolas, bóvedas falsos techos de acabado cerámico con un menor impacto en los costes. Así, por ejemplo, en el montaje de una bóveda, se utilizan encofrados ligeros que aceleran la puesta en obra.

En cuanto a los paneles mixtos, el sistema admite combinación con cualquier elemento constructivo de hormigón armado. El tejido se inserta en el molde de prefabricación y evita que las piezas cerámicas se muevan mientras se vierte el hormigón, quedando totalmente incrustadas en él.

Debido a esta adaptabilidad a materiales como a estructuras arquitectónicas, las aplicaciones de Flexbrick se extienden también a ámbitos como el de la obra pública, mobiliarios urbanos, encofrados colaborantes, estabilización de taludes, gaviones, arquitectura efímera y murales decorativos.

Confianza en el producto

Tanto Malpesa como Piera Ecocerámica participan al 50% en la empresa encargada de comercializar Flexbrick, Flexbrick Tejidos Cerámicos, que contó con su propio stand en la pasada edición del salón Construmat. El objetivo de la compañía es su sistema en el mercado a finales de este año antes de comenzar el proceso de expoertación internacional. De hecho, Sarrablo nombró a Colombia y Brasil como uno de los mercados que había efectuado demandas concretas de tejido.

De momento, la empresa trabaja en crear la infraestructura para fabricar en serie, pero confían en las posibilidades del producto, tal y como recalcó Malpesa: “Hace 5 años que empezamos oír a Vicente Sarrablo hablar de esta idea y, desde entonces, nos entusiasmamos con ella porque pensamos que podía ser una innovación importante en el ámbito de los sistemas de construcción”.

Durante los cuatro años en que se ha ido desarrollando la investigación sobre Flexbrick, uno de los proyectos más reseñables es la construcción de una vivienda unifamiliar en Sant Martí de Tous (Barcelona), considerada por Vicente Sarrablo como un prototipo para algunas de las aplicaciones del sistema.

El resultado final es un ejemplo de arquitectura textil a partir de las soluciones de Flexbrick, con un catálogo de aplicaciones que van desde la bóveda cerámica hasta la cubierta curva pasando por los paneles mixtos y varios pavimentos.