Tratamiento mecánico biológico de residuos urbanos

17 de febrero de 2010

La instalación mecánico-biológica preparará el residuo en función de el tipo de residuo a tratar, su composición y cantidades, la legislación aplicable y los requisitos del cliente, además de las características del tratamiento finalista. Con todo esto, la instalación deberá adaptarse al cumplimiento de la jerarquía de gestión de residuos urbanos primando las opciones de selección de materiales para el reciclado y otro tipo de valorizaciones. Esto se consigue mediante:

- La máxima recuperación de fracciones orgánicas (compostaje o estabilización y otros procesos biológicos).

- La máxima recuperación de metales y de compuestos metálicos (selección de férricos y aluminio).

- La máxima recuperación de otras materias inorgánicas (selección de vidrio, plásticos, briks, etc.) tanto de las reciclables como de las destinadas a la preparación de combustible valorizable térmicamente.

Marco legislativo

Según la Directiva 2008/98/CE, artículo 3, la valorización es cualquier operación cuyo resultado principal sea que el residuo tenga una finalidad útil al sustituir a otros materiales que de otro modo se habrían utilizado para cumplir una función particular. Por otra parte, según esta directiva, la eliminación es cualquier operación que no sea la valorización, incluso cuando la operación tenga como consecuencia secundaria el aprovechamiento de sustancias o energía.

Las siguientes operaciones de valorización de los residuos según la Directiva 2008/98/CE, anexo II son:

- R1 utilización principal como combustible u otro modo de producir energía.

- R2 recuperación o regeneración de disolventes.

- R3 reciclado o recuperación de sustancias orgánicas que no se utilizan como disolventes (incluidos el compostaje y otros procesos de transformación biológica).

- R4 reciclado o recuperación de metales y de compuestos metálicos.

- R5 reciclado o recuperación de otras materias inorgánicas.

- R6 regeneración de ácidos o de bases.

- R7 valorización de componentes utilizados para reducir la contaminación.

- R8 valorización de componentes procedentes de catalizadores.

- R9 regeneración u otro nuevo empleo de aceites.

- R10 tratamiento de los suelos que produzca un beneficio a la agricul tura o una mejora ecológica de los mismos.

- R11 utilización de residuos obtenidos a partir de cualquiera de las operacione s numeradas de R1 a R10.

- R12 intercambio de residuos para someterlos a cualquiera de las operaciones enumeradas entre R1 y R11.

- R13 almacenamiento de residuos en espera de cualquiera de las operac iones numeradas de R1 a R12.

La Directiva 2008/98/CE, artículo 4, establece la jerarquía de residuos que sirve de orden de prioridades en la legislación y la política sobre la prevención y la gestión de los residuos:

1.- Prevención

2.- Preparación para la reutilización.

3.- Reciclado.

4.- Otro tipo de valorización, por ejemplo, la valorización energética.

5.- Eliminación.

En el R1 (utilización principal como combustible u otro modo de producir energía), se incluyen las instalaciones de incineración destinadas al tratamiento de residuos sólidos urbanos cuando su eficiencia energética resulte igual o superior a: 0,60 (tratándose de instalaciones en funcionamiento y autorizadas conforme a la legislación comunitaria aplicable desde antes del 1 de enero de 2009) o 0,65 (tratándose de instalaciones autorizadas después del 31 de diciembre de 2008) aplicando la siguiente fórmula:

Eficiencia energética = (Ep - (Ef + Ei)/(0,97 x (Ew + Ef)).

Ep es la energía anual producida como calor o electricidad, que se calcula multiplicando la energía en forma de electricidad por 2,6 y el calor producido para usos comerciales por 1,1 (GJ/año). Ef es la aportación anual de energía al sistema a partir de los combustibles que contribuyen a la producción de vapor (GJ/año), Ew es la energía anual contenida en los residuos tratados, calculada utilizando el poder calorífico neto de los residuos (GJ/año) y Ei es la energía anual importada excluyendo Ew y Ef (GJ/año).

También hay otras opciones de valorización como el R3 reciclado o recuperación de sustancias orgánicas que no se utilizan como disolventes (incluidos el compostaje y otros procesos de transformación biológica). Esto incluye la gasificación y la pirólisis que utilizan los componentes como elementos químicos.

El R5 (reciclado o recuperación de otras materias inorgánicas) incluye la limpieza del suelo que tenga como resultado la valorización del suelo y el reciclado de materiales de construcción inorgánicos.

El R12 (intercambio de residuos para someterlos a cualquiera de las operaciones enumeradas entre R1 y R11) es cuando no hay código R apropiado, pueden quedar incluidas aquí las operaciones iniciales previstas a la valorización, incluido el tratamiento previo, tales como, entre otras, el desmontaje, la clasificación, la trituración, la compactación, la peletización, el secado, la fragmentación, el acondicionamiento, el reenvasado, la separación, la combinación o la mezcla, previas a cualquiera de las operaciones enumeradas de R1 a R11.

Las principales ventajas del sistema son:

1) Sostenibilidad medioambiental y social

2) Dar valor al residuo hasta ahora no aprovechable como la energía eléctrica y/o biocombustible.

3) Recuperación de calor.

4) Instalación de vertido mínimo, reduciendo al máximo la necesidad de vertederos.

5) No producción de otros residuos de difícil tratamiento

6) Ahorro de emisiones de CO2 y gases de defecto invernadero por la producción de energía renovable y eliminación del vertedero.

Selección del material

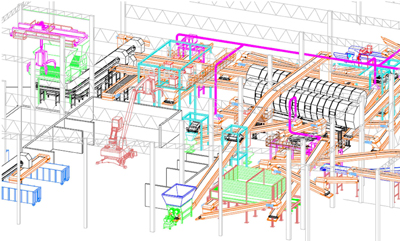

Los residuos se pueden separar según distintos factores. Uno de ellos es la separación por tamaño, mediante la utilización de cribas rotativas (trómeles) se consigue la separación del flujo de residuo en 2 ó 3 fracciones de diferentes tamaños. Hay tres tipos de fracciones: la fracción fina (fracción húmeda y orgánico que se verán sometidos a un proceso biológico posterior), la fracción intermedia (gran cantidad de envases que se triarán posteriormente como el PET, PEAD, briks, botes y latas metálicas), y la fracción gruesa (principalmente otros recuperables de mayor tamaño como papel, cartón, film y otros).

Otro tipo de separación puede ser por forma y densidad mediante la utilización de varias zarandas accionadas por sistema de doble eje cigüeñal solidarios (o de una sola zaranda si es de rampa) y con la regulación de su ángulo de inclinación se consigue la separación del flujo de residuos en varias fracciones en función a su forma y comportamiento físico. También pueden incorporar aspiración neumática.

Una tercera selección es la automática de metales. Mediante la utilización de un potente electroimán se atraen los elementos férricos que se encuentran en el flujo del residuo hasta una cinta enervada encargada de extraerlos de su zona de influencia para su recuperación. Mediante un rotor magnético situado al final de una cinta transportadora y provisto de imanes permanentes de alta remanencia se crea un campo magnético de alta frecuencia que induce las corrientes de Foucault en las piezas metálicas conductoras (aluminio). Éstas, por su parte, crean un campo magnético opuesto al del rotor por lo que son repelidas. En la selección automática de otros materiales, el residuo entra en una cinta aceleradora donde un sensor de rayos infrarrojos detecta el material a seleccionar en función a la longitud de onda de la luz que refleja. El ordenador asociado detecta la posición del material y en función de la velocidad de la cinta activa uno de los sopladores de aire comprimido que se encuentran al final de la misma, separándolo del resto.

Otro tipo de selección es la selección manual de recuperables que se consigue mediante la intervención de operarios colocados a pie de cinta que recuperan diversos materiales de manera completamente manual. Los materiales recuperados se acopiarán (generalmente en trojes bajo cabina) quedando a la espera del acondicionamiento previo a su comercialización.

Compostaje

En este apartado encontramos distintos tipos de compostaje. Uno de ellos es el compostaje en parva o meseta (fermentación aerobia de la fracción orgánica del residuo municipal en parvas o mesetas tanto en exterior como en nave cubierta o cerrada). Se controla el nivel de oxígeno, temperatura y humedad mediante volteos y riegos periódicos del material con vehículos especiales (volteadoras). Otro tipo de compostaje es el que se aplica en un túnel (fermentación aerobia de la fracción orgánica del residuo municipal en túneles cerrados). Los niveles de oxígeno, la temperatura y humedad se controlan permanentemente mediante un sistema informático que acciona el riego o la impulsión o aspiración de aire a través de la masa del residuo. Este sistema constituye un proceso estático donde el material introducido en el interior del túnel no se mueve hasta la finalización del proceso de compostaje.

También se usa el compostaje en trincheras, donde los niveles de oxígeno, la temperatura y humedad se controlan permanentemente mediante un sistema informático que acciona la impulsión o aspiración de aire a través de la masa del residuo. El sistema se completa con el volteo y riego periódico de la masa de residuo mediante un vehículo especial (volteadora). La carga y descarga de las trincheras puede ser automática.

El compostaje mediante reactor de eje vertical (fermentación aerobia de la fracción orgánica del residuo municipal en reactor cerrado con volteo automatizado) consigue que los niveles de oxígeno, la temperatura y humedad se controlen permanentemente mediante un sistema informático que acciona la aspiración de aire a través de la masa de residuo. El sistema se completa con el volteo y riego periódico de la masa de residuo mediante un puente grúa dotado de carro con tornillos helicoidales que van desplazando transversalmente el producto. La carga y descarga del reactor también está automatizada.

Por otro lado también existe el compostaje mediante un reactor con eje horizontal. En este caso, los niveles de oxígeno, la temperatura y humedad se controlan permanentemente mediante un sistema informático que acciona la impulsión de aire a través de la masa del residuo. El sistema se completa con el volteo y riego periódico de la masa de residuo mediante un puente grúa dotado de carro con rotopala que va desplazando longitudinalmente el producto.

Biometanización

La biometanización es un proceso anaerobio de descomposición de la materia orgánica mediante el que se obtiene una fracción gaseosa llamada biogás, que puede ser utilizado para la producción de electricidad, de calor y de electricidad combinadas, o como combustible para vehículos; y un material digerido, que normalmente es un sólido de consistencia pastosa, con un contenido elevado de nutrientes para las plantas.

La biometanización se puede producir por distintas vías, entre ellas destacan:

- Vía seca: digestión anaerobia de la fracción orgánica del residuo municipal en reactor para la obtención de biogás con un elevado contenido de metano (55-60%). El contenido de sólidos en el digestor es elevado (30-40%). El movimiento del residuo dentro del digestor puede ser con acción mecánica o mediante la recirculación del propio biogás.

- Vía húmeda: digestión anaerobia de la fracción orgánica del residuo municipal en reactor para la obtención de biogás con un elevado contenido de metano (55-60%). El contenido de sólidos en el digestor es relativamente bajo (6-10%) por lo que necesitamos preparar una suspensión añadiendo agua previamente a la digestión.

- Pretratamiento seco de la MOR: los tratamientos mecánicos sencillos que seleccionan la fracción orgánica del residuo orgánico (cribado+separación de metales) son solo válidos para compostaje, no para procesos de biometanización ya que junto a ésta aparecen además numerosos materiales no biodegradables como arenas, vidrios, escombros, pequeños plásticos, cáscaras duras de frutas, etc. Así la teórica fracción orgánica obtenida, como producto pasante por la criba citada, realmente contiene entre un 25 y 40% de elementos no apropiados para la biometanización. Estos elementos ‘impropios’ no solo son difícilmente biodegradables, sino que entorpecen el funcionamiento general de la instalación produciendo atascos, decantaciones no controladas de arenas, vidrios y otros áridos, así como segregación de capas de elementos flotantes no deseados reduciendo la capacidad efectiva de la biometanización.

- Pretratamiento húmedo de la MOR: en el caso de las biometanizaciones vía húmeda podemos aumentar la eficiencia del pretratamiento seco con un sistema de eliminación de impropios añadido al sistema de preparación de la suspensión (hidropulper). De esta forma, la concentración de impropios del material que finalmente enviamos a digestión disminuye significativamente.

Biosecado y estabilización

En el biosecado los procesos de fermentación aerobia de la fracción orgánica tienen además otra utilidad, la de reducir la humedad del residuo que aprovechan la fermentación aerobia (reacción exotérmica con excedente de calor). De esta forma, controlando la humedad y mediante el uso de un sistema de aspiración de aire forzado se consigue, además de la estabilización de la materia orgánica contenida en el residuo (por fermentación aeróbica), la reducción de su grado de humedad por debajo del 20%, y por tanto la reducción de su peso produciendo un material de alto PCI que puede ser valorizado como combustible. Este sistema se puede utilizar con fracciones mezcladas sin tratamiento mecánico de selección previo.

Esta información se ha obtenido de la pasada edición de Reinnova, Congreso Internacional de Innovación en la Gestión y Tratamiento de los Residuos Municipales, que tuvo lugar en Sabadell los pasados 1 y 2 de julio de 2009, donde Carlos Guijarro Castro, director técnico de Sufi, expuso en una conferencia el tratamiento mecánico biológico de residuos urbanos.