Rastelli Raccordi presenta el anillo de cierre AR3

Anillos para montajes en circuitos oleohidráulicos y neumáticos

Departamento técnico de Rastelli Raccordi01/02/2004

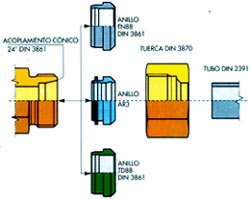

El nuevo anillo de cierre AR3 de Rastelli Raccordi, además de las características conocidas y comprobadas propiedades funcionales de los anillos de cierre convencionales de hoja simple o doble, destaca por su sujeción doble opuesta, su estanquidad absoluta, cierre automático, facilidad de montaje y por ser intercambiable con todos los racores de anillo cortante 24º DIN 2353.

El anillo de cierre AR3 de nueva creación ha sido estudiado y desarrollado por Rastelli Raccordi para ofrecer a los usuarios un producto perfeccionado. Este anillo, además de las características conocidas y las comprobadas propiedades funcionales de los anillos de cierre convencionales de hoja simple (TN88) o doble (TD88), destaca por las particularidades siguientes:

- Sujeción doble, opuesta

- Estanquidad absoluta

- Cierre automático

- Facilidad de montaje, con posibilidad de sustituir la junta de elastómero

- Reducción de la fuerza aplicada al montaje

- Es intercambiable con todos los racores de anillo cortante 24º DIN 2353 (ISO 8434-1).

Garantía de experimentación, pruebas y ensayos

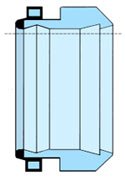

El anillo de cierre AR3 (figura 1) ha sido estudiado, diseñado y ensayado conforme a los procedimientos utilizados para el control y la verificación durante el desarrollo de nuevos productos, según UN Flow Chart definido por la certificación ISO 9001, que Rastelli Raccordi ha puesto en marcha organizando la estructura de su empresa.

Figura 1

Esquema de identificación del producto

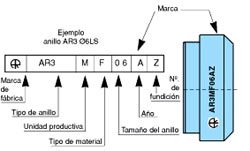

Los anillos AR3 están provistos de una señal de identificación cuya clave es la representada en la figura 1A.

Figura A1

Sujeción doble, opuesta

Con el nuevo sistema de hoja doble opuesta se obtiene más seguridad a las presiones máximas, bajo cargas extremas, sacudidas y golpes de ariete, así como menor probabilidad de soltarse y resistencia más alta a las vibraciones.

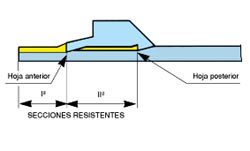

La distancia entre las dos hojas y la geometría especial de la hoja posterior (figura 2) crea, en la fase de apriete, una segunda sección de material resistente sobre el tubo que, sumándose a la primera sección de material resistente, creada por la hoja anterior, determina un incremento de más del 40 por ciento del nuevo anillo AR3 comparado con el anillo normal de la hoja doble TD88.

Figura 2

Estanquidad absoluta

Gracias a la forma particular del anillo AR3 en su extremidad axial correspondiente a la hoja anterior se ha podido insertar una junta de elastómero (figura 3) que se pone en el asiento cónico de 24º de cuerpo racor y queda unida al anillo por medio de una arandela sobre la cual ha sido vulcanizada.

Figura 3

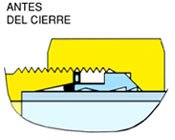

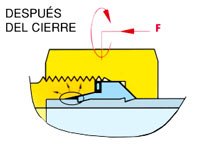

En la primera fase de cierre, el anillo AR3, empujado por la tuerca sobre el cono 24º del racor, provoca la separación de la junta de elastómero de la arandela colocándose como indica la figura 4.

Es fundamental la posición de esta junta que, bajo la presión P del fluido y precomprimida por la fuerza F debida al apriete del anillo AR3 sobre el tubo, asegura un cierre hermético o estanco perfecto (figura 4).

Figura 4

Límite automático de cierre

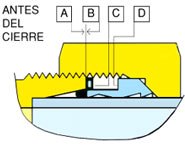

El cierre automático del anillo AR3 sobre el cuerpo del racor ocurre cuando por efecto del atornillamiento de la tuerca, el anillo AR3 se desliza por el cono de 24º del cuerpo racor (figura 5) hasta que las dos superficies C y D están en contacto formando un conjunto con las otras dos superficies A y B, previamente unidas en la primera fase de montaje, de modo que el operario debe dejar de apretar.

Figura 5

Por este sistema se garantiza el agarre más eficaz del anillo AR3 en el tubo. Sólo se aconseja comprobar, tras aflojar la tuerca, que las dos superficies C y D estén perfectamente en contacto a lo largo de toda la circunferencia.

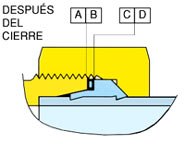

En la fase final de apriete (figura 6), la arandela, separada de la junta de elastómero, tiene la función de compensar desconcentrados eventuales debidos a la suma de las tolerancias de los distintos componentes (cuerpo, tubo, anillo, tuerca), comprimiéndose hasta formar un todo con el cuerpo racor y el anillo AR3.

Figura 6

Facilidad de montaje

Con el nuevo anillo de cierre AR3 se eliminan aquellas operaciones y maniobras que obligan al montador a comprobar el engarce del anillo en el tubo por medio de controles laboriosos como:

- Marcar el tubo y la tuerca para verificar el número de vueltas de la misma y tener así la certeza de un cierre adecuado.

- Emplear llaves dinamométricas para la verificación de la fuerza (Nm) necesaria para el cierre.

Para simplificar la manipulación de los diversos elementos durante el montaje, el anillo de cierre AR3 y la junta de elastómero vulcanizada sobre la arandela se suministran ya acoplados.

Instrucciones para el montaje

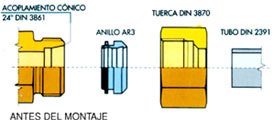

Para el montaje del nuevo anillo AR3 (figuras 7 y 8) valen las recomendaciones incluidas en las instrucciones para el montaje de un anillo normal Rastelli TN88-TD88 acerca de la lubricación de las piezas, la limpieza de los órganos, la ortogonalidad de las cabezas del tubo, el apoyo del tubo sobre el plano de tope del racor, etc.

Figura 7

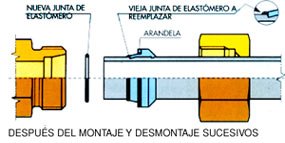

Las operaciones sucesivas de montaje y desmontaje pueden ser numerosas, pues si es necesario se puede sustituir (figura 8) sólo la junta de elastómero, ya que el anillo AR3 queda fijado al tubo y la arandela, acoplada al anillo.

Figura 8

Reducción de la fuerza aplicada al montaje

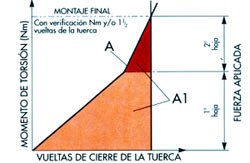

En comparación con los anillos de cierre normales TD88 (hoja doble), los AR3 necesitan menos trabajo para llegar al final del cierre, pues la fuerza empleada en el montaje es sensiblemente menor. La figura 9A presenta el curso del momento de torsión en función de las vueltas de cierre de la tuerca empleando un anillo TD88.

Como se puede apreciar en este gráfico (línea A), el momento de torsión va creciendo desde el comienzo del cierre y resulta imposible al montador percibir claramente el final del montaje del mismo.

Figura 9A

Al contrario, en el gráfico del anillo AR3 (figura 9B-línea B), el curso del momento de torsión con arreglo de las vueltas de cierre de la tuerca aumenta más débilmente respecto a la figura 9A, hasta llegar a una cuesta empinada que señala de modo inconfundible al montador que el trabajo está acabado (cierre automático) evitando la vuelta de más que podría dañar el cierre.

La diferencia entre las zonas A1 y B1 representa el trabajo economizado al montaje utilizando el anillo de cierre AR3 en lugar de los anillos de cierre tradicionales.

Figura 9B

Intercambiabilidad

Los nuevos anillos AR3 son intercambiables con los demás anillos de cierre de hoja simple o doble que se utilizan con los racores de cono 24º DIN 2353 (ISO 8434-I).

Con el anillo AR3 se pueden emplear los mismos utensilios de premontaje manual (bloques templados tipo TN I 95) habitualmente usados con los anillos de cierre normales TN88-TD88.

Debido a la característica de estanquidad absoluta del anillo AR3, su empleo está especialmente indicado para todos los racores con junta NBR (junta flexible): ausencia de escape y transpiración y tubos secos en el exterior.

Se aconseja de modo particular el empleo de racores de la serie TN 400 (TN 419-420-421-426-432) que sustituyen a los TN 119-120-121-126-132, que no se entregan precerrados, pero que pueden ser utilizados apretando el anillo AR3 sobre el acoplamiento túbico del racor directamente durante el montaje.

Figura 9

Datos técnicos

- Acabado de la superficie: tratamiento de abrillantado al cromo (galvanización blanca).

- Materiales y temperaturas de trabajo máximas admisibles “TB” (DIN 2401). Piezas de metal: acero, piezas de caucho: NBR.

- Presiones: la presión nominal PN corresponde a un coeficiente de seguridad de PN x 4. Las presiones indicadas se entienden como máximas de trabajo, incluidos los valores máximos en condiciones normales de trabajo y con temperaturas de trabajo máximas admisibles TB (DIN 2401). Para anillos AR3 con juntas de caucho, se ruega observar las disposiciones de la norma DIN 7716 “Productos de caucho”. Requisitos para el almacenaje, la limpieza y la manutención.