Las plantas de ciclo combinado como solución a la creciente demanda energética

Para cumplir con el incremento de la demanda de energía eléctrica, el sistema eléctrico español ha impulsado el desarrollo de las energías renovables, entre las que destacan la energía eólica y solar que, dados sus costes, capacidad y variabilidad de suministro, no pueden hacer frente de forma fiable al importante crecimiento de demanda previsto para los próximos años. Esta circunstancia, unida a los compromisos firmados por el Gobierno español en el Protocolo de Kioto, confiere un carácter imperativo a la implantación de tecnologías que funcionen con combustibles fósiles cuya eficiencia sea mucho mayor y cuyas emisiones hagan de ésta una tecnología más limpia. Por ello, las centrales térmicas de ciclo combinado son una gran alternativa, ya que son capaces de dotar al sistema eléctrico de la seguridad y fiabilidad.

La tecnología de generación eléctrica con ciclos combinados es una de las más eficientes y con menor impacto ambiental, y, por esta razón, está ya ampliamente extendida en el mundo. Se trata de un sistema que permitirá ir sustituyendo, junto a las energías renovables, a los ya tradicionales, con la consiguiente reducción de emisiones. Por sus características medioambientales, dado que sus emisiones específicas por cada kWh de energía eléctrica generado son mucho menores que las producidas por las centrales térmicas convencionales, esta tecnología está apoyada e impulsada por el estado español en su planificación plurianual de los sectores de electricidad y gas y por los propios esstados europeos, que reconocen la necesidad de aumentar la capacidad de generación de acuerdo a criterios de respeto medioambiental.

¿Qué es una central térmica de ciclo combinado?

La tecnología de ciclo combinado para la generación de energía eléctrica es la que mejor armoniza la eficiencia y el respeto medioambiental, debido a que combina el potencial directo de la combustión, generalmente de gas natural, y el del vapor que se obtiene por reutilización de los gases residuales de dicha combustión, todavía calientes, para generar electricidad. Es decir, que a partir de una misma fuente energética primaria, generalmente gas natural, se obtiene electricidad en dos etapas. La primera, basada en turbina de gas, que genera directamente electricidad a partir de la combustión. Y la segunda, que reutiliza en una caldera de recuperación de calor la energía contenida en los gases calientes sobrantes de la primera etapa para generar vapor de agua, el cual se aprovecha mediante turbina de vapor para generar más electricidad. La eficiencia combinada de todo el proceso está comprendida entre el 55% y el 60%, frente al entre el 30% y el 40% de las plantas de energía eléctrica que utilizan una sola etapa de transformación de la energía contenida en el combustible.

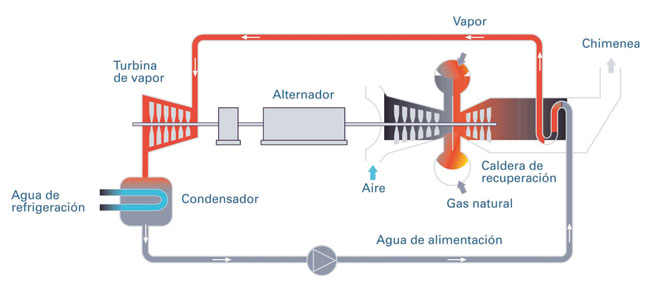

Básicamente, un ciclo combinado está compuesto por una turbina de gas, una caldera de recuperación de calor, una turbina de vapor, un condensador y un generador eléctrico o alternador, además de todos los servicios auxiliares requeridos (resto de planta) para obtener un sistema capaz de producir electricidad. Las centrales térmicas de ciclo combinado pueden clasificarse atendiendo al tipo de combustible que utilizan y, por otro lado, según la configuración y disposición de sus equipos principales.

Considerando el tipo de combustible utilizado, las plantas de ciclo combinado pueden ser de gas natural, gasóleo, o mixtas, aunque se preferirá normalmente la utilización de gas natural por ser éste el combustible fósil más limpio disponible: no contiene azufre y produce menos CO2 para la misma energía generada (menor relación C/H). Así, en el caso de las centrales de ciclo combinado mixtas, el combustible base utilizado prácticamente durante todo el tiempo de operación será el gas natural y el combustible alternativo, al que se recurrirá exclusivamente en caso de emergencia, será el gasóleo. En cuanto a su configuración, una planta de ciclo combinado puede disponer de una o varias turbinas de gas, conectadas a su propia caldera de recuperación de calor que, a su vez, alimentan a sendas o a una única turbina de vapor. Y atendiendo al número de ejes principales de que consta un grupo de ciclo combinado, se puede hacer una nueva clasificación en función de la disposición relativa de los ejes de las turbinas de gas y vapor, si se encuentran en una misma línea y acoplados o no, hablándose en este caso de configuraciones monoeje y multieje.

¿Cómo funciona una central de ciclo combinado?

El proceso de generación de energía eléctrica en una planta de ciclo combinado comienza con la admisión de aire desde el exterior, el cual es conducido al compresor de la turbina de gas, a través de sucesivas etapas de filtrado, para ser comprimido y, a continuación, mezclado con el combustible, generalmente gas natural, en la cámara de combustión. En ésta, tras iniciarse y mantenerse el proceso de combustión, se produce de forma continua la oxidación del combustible en presencia de oxígeno. El resultado es un flujo de gases calientes que, al expandirse, hacen girar la turbina de gas proporcionando trabajo útil; un alternador permite transformar dicho trabajo útil en energía eléctrica.

Los gases de escape que son expulsados de la turbina de gas (600 °C) conservan aún una parte importante de la energía térmica que adquirieron en la combustión, aproximadamente el 60%, por lo que pasan para su aprovechamiento a la caldera de recuperación de calor, donde se extrae la mayor parte del calor aún disponible en los gases de escape produciendo vapor de agua a presión en las condiciones requeridas por la turbina de vapor. Posteriormente son conducidos a la chimenea de evacuación, donde son liberados a la atmósfera a una temperatura muy inferior (entre 90 °C y 100 °C).

El vapor que sale de la turbina de vapor pasa a un condensador donde se transforma en agua. Este condensador es refrigerado mediante aire o agua, de forma que se consigue la disipación del calor latente contenido en el vapor al agua de enfriamiento o a la atmósfera. Posteriormente, el agua resultante de la condensación es bombeada a alta presión hasta la caldera de recuperación para iniciar nuevamente el ciclo agua-vapor.

Aspectos medioambientales

Frente a las centrales térmicas convencionales, basadas en la combustión de carbón o fuel-oil, los ciclos combinados utilizan gas natural como combustible base. Atendiendo a las emisiones específicas por kWh de energía eléctrica generada, si se considera junto a la utilización del gas natural como combustible base el efecto de su alta eficiencia, la ventaja aportada por los ciclos combinados es clara en comparación con la generación convencional a partir de carbón o fuel-oil, permitiendo alcanzar reducciones promedio de hasta el 60% en las emisiones de dióxido de carbono, de hasta el 57% en las de óxidos de nitrógeno y la práctica eliminación de las de compuestos sulfurados y partículas; todo ello para la obtención de una misma cantidad de energía eléctrica. Así se reconoce en los países con reglamentaciones estrictas para proteger el medio ambiente, donde el consumo de gas natural está creciendo en aplicaciones en las que se reduce la contaminación.

Para generar una misma cantidad de energía eléctrica, los ciclos combinados precisan de hasta un 35% menos de consumo de combustible que las centrales convencionales y un consumo de agua reducido frente al de aquellas (1/3 de lo que consume una central de ciclo simple de fuel o carbón) debido a que la turbina de gas no precisa de refrigeración alguna y únicamente se requiere agua para el ciclo de agua-vapor. En la actualidad, las emisiones de NOx están controladas en los ciclos combinados por el uso de quemadores de premezcla por vía seca de bajo NOx y las emisiones de CO a través de la reacción completa en la cámara de combustión, lo que se logra mediante la selección de unos equipos con el diseño adecuado, el empleo de sistemas de control y monitorización. En cuanto a los vertidos que se generan, los distintos efluentes son tratados antes de su vertido. Los residuos sólidos y líquidos son pocos en este tipo de instalaciones, y la mayoría de ellos provienen de las operaciones de mantenimiento o son residuos del tratamiento de aguas. Cuando no pueden ser tratados en los sistemas instalados en la planta, se entregan a un gestor autorizado. Por otra parte, en los ciclos combinados existen fuentes de ruido, como ventiladores, bombas, turbinas, sistemas de vapor, torres de refrigeración y transformadores, que cumplen con la legislación laboral y medioambiental vigente. Los criterios para la mitigación de ruidos contemplan recintos con medidas especiales de atenuación y silenciadores en la entrada de aire y salida de los gases de escape.

Y aún existen más ventajas...

Los ciclos combinados requieren menores plazos de construcción y entrega que las centrales térmicas convencionales, así como una menor inversión inicial, lo que permite reducir los plazos de amortización. Existe una gran modularidad y normalización en su diseño, lo que dota de homogeneidad a la tecnología. Además, presentan mayor flexibilidad operativa y, con ello, menores tiempos de arranque y parada y mayores capacidades de regulación, y requieren menos espacio y menor volumen de edificación, lo que permite reducir su impacto visual y territorial.

El Plan Nacional de Asignación de Derechos de Emisión prevé una mayor generación con gas natural y con energías renovables para reducir la generación con carbón y con fuel-oil, menos eficientes y más contaminantes. La previsión hasta 2012 considera una reducción del 3,7% anual en la utilización de carbón y un incremento mayor del 9% anual en la de gas natural. Por ello, actualmente hay en España más de 40 grupos de ciclo combinado funcionando o de próxima entrada en servicio.

El ejemplo de Gas Natural como apuesta por el ciclo combinado

La estrategia del Grupo Gas Natural en el negocio de generación eléctrica está centrada en disponer de un mix de producción equilibrado, competitivo y respetuoso con el medio ambiente, basado en ciclos combinados y energías renovables, y en línea con los objetivos del Protocolo de Kioto. La reciente integración en el Grupo Gas Natural de la eléctrica Union Fenosa, hace que en estos momentos el grupo haya consolidado su posición dentro del mercado eléctrico español.

En estos momentos la compañía cuenta con 7.600 MW operativos en ciclo combinado gracias a sus diez centros en La Plana del Vent (Tarragona, 800MW); Palos de la Frontera (Huelva, 1.200 MW); Campo de Gibraltar (Cádiz, 800 MW –a 50% con Cepsa–); Sant Adrià de Besòs (Barcelona, 400 MW); San Roque (Cádiz, 400 MW); Arrúbal (La Rioja, 800 MW); Cartagena (Murcia, 1.200 MW); Sagunto (Valencia, 1.200 MW); Sabón (A Coruña, 400 MW); y Aceba (Toledo, 400MW). Asimismo, la compañía tiene en construcción un ciclo combinado de 400 MW en Málaga y dos grupos, 800 MW en total, en el puerto de Barcelona, que se espera que entren en funcionamiento durante este 2010.